The Engineering Change Processing

application allows the user to make modifications to a product structure

without immediately implementing those changes in the production process.

Modifications are stored in a separate file until the Post Engineering

Changes application is run. At that time, the user may specify which

changes are to be made to the Product Structure File.

Before they are posted, engineering changes may be

changed, deleted, and/or printed on the Engineering Change Edit List. After

posting, engineering changes may be printed using the Engineering Change

History Report application.

When making an engineering change, the user will

be prompted to enter the parent item number of the product structure to be

modified. This is followed by a brief description of what the change involves

or any other relevant information that the user wants to be printed on the edit

list and Engineering Change History report. The user will then be

prompted to enter a sequence number. Components will display and print

according to this sequence number. If the sequence number entered already

exists in the product structure, the user may choose to either change or delete

it. If the sequence number is new, it must be added to the product structure

before it can be modified. The user may then enter specific information

related to the component item. For more information on product structures,

consult the Product Structure File Maintenance application section of

this manual.

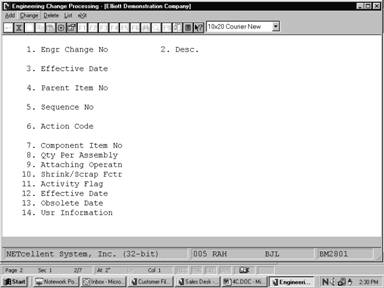

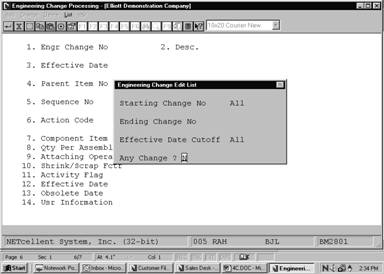

Select Engineering Change

Processing from the pull down BOMP Processing window. The following

screen will then be displayed:

Engineering Change Processing Entry Screen

The following options are

available:

* Select the

desired mode from the Engineering Change Processing menu bar.

* Enter the

data requested on the screen.

To return to the menu bar,

press the ESC key. To leave this application, press X for EXIT

when positioned at the menu bar.

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

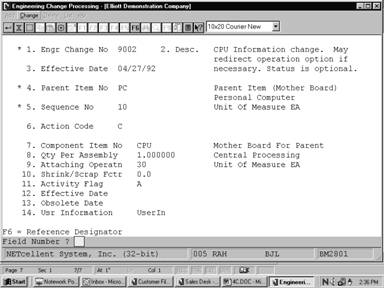

1. Engr Change No

|

6 numeric digits.

Enter the engineering change

number. In add mode, press the F1 key to bring up the next

engineering change number on file.

|

|

2. Desc.

|

3 lines of 30 alphanumeric

characters each.

Enter a description of the engineering change. This

description will be printed on the Engineering Change Edit List and the

Engineering Change History Report.

A blank description is not

allowed.

|

|

3. Effective Date

|

A date in the standard date

format.

Enter the date on which the engineering change should

become effective.

Note:

Engineering changes do not affect product structures until posted in the Post

Engineering Changes application. Default is the current date.

|

|

4. Parent Item No

|

15 alphanumeric characters.

Enter the parent item number

whose component will be affected by the engineering change. In add mode,

press the F7 key to search by item number or press the F8 key

to search by item description.

|

|

5. Sequence No

|

3 numeric digits.

Enter the sequence number, which will be used with the

parent item number in this product structure record. The sequence number may

not be zero and a parent may not have records with the same sequence number.

In add mode, press the F1

key to search for the next available sequence number in the product

structure. Press the F7 key to search existing components. In change

mode, press the F1 key to search for sequence numbers already on file

for this engineering change. Press the F7 key to search for existing

components, or the F8 key to search for engineering changes.

|

|

6. Action Code

|

1 alphabetic character.

Enter the action code representing what is to be done

to this particular sequence number. The user may enter one of three values:

A = Add

C = Change

D = Delete

If the sequence number

already exists in the product structure, it may only be changed or deleted.

If the sequence number is new to the product structure, it may only be added.

|

|

7. Component Item No

|

15 alphanumeric characters.

