After production has started and

before work orders are closed, the WIP Account may contain an amount. This WIP

Report will print all unfinished work orders and their WIP amount.

The summary format prints one

line per work order and the detail format prints the WIP amount at the

operation level for each work order. You can print the outside WIP amount, the

inside WIP amount or both.

Parts sent outside the company

for processing will distribute to the outside WIP amount. This report can

separate outside and inside WIP amounts. The system calculates outside pieces

based on unfinished productions with outside process operations. Unfinished

productions have been started, but not yet reported. They are also called Open

Productions in WO+.

The WIP Report supports both

Legacy Work Orders and Plus Work Orders. Material Work Orders are excluded

because they have no WIP.

Printing a legacy work order in

detail format will list all components of a selected work order. The component

WIP amount total may vary from the actual WIP amount of the order since the WIP

amount of a component is based on current unit cost. The unit cost can vary

from when the WIP amount occurs. This can happen if Average or Last Cost is

used as the Inventory Cost Method, or if Standard Cost is used and the standard

cost of the component is changed.

Main Menu è Distribution è Bill

of Material Processor è Reports è Work in Process Report è Print è

WIP Report

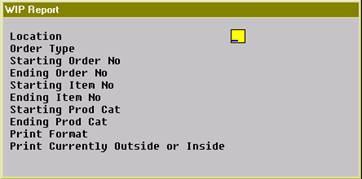

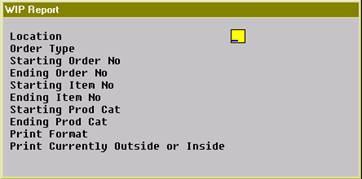

(Figure 58) WIP Detail Report Entry Screen

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

Location

|

2 alphanumeric characters.

Enter the location of work orders to print on the

report. The field supports a wildcard format.

Defaults to All.

|

|

Order Type

|

1 alphanumeric character.

Valid entries are:

Space - All

O - Legacy Work Order only

P - Plus Work Order only

Enter the type of work order to print on the report.

Defaults to All.

|

|

Starting Order No

|

6 numeric digits.

Enter the starting order number of a range of orders to

print on the report.

Defaults to All.

|

|

Ending Order No

|

6 numeric digits

Enter the ending order number of a range of orders to

print on the report.

Defaults to the starting

order number.

|

|

Starting Item No

|

15 alphanumeric characters

Enter the starting item number of a range of parent

items to print on the report. Press the F7 Key to search for an item

by item number. Press the F8 Key to search for an item by

description.

Defaults to All.

|

|

Ending Item No

|

15 alphanumeric characters.

Enter the ending item number of a range of parent items

to print on the report. Press the F7 Key to search for an item by

item number. Press the F8 Key to search for an item by description.

Defaults to the starting

item number.

|

|

Starting Prod Cat

|

3 alphanumeric characters.

Enter the starting product category of a range of

parent items to print on the report. Press the F7 Key to search for a

product category.

Defaults to All.

|

|

Ending Prod Cat

|

3 alphanumeric characters.

Enter the ending production category of a range of

parent items to print on the report. Press the F7 Key to search for a

product category.

Defaults to the starting

product category.

|

|

Print Format

|

1 alphanumeric character.

Valid entries are:

D - Detail format. Includes routing

and components.

S - Summary format. One order per

line.

Enter the format you want to print for the report.

Defaults to S.

|

|

Print Currently Outside or

Inside

|

1 alphanumeric character.

Valid entries are:

B - Both Outside and Inside WIP.

S - Print Outside and Inside WIP

separately. Only available if Print Format is S.

O - Outside WIP only.

I - Inside WIP only.

Enter the WIP amount type to print.

