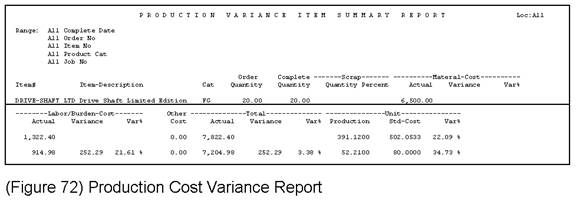

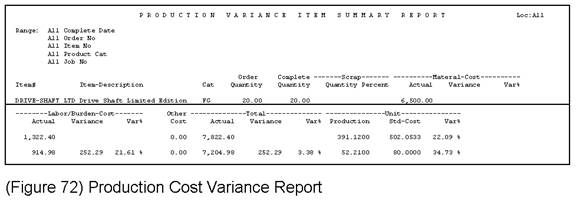

The Production Cost Variance

Report prints the cost variance between planned cost and actual production cost

for selected items. Planned production cost is calculated based on the routing

for each work order, while the actual production cost is gathered through

reporting. The report provides the scrap percentage for each selected item.

The report can be sorted by item,

product category, customer or job. When sorted by item, you can print a

summary or the order detail of each item. When sorted by product category, you

can print the category summary, item summary or order detail for each selected

item. If work orders were copied from COP and you want to know the production

cost variance for each customer, you can sort the report by customer. If you

use job numbers for work orders, you can print cost variance by job number.

The report only includes

completed production work orders and you can select orders by complete date,

location, work order number, parent item number, product category, customer

number and job number.

Main Menu è Distribution è Bill

of Material Processor è Reports è Production Analysis Report è Print è

Production Cost Variance Report

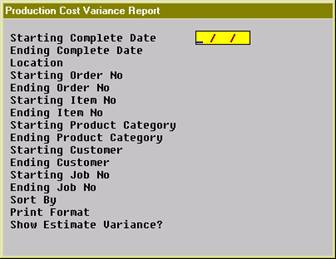

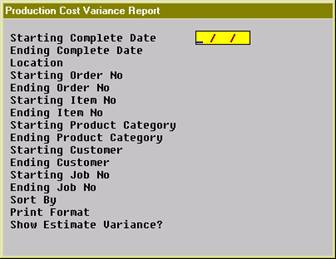

(Figure 68) Production Cost Variance Selection Screen

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

Starting Complete Date

|

Standard date format.

Enter the starting complete date for a range of production

work orders to print on the report. The complete date of a work order is the

last transaction date of the order.

Defaults to All.

|

|

Ending Complete Date

|

Standard date format.

Enter the ending complete date for a range of

production work orders to print on the report.

Defaults to the starting

complete date.

|

|

Location

|

2 alphanumeric characters.

Enter the location for a range of production work

orders to print on the report. This field supports a wild card format.

Defaults to All.

|

|

Starting Order No

|

6 numeric digits

Enter the starting order number for a range of

production work orders to print on the report.

Defaults to All.

|

|

Ending Order No

|

6 numeric digits.

Enter the ending order number for a range of production

work orders to print on the report.

Defaults to the starting

order number.

|

|

Starting Item No

|

15 alphanumeric characters.

Enter the starting product number for a range of

production work orders to print on the report.

Defaults to All.

|

|

Ending Item No

|

15 alphanumeric characters.

Enter the ending product number for a range of

production work orders to print on the report.

Defaults to the starting

item number.

|

|

Starting Product Category

|

3 alphanumeric characters.

Enter the starting product category for a range of

production work orders to print on the report. Press the F1 Key to

select products without a product category.

Defaults to All.

|

|

Ending Product Category

|

3 alphanumeric characters.

Enter the ending product category for a range of

production work orders to print on the report.

Defaults to the starting

product category.

|

|

Starting Customer

|

6 alphanumeric characters.

Enter the starting customer number for a range of

production work orders copied from COP. Press the F1 Key to select

work orders not copied from COP only.

Defaults to All.

|

|

Ending Customer

|

6 alphanumeric characters.

Enter the ending customer number for a range of

production work orders copied form COP.

Defaults to the starting

customer number.

|

|

Starting Job No

|

6 alphanumeric characters.

Enter the starting job number for a range of production

work orders to print on the report. Press the F1 Key to select work

order without a job number only.

Defaults to All.

|

|

Ending Job No

|

6 alphanumeric characters.

Enter the ending job number for a range of production work

orders to print on the report.

Defaults to the starting job

number.

|

|

Sort By

|

1 alphanumeric character.

Valid entries are:

I - By item number. The sorting

sequence is item number and order number.

P - By product category. The

sorting sequence is category, item number and order number.

C - By customer number. The sorting

sequence is customer number, category, item number and order number.

J - By job number. The sorting

sequence is job number, item number and order number.

Enter the sorting sequence for the report. Based on

the sorting sequence, you can choose different print formats.