Enter the item number of the component to be linked to

the sequence number. If the sequence number already exists in the product

structure, the item number and description will display automatically. The

user may change the item or leave it alone.

Press the F7 key to

search for an item by number, or press the F8 key to search for an

item by description.

|

|

8. Qty Per Assembly

|

10 numeric digits with 6

decimal places and an optional minus sign (9999.999999-).

Enter the quantity per

assembly for this product structure record. This is the number of component

items needed to make one parent. Entry is not required.

|

|

9. Attaching Operatn

|

4 numeric digits.

Enter the number of the

operation in this parent's routing where this component is to be used or

attached.

|

|

10. Shrink/Scrap Fctr

|

4 numeric digits including 1

decimal place (999.9).

Enter the percentage of the

component which is anticipated to be lost due to scrap, shrinkage, etc.

|

|

11. Activity Flag

|

1 alphanumeric character.

Enter the desired value for the component's activity

flag. This flag can have one of three values:

A = Active

F = Forecasted

O = Obsolete

An active item is one currently in use or being sold to

customers.

A forecasted item is one, which is forecasted to be

active in the near future.

An obsolete item is one

which is no longer a standard part, though there may still be a supply of the

item on hand which can be sold or used in other manufacturing processes.

|

|

12. Effective Date

|

A date in the standard date

format.

Enter the effectivity date

for this component. If the item has no effectivity date, this field may be

left blank. If the item is forecasted, this is the date the item should

become active.

|

|

13. Obsolete Date

|

A date in the standard date

format.

Enter the obsolete date for

this component. If the item has no obsolete date, this field may be left

blank. If the item is active, this is the date the item should become

obsolete.

|

|

14. Usr Information

|

6 alphanumeric characters.

The name for this field may be defined by the user in

the BOMP Setup application. The field can be used for any purpose the

user desires.

This field is not displayed

if the user-defined field in BOMP Setup is blank.

|

|

F6 = Reference Designator

|

3 lines of 60 alphanumeric

characters each.

This field can be used to

show a routing of a component item. It will be printed on work orders and

may be printed on several reports.

|

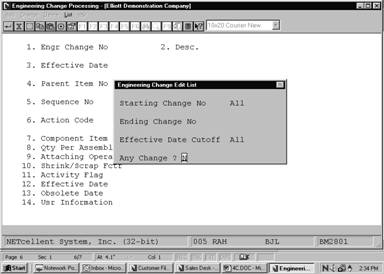

Engineering Change Edit List

|

Name

|

Type

and Description

|

|

Starting Change No

|

6 numeric digits.

Enter the starting

engineering change number for the range of engineering changes to be

printed. Defaults to All.

|

|

Ending Change No

|

6 numeric digits.

Enter the ending engineer

change number for the range of engineering changes to be printed. Defaults

to the starting engineering change number.

|

|

Effective Date Cutoff

|

A date in the standard date

format.

Enter the cutoff date for

the range of engineering changes to be printed. Only engineering changes

with effective dates on or before the date entered will be printed. Defaults

to All.

|

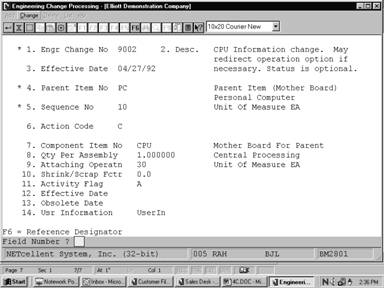

Screens

Engineering Change

Processing

Sequence Number Selection

E N G I N E E R I N G C H A N G E E D I T L I S T

Ranges:

All Changes

All Dates Printed

Change

No Change Description Parent Item Parent

Description Effective Date

9002 CPU Information change. May PC Parent Item (Mother

Board) 04/27/92

redirect operation option if Personal Computer

necessary. Status is optional.

Seq

Action Component Item Qty Per Um Component Description Llc Attch

Scrap Act Stk Ctl P/M Eff Date

10

C CPU 1.000000 EA Mother Board For Parent 1 30

.0 A Y Y M 00/00/00

Central Processing

CPU 386 operation position 30. Maintain inspection status

for sub‑assembly CPU. Operation position is portable as

needed. Inspection operation may need additional queue.

1

Changes Printed