Defaults to B.

|

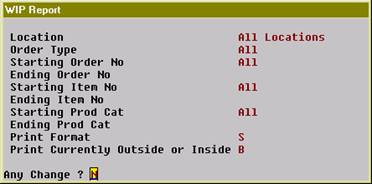

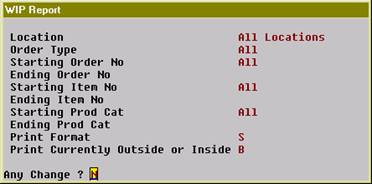

(Figure 59) WIP Detail Report Entry Screen

|

W I P S U M M A R Y R E P O R

T Loc: All

Range:

All Orders

All Items

All Product Categories

Order#

Lc Item-No Item-Description Complete-Qty Start@

Age Outstanding Mtrl-WIP Dir-Lab-WIP Shr-Lab-WIP Burden-WIP Other-WIP

Total-WIP

Scrap-Qty Qty

O000109

LA PC-386 386 Personal Computer .00

09/20/10 8 1.00

997.65 997.65

Customize During Order Entry

O000129

LA FLANGE Flange w/ 6 holes .00

09/20/10 8 1.00

212.00 212.00

P200064

LA DRIVE-SHAFT Universal Joint Drive Shaft .00 09/13/10

15 10.00 3,994.20 129.64 0.00 4.28 0.00

4,128.12

P200071

LA FLANGE Flange w/ 6 holes .00

09/22/10 6 2.00 472.00 40.00 0.00 0.42 0.00

512.42

Grand Total: 14.00 5,675.85

169.64 0.00 4.70 0.00 5,850.19

4 Orders Printed

|

(Figure 60) WIP Detail Report

The WIP Variance Report prints

out the WIP Variance Amount, Standard Cost Variance Amount and Scrap Amount for

each production transaction. The transactions are posted through the Post Production

Transactions program to create these variance amounts.

During the production,

Work-In-Process amounts may accumulate due to material, labor, burden or

outside process costs put into a work order. Once the work order is complete,

the WIP amount becomes the production cost of the parent item. The system will

create G/L distributions for both the WIP Account and the Finished Goods

Account. If the system is unable to distribute the amount left in the WIP

Account to the Finished Goods Account, WIP Variance amount occurs.

These situations occur when:

- Reporting zero quantity in the

last operation to complete a Plus Work Order that contains a WIP amount

will distribute the amount to the WIP Variance Account.

- If a Plus Work Order is a

disassembly order, where the order quantity is negative, the production

cost not related to material is distributed to the WIP Variance Account

instead of the Finished Goods Account or the Inventory Account of the

component. The variance between the sum of the material cost and parent

item cost is distributed to the WIP Variance Account as well, instead of

Standard Cost Variance Account.

Only Legacy and Plus Work Orders

can have a WIP Variance Amount.

Standard Cost Variance

amount may be present if Standard Cost is used as the Inventory Cost Method.

Legacy, Material and Plus Work Orders will have this amount when the production

cost differs from the standard cost.

Scrap amount will be

present only for Plus Work Orders. This feature needs to be set by changing

BOMP Global Setup field 44, Report Scrap to a Separate Account, to “Y” and set

a valid scrap account in field 45, WO+ Scrap Account. Any piece scrapped

during production will have the production cost distribute to the Scrap

Account. The system only calculates a scrap amount when posting a transaction

for the last operation, therefore you will only find a scrap amount in the Y

Count Point transaction.

If a production transaction

creates G/L distribution records for any variance account, the amount will be

stored in transaction history and will be printed on this report if selected.

The report can select transaction history records by a range of transaction

dates, locations, order numbers, parent item numbers and product categories.

Main Menu è Distribution è Bill

of Material Processor è Reports è Work in Process Report è Print è

WIP Variance Report

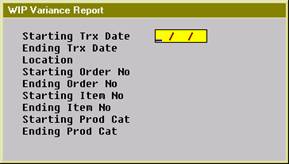

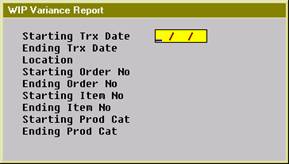

(Figure 61) WIP Variance Report Entry Screen

Entry Field Descriptions

|

Name

|

Type

and Description

|

|

Starting Trx Date

|

A standard date format.