Defaults to I.

|

|

Print Format

|

1 alphanumeric character.

Valid entries are:

S - Item/Category/Customer/Job

summary, depending on the sort sequence.

C - Category summary. Only

available when the sort sequence is C.

I - Item summary. Only available

when the sort sequence is P, C or J.

D - Order detail. Print all work

orders for selected items.

Enter the print format for the report. This determines

the detail level of the report.

Defaults to S.

|

|

Show Estimate Variance?

|

Y or N.

Enter Y to print the variance, even if the

variance is estimated. By selecting Y, the report will reveal the

variance fields available.

Defaults to N.

|

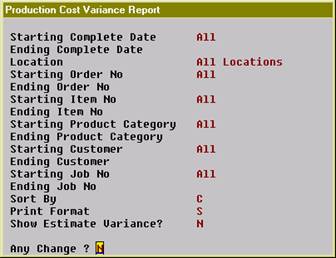

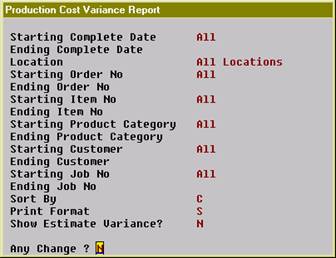

(Figure 71) Production Cost Variance Selection Screen

The Exception Report prints all

exception records. Exception records are created when the user performs

exception handling functions. These functions can be modifying time clock

data, canceling a production, reassigning a job or changing a routing.

Each exception record has a

severity level ranging from zero, for the least severe, to nine, for the most

severe, and is assigned based on the impact to the system. For example,

changing time clock data where the time has already been distributed to a

posted production transaction would create a data integrity issue and the

system will assign 9, the highest severity level, to this exception record.

Main Menu è Distribution è Bill

of Material Processor è Reports è Production Analysis Report è Print è

Exception Report

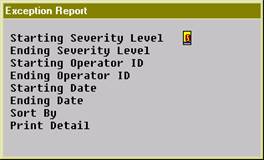

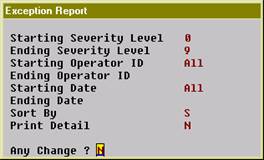

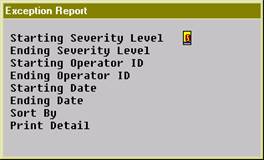

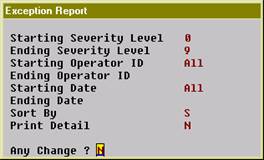

(Figure 73) Exception Report Selection Screen

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

Starting Severity Level

|

1 numeric digit.

Enter the starting severity level for a range of

exception records to print. The range can be from 0 to 9. Zero is the least

severe and nine is the most severe.

Defaults to 0.

|

|

Ending Severity Level

|

1 numeric digit.

Enter the ending severity level for a range of

exception records to print. The range can be from 0 to 9. Zero is the least

severe and nine is the most severe.

Defaults to 9.

|

|

Starting Operator ID

|

10 alphanumeric characters.

Enter the starting operator ID for a range of

exceptions for the selected operators. Press the F1 Key to select

exceptions not assigned to an operator.

Defaults to All.

|

|

Ending Operator ID

|

10 alphanumeric characters.

Enter the ending operator ID for a range of exceptions

for the selected operators.

Defaults to the starting

operator ID.

|

|

Starting Date

|

Standard date format

(MM/DD/YY).

Enter the starting date when the exceptions occurred.

Defaults to All.

|

|

Ending Date

|

Standard date format

(MM/DD/YY).

Enter the ending date when the exceptions occurred.

Defaults to the starting

date.

|

|

Sort By

|

1 alphanumeric character.

Valid entries are:

S - Sort by severity level

T - Sort by time

Enter the sort method for the report.

Defaults to S.

|

|

Print Detail

|

Y or N.

Enter Y to print additional details for each

exception record.

Defaults to N.

|

(Figure 74) Exception Report Selection Screen

|

E X C E P T I O N R E P O R T B Y C R E A T E T I M E

Ranges:

Severity 0 Thru 9

All Operators

All Dates

Level

Exception-Time Subject Reporter Override Filename

Reference-No Exception-No

0 08/17/10 11:51 Force Logoff FRANK FRANK

SYTIMCLK 000000079 000000081

08/24/10 16:52 Change Production Detail SAM FRANK BMPRDHDR

000000070 000000096

5 05/25/10 13:22 Reassign Production SAM FRANK

BMPRDHDR 000000059 000000039

6 09/02/10 17:33 Remove Time Clock SAM CHRIS

SYTIMDTL 000000015 000000121

7 09/01/10 13:08 Cancel Activity SAM FRANK

BMACTHDR 000000064 000000106

8 09/15/10 16:22 Remove Time Clock SAM WILL SYTIMDTL

000000062 000000218

Total 6 Exceptions Printed

|

(Figure 75) Exception Report Selection Screen