|

Name

|

Type

and Description

|

|

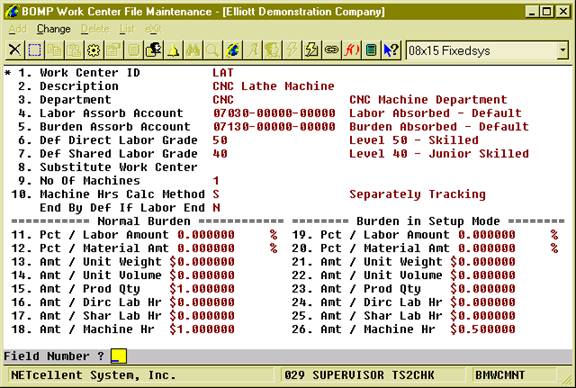

1. Work Center ID

|

6

alpha-numeric characters.

Work

Center ID.

|

|

2. Description

|

30

alpha-numeric characters.

Description

of this work center.

|

|

3. Department

|

4

alpha-numeric characters. Can be blank.

Multiple

work centers can belong to one department. By assigning a department ID, it

is possible to evaluate the performance of work centers and summarize the

evaluation for the department.

If

department ID is given, most of the following fields default to values in the

department file.

|

|

4. Labor Absorb Account

|

Default

Account format.

Labor

Absorb Account for this work center. Different labor absorb accounts can be

defined for different work centers.

Defaults

to BOMP Global Setup or Department file.

|

|

5. Burden Absorb Account

|

Default

Account format.

Burden

Absorb Account for this work center. Different burden absorb accounts can be

defined for different work centers.

Defaults

to BOMP Global Setup or Department file.

|

|

6. Def Direct Labor Grade

|

2

alpha-numeric characters.

Default

labor grade for direct labor at this work center. Any operation in this work

center will default to this labor grade in the operation file.

Defaults

to BOMP Global Setup or Department file.

|

|

7. Def Shared Labor Grade

|

2

alpha-numeric characters.

Default

labor grade for shared labor at this work center. Any operation in this work

center will default to this labor grade in the operation file.

Defaults

to BOMP Global Setup or Department file.

|

|

8. Substitute Work Center

|

6

alpha-numeric characters.

The

substitute for this work center. If there is more than one similar work

center function and it is possible to change the production routing from one

to another, this field defines the substitute for this work center. The operator

can change the production to this work center in certain situations.

|

|

9. No of Machines

|

2

numeric digits.

Number

of machines in the work center. One work center can represent more than one

machine. This field indicates how many machines are in this work center and the

system will give a warning if an operator tries to report work on more machines

than the capacity.

0 -

This work center has no machines or the capacity should be bypassed.

The

default is 0.

|

|

10. Machine Hour Calculation Method

|

1

alpha-numeric character. “M”, “C” or “S”

This

field indicates how the machine is operated and so defines how the machine

hours will be collected for production at this work center.

Options

M -

All crew members are operating the same machine at one time. A Machine Hour

is equal to the hours the crew spends on it. (Machine Hours = Labor Hours)

C -

Each crew member is operating their own machine. A Machine Hour is the sum

of the hours that each member spends on it. (Machine Hours = Labor Hours

times Number Of Crew Members)

S -

There is no direct relationship between Labor Hours and Machine Hours. This

may be a situation where the machine can run independently without an

operator involved, like a Computer Numerical Controlled (CNC) Machine.

Defaults

to BOMP Global Setup or Department file.

|

|

End By Def If Labor End

|

“Y”

or “N”

This

determines the default of whether a machine will continue or be suspended

when an operator leaves it if the Machine Calculation Method is “S”. The

operator can override this during production.

Defaults

to BOMP Global Setup or Department file.

|

|

11. Pct / Labor Amount

|

10

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from percentage of Labor Amount.

|

|

12. Pct / Material Amt

|

10

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from percentage of Material Amount.

|

|

13. Amt / Unit Weight

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per unit of parent item weight.

|

|

14. Amt / Unit Volume

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per unit of parent item volume.

|

|

15. Amt / Prod Qty

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per piece processed in production.

|

|

16. Amt / Dirc Lab Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per hour of Direct Labor.

|

|

17. Amt / Shar Lab Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per hour of Shared Labor.

|

|

18. Amt / Machine Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Normal

Burden from per Machine Hour.

|

|

19. Pct / Labor Amount

|

10

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from percentage of Labor Amount.

|

|

20. Pct / Material Amt

|

10

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from percentage of Material Amount.

|

|

21. Amt / Unit Weight

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per unit of parent item weight.

|

|

22. Amt / Unit Volume

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per unit of parent item volume.

|

|

23. Amt / Prod Qty

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per piece processed in production.

|

|

24. Amt / Dirc Lab Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per hour of Direct Labor.

|

|

25. Amt / Shar Lab Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per hour of Shared Labor.

|

|

26. Amt / Machine Hr

|

12

numeric digits with 6 decimal places and an optional minus sign.

Burden

in Setup Mode from per Machine Hour.

|

These parameters allow the

operator to configure burden driven by different reasons, either when a machine

is operating normally or when a machine is in setup mode. There are two sets

of burden parameters for each work center, one for the machine in setup mode

and another for normal mode.

Setting these parameters to

accurate values requires experience. However, a quick suggestion is to compare

the overhead amount each month with information accessible at the time, like

the labor dollar amount of that month, labor hours or machine hours. They

initially can be reasonable estimates and tuned over time to provide a better

estimate for production burden cost.

Based on figure 14, in normal

mode, each processed parent item would cost $1 and each machine hour used to

produce it will cost $1. So if 10 pieces were produced and the process time at

this work center was 2 hours, the burden cost would be $12 ($1 x 10 + $1 x 2).