BOMP Setup, like Company Setup, is not an

application that you will need to run frequently. Through this application you

will answer some questions that will have a bearing on the way other

applications in the package will run.

BOMP Setup is a very simple application, which

allows you to add or change some key information in the BOMP Control File.

However, the answers you give will affect the way in which other applications

will run, so be sure to answer the questions in accordance with your real

needs.

For example, companies can elect to keep an audit

trail of the Product Structure File that monitors the file for additions and

deletions of records as well as for changes to fields within the records.

Other companies may choose not to keep this audit trail.

This audit trail is kept automatically by the

Product Structure File Maintenance application only if selected here in Setup.

Several other yes/no option flags are set in BOMP

Setup. These are the options to use job numbers to track production; the

ability to change order prices during order processing; the option to display

item costs on screens and reports; and the option to use serial/lot batch numbers

with appropriate items.

This Setup application also provides for the

optional entry of a user‑defined field which becomes the name of the last

field entered into the product structure record during Product Structure File

Maintenance.

Other options available through BOMP Setup include

establishing the production order and engineering change numbers. These will

be automatically incremented when production orders and engineering changes are

entered in the appropriate applications. BOMP Setup also assigns default work

in process (WIP) account numbers for tracking materials during the production

process.

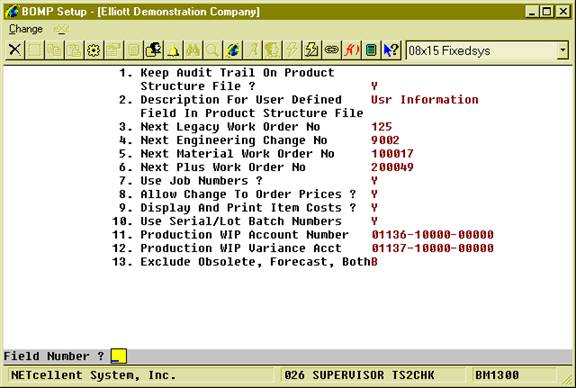

Select BOMP Setup from the

pull down BOMP Util_setup window and the following will be displayed:

BOMP Setup Entry Screen

The following options are

available:

* Select the

desired mode from the BOMP Setup menu bar

* Enter the

data requested on the screen

Note: If this is the

first time that you have run BOMP Setup, then the program will ask you to enter

the data for each of the fields on the screen. If this program has been run

previously, the data entered at that time will be displayed and may be changed

accordingly.

To return to the menu bar,

press the ESC or F10 key. To leave this application, press X for EXIT when

positioned at the menu bar.

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

1. Keep Audit Trail On

Product Structure File?

|

Y or N.

Your answer here determines

whether or not changes to the Product Structure File will be recorded for

later audit. Default is N.

|

|

2. Description

For User Defined Field In Product Structure File

|

15 alphanumeric characters.

Entry of this field is

optional. This entry determines the name of an informational field in the

product structure record. Since that field is informational and is not used

by the package for processing, there are no additional restrictions to what

may be entered here.

|

|

3. Next Legacy Work

Order No

|

6 numeric digits.

Enter the next Legacy Work

Order number to be used during entry of production orders.

|

|

4. Next Engineering

Change No

|

6 numeric digits.

Enter the next Engineering

Change number to be used during entry of engineering changes.

|

|

5. Next Material Work

Order No

|

6 numeric digits.

Enter the next Material Work

Order number to be used during entry of production orders.

|

|

6. Next Plus Work Order

No

|

6 numeric digits.

Enter the next Plus Work

Order number to be used during entry of production orders.

|

|

7. Use Job Numbers?

|

Y or N.

Enter Y to use Job Numbers

to track production related to a specific job. If N is entered, the user

will still be allowed to enter information in Job Number fields in BOMP

applications, but this information will not be posted to the Job History

File. Default is N.

|

|

8. Allow Change To

Order Prices?

|

Y or N.

Enter Y to allow the user to

change unit prices in the Feature/Option Configuration and Production Order

Entry applications. Default is N.

|

|

9. Display And Print

Item Costs?

|

Y or N.

Enter Y to display and print

item costs in the applicable BOMP application. Enter N to prevent item costs

from being displayed. Default is N.

|

|

10. Use Serial/Lot Batch

Numbers?

|

Y or N.

Enter Y to allow the use of

serial/lot batch numbers in tracking serial/lot items. This provides greater

flexibility in tracking and the ability to increment serial/lot numbers when

producing large quantities. Default is N.

|

|

11. Production WIP

Account Number

|

An account number in the

standard account number format.

Enter the account to be used

for tracking work in process (WIP). This account will keep track of the

value of materials allocated during production until a finished item is

reported. Entry is required.

|

|

12. Production WIP

Variance Account

|

An account number in the

standard account number format.

Enter the account to be used for the variance in the

value of components between when they are allocated and when a finished item

is reported.

This account will only be

used if an order is flagged as complete before all ordered items are

produced. This would require that the value of unused components be

transferred back from the WIP account to the various inventory asset

accounts. If there was a change in the value of any of the component items

during the production process, this account will show the variance.

|

|

13. Exclude Obsolete,

Forecast, Both

|

O, F or B.

Enter whether obsolete or

forecast items or both should be excluded from Bill Of Material Processing.

|