Print Costed Bill Of Material prints a selected

range of parent items and "rolls up" their costs from the costs of

their components. If you choose, it will show the variance between the parent

items' cost on file and the cost calculated from the components. It also

allows you to choose whether or not you wish the report to show active items,

obsolete items and/or forecasted items.

As the costs are rolled up from the bill of

material, it will explode through sub-assemblies if they are flagged as

manufactured. It will not explode through any purchased inventory items. This

is regardless of whether the items are flagged as stocked or non-stocked. If a

sub-assembly is flagged as a purchased item, this is an error in the product

structure and may be corrected using the Product Structure File Maintenance

application.

An important feature of this application is the

ability to update the cost in the Inventory Item File for the range of parent

items selected. If the update cost option is chosen, the number of levels to

explode will automatically be set to 11. Caution: Only parent items'

sub-assemblies within the item range defined in fields #1 and #2 will have

their costs updated. To avoid excluding any sub-assemblies, set the item range

to All.

It also offers the option to include components'

scrap factor in the calculated cost for each.

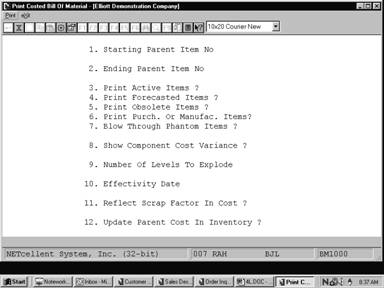

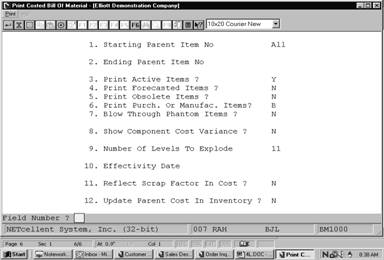

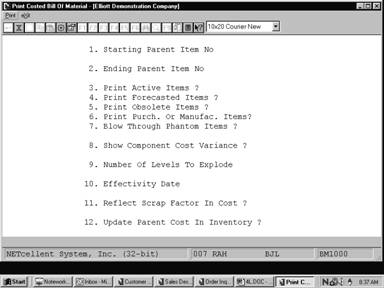

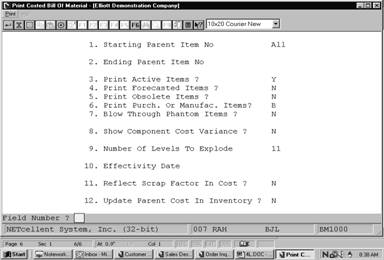

Select Print Costed Bill Of Material from the pull

down BOMP Processing window. The following screen will then be displayed:

Print Costed Bill of Material Entry Screen

The following options are

available:

* Select the

desired mode from the Print Costed Bill Of Material menu bar

* Enter the

data requested on the screen

To return to the menu bar,

press the ESC or F10 key. To leave this application, press X for EXIT when

positioned at the menu bar.

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

1. Starting Parent Item

No

|

15 alphanumeric characters.

Enter the item number of the parent item for which you

wish to print a Print Costed Bill Of Material.

Default is All.

|

|

2. Ending Parent Item

No

|

15 alphanumeric characters.

Enter the item number of the last parent item for which

you wish to print a Print Costed Bill Of Material.

Default is the starting

parent item number.

|

|

3. Print Active Items?

|

Y or N.

Enter Y to print active items or N to decline.

This field defaults to Y.

|

|

4. Print Forecasted

Items?

|

Y or N.

Enter Y to print forecasted items or N to decline.

This field defaults to N.

|

|

5. Print Obsolete

Items?

|

Y or N.

Enter Y to print obsolete items or N to decline.

This field defaults to N.

|

|

6. Blow Through

Phantom Items?

|

Y or N.

Component items and subassemblies which are neither

stocked nor controlled but which are manufactured are known as phantom

items. Answering Y to this question allows you to blow through phantom items

to the real component items, which are down one level.

Default is N.

|

|

7. Show Component

Cost Variance?

|

Y or N.

If you answer Y to this question the variance between

the calculated cost of the parent item and the cost that is in the Item File

for this parent, will appear on the report.

Default is N.

|

|

8. Number Of Levels

To Explode?

|

2 numeric digits (99).

The number of levels to explode must be 11 to obtain

correct cost.

Default is 11.

|

|

9. Effectivity Date

|

A date in the standard date

format.

Enter the effectivity date you wish to use for printing

items. This date will be used to determine whether to include or exclude

items. If you press RETURN, no selection will be made based upon effectivity

date.

You will not be prompted to enter this field unless

both active and forecasted have been selected for printing.

Default is no selection

based on effectivity date.

|

|

10. Reflect Scrap Factor

In Cost?

|

Y or N.

Enter Y to include each

component's scrap factor in the calculation of the extended cost. Enter N to

calculate the extended cost based solely on the quantity required per

parent. Defaults to N.

|

|

11. Update Parent Cost

In Inventory?

|

Y or N.

If you answer Y, the appropriate cost in the Inventory

Item File for the parent item will be updated using the total cost of

components for the parent.

If Y is selected, the number of levels to explode set

in field #8 will automatically be set to 11.

Note: If you set this field to Y but do not select All

parent items in field #1, the costs of all sub-assemblies may not be

updated. If it is important that the costs of all sub-assemblies be updated,

set the parent item range to All.

Default is N.

|

|

If the costing method defined in I/M Setup is LIFO or

FIFO, parent costs may not be updated and field #11 will appear as follows:

|

|

11. Cost Type To Display?

|

Only A, S, or R, is allowed.

Enter the item cost to be used in printing the Costed

Bill of Material.

A = Average

Cost

S = Standard

Cost

R = Last

Cost

Entry is required. There is

no default value.

|

ScreensREPORTS

ScreensREPORTS

Print Costed Bill of Material

C O S T E D B I L L O F M A T E R I A L

Ranges:

All Items

Active Items

With No Blow Through

No Selection On Basis Of Effectivity Date

Parent

Item CPU Mother Board For Parent Low Level Code 1 Cost

On File 2,103.4900

Central Processing

Component

Item Seq Low Lev Component Purchased Act Scrap

Uom Qty Per Item Extended

No Code Description Or Mfg Flag Factor

Parent Std Cost Cost

CLOCK

10 2 25 Meg Clock For Mother Board P A .0 EA

1.000000 12.5400 12.5400

Clock ‑ 25M

DATA‑BUS

20 2 Data Bus/Buffer 25 Meg P A .0 EA

1.000000 15.4500 15.4500

Data ‑ Buffer

MEMMGR

30 2 Memory Manager For CPU Board P A .0 EA

1.000000 44.0000 44.0000

MEM ‑ Manager

VGA

40 2 Monitor / Rom P A .0 EA

1.000000 230.0000 230.0000

Monitor ‑ Rom