Enter the starting date of a range of transactions to

print.

Defaults to All.

|

|

Ending Trx Date

|

A standard date format.

Enter the ending date of a range of transactions to

print.

Defaults to the starting

date.

|

|

Location

|

2 alphanumeric characters.

Enter the location of work orders to print on the

report. The field supports a wildcard format.

Defaults to All.

|

|

Starting Order No

|

6 numeric digits.

Enter the starting order number of a range of orders to

print on the report.

Defaults to All.

|

|

Ending Order No

|

6 numeric digits

Enter the ending order number of a range of orders to

print on the report.

Defaults to the starting

order number.

|

|

Starting Item No

|

15 alphanumeric characters

Enter the starting item number of a range of parent

items to print on the report. Press the F7 Key to search for an item

by item number. Press the F8 Key to search for an item by

description.

Defaults to All.

|

|

Ending Item No

|

15 alphanumeric characters.

Enter the ending item number of a range of parent items

to print on the report. Press the F7 Key to search for an item by

item number. Press the F8 Key to search for an item by description.

Defaults to the starting

item number.

|

|

Starting Prod Cat

|

3 alphanumeric characters.

Enter the starting product category of a range of

parent items to print on the report. Press the F7 Key to search for a

product category.

Defaults to All.

|

|

Ending Prod Cat

|

3 alphanumeric characters.

Enter the ending production category of a range of

parent items to print on the report. Press the F7 Key to search for a

product category.

Defaults to the starting

product category.

|

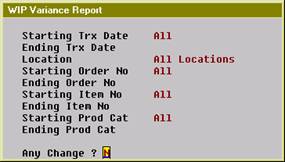

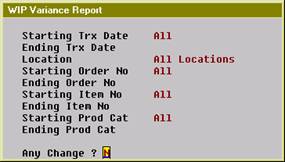

(Figure 62) WIP Variance Report Entry Screen

|

W O R K I N P R O C E S S V A R I A C E R E P O R

T Loc: All

Ranges:

All Dates

Range:

All Orders

All Items

All Product Categories

Order#

Lc Item-No Qty-Ordered Opr# T ID WC Dept Qty-Complete

Prd-Unt-Cst Mtrl-Amnt WIP-Variance WIP-Var/Qty

TRX-Date Description Description

Qty-Scrapped Std-Unt-Cst Labor-Amnt Std-Cost-Var SCV/Qty

CP

Job-No Scrap-%

Burden-Amnt Scrap-Amnt

Other-Amnt

O000131

LA FLANGE 2.00

1.00 80.0000

09/28/10 Flange w/ 6

holes

80.0000 172.00 172.0000

M100005

LA DRIVE-SHAFT 10.00 2.00

414.6500

02/23/10 Universal Joint Drive

Shaft

414.6500 189.30- 94.6500-

P200026

LA FLANGE 10.00- 0010 M PRE WHS GEN

5.00- 0.00 20.01 4.0020-

04/08/10 Flange w/ 6 holes Material Preparation

.00 20.00

.01

P200040

LA FLANGE 10.00 0030 P MIL MIL CNC

7.00 60.1814 0.00

05/11/10 Flange w/ 6 holes Milling

3.00 7.5400 0.14 368.49 52.6414

Y 30.00

% 10.01

P200042

LA FLANGE 10.00 0030 P MIL MIL CNC

.00 0.0000 0.00 2.10

05/11/10 Flange w/ 6 holes Milling

.00 7.5400 0.00

Y

.00

Grand WIP Variance: 22.11

Grand

Std Cost Var: 351.19

5 Transactions Printed

|

(Figure 63) WIP Variance Report