Any

inventory system, whether it is manual or computerized, must have some way of

recording what parts are in inventory, and in what quantity. In fact, this

record of what is in inventory is the most fundamental and necessary portion of

the Elliott's manufacturing system as well.

Because

of this, several of the basic concepts of Inventory Management will be

covered here.

Some

of these concepts are not fully implemented within the Inventory Management

package, but extend to the other packages. For example, allocation of material

is not done by any automatic process within I/M. Instead, this

allocation will be done from the Customer Order Processing, Bill Of

Material Processor or Shop Floor Control package. Many of the data

fields entered by way of Item File Maintenance are not used at all in

the Inventory Management package, but are present so that the data will

be available for one or more of the other packages, which use the Inventory

Item File.

This

discussion of the Item File will be broken down into sections dealing with

these subjects:

1. Part Numbering

2. Allocation and Deallocation of Stock

3. Inventory Location Control

4. Forecasting

5. Safety Stock

6. ABC Analysis

7. Stocked vs Non‑Stocked, Controlled

vs Non‑Controlled Items

8. Physical Inventory and Cycle Counting

9. Default Item (For quick entry of new

inventory items)

10. Item Notes

11. Interaction with other Packages

Part Numbering

The

classical definition of a part is, anything which is unique in form,

fit, or function. And if something is different in either form, fit, or

function, it should have a unique part number. However, it is beneficial to a

company to keep the number of its part numbers as low as possible. It is

estimated that it costs a company between $2,000 and $3,000 for every part

number it has on file. This includes the cost of any engineering drawings for

the part, and for someone to manage the part on an on‑going basis. So it

can be beneficial to give some thought to how you assign part numbers.

There

are many different part-numbering schemes possible. In fact, there are

probably as many different ways to define part numbers, as there are

companies. The two main types of schemes that are in use involve either

significant or non‑significant part numbers.

A

significant part number is one which describes (at least partially) what the

part is, such as a part number made up of the Product code, a couple of digits

given to describing the size of the part, a couple more characters which

describe the material the part is made of, etc. Significant part numbers have

been widely used in manual systems wherein the data entry operator and the

warehouse did not have a description of the part handy with every order or

packing slip and could recognize what part was being addressed just by looking

at the part number. Because they serve this purpose so well, significant part

numbers can be quite helpful.

The

major disadvantage to the use of significant part numbers is that after a

period of time, so many variations of a part may come into use, or so many new

parts may be added to existing product categories, that the system gets too

complicated and cannot possibly cope with all the possible variations. In this

case, it may be better to use non‑significant part numbers.

In

a non‑significant part numbering scheme, part numbers may be assigned

fairly arbitrarily, and without reference to product class, size, etc. This

may be the best scheme on a computer system, since the description of the part

is available to the operator for verification as soon as the part number is

entered. And non‑significant part numbers certainly afford a good deal

more flexibility than significant part numbers.

One compromise that is often used between these

systems is to use a partially significant system, where only the first few

characters of the part number are significant. Large distributors may find it

desirable to simply assign parts which they market the same part numbers as

their manufacturers have assigned to the part. But they cannot be sure that

the different manufacturers will assign unique part numbers. So the first few

characters of the part number may refer to the manufacturer, and the remainder

of the characters can be the manufacturer's part number.

Allocation And Deallocation Of Stock

The

Inventory Management package allows you to keep track not only of the

quantity on‑hand of each inventory item, but also of the quantity of the

item which has been allocated to already existing customer or shop orders.

There is a quantity allocated field in the Inventory Item record, as

well as a quantity on‑hand field.

This

allows you a great deal more ability to control your inventory, since you will

be able to accurately determine what quantity of the item is actually available

for use. Your prediction of requirements for the item will be more accurate

than if you were basing it solely on the quantity on‑hand.

When

a customer order is received for an item in the Customer Order Processing

package, the material required to fill the order is allocated. This

shows that the portion of the quantity on‑hand is spoken for, and should

not be used for future orders. This allocation of the material does not affect

in any way the actual quantity of the items that is on‑hand.

When

a feature/option is entered in Customer Order Processing, the parent and

all components are allocated. In Bill Of Materials Processor, the

feature is put on order. When it is produced, the quantity on hand increases

and all components quantity on hand and quantities allocated are decreased. In

Customer Order Processing, when the order is posted, the parent quantity

on hand and quantity allocated are decreased.

When

a stocked and controlled parent item is entered as a work order in Bill Of

Material Processor, the components are allocated. When it is produced, the

quantity on hand of the parent is increased, and the quantity on hand and

quantity allocated is decreased for the components.

Then when the material is issued to fill the

order, the quantity on‑hand is reduced, and the quantity allocated

is also reduced to reflect the fact that the material is no longer spoken for.

Inventory Location Control

Elliott's Inventory Management package allows you to maintain

multiple stocking locations for each inventory item, along with quantity on‑hand

and quantity allocated figures for each location. Thus you can obtain reports,

which allow you to predict usage at each location.

The

maintenance of the on‑hand and allocation figures for other than the main

stocking location is done by way of the Inventory Location File Maintenance

application.

When

a customer order is received and entered into the computer, you specify which

location is to fill the order. The on‑hand and allocation figures for

that location are then updated to reflect the activity.

In

the Item File Maintenance application, you will specify what the

manufacturing or default location for the item is; the quantity on‑hand

and allocated figures, which you will enter, refer to this manufacturing or default

location.

Forecasting

Forecasting

accurately how much of an item you are going to need at some point in the

future can be very important to a company's profits. If the forecast for an

item is too high, too much of it may be produced and then have to be kept in

inventory until it is consumed. This ties up capital in the inventory

investment, and costs you further money in carrying costs. But if the forecast

turns out to be too low, and customer demand exceeds the amount of the item you

have produced, you can again lose money.

No

one, so far, has come up with a sure‑fire technique for forecasting

inventory usage. Some of the techniques which have been developed are almost

beyond the grasp of most college graduates (unless they majored in math), and

these very sophisticated systems of prediction usually require more accuracy in

the data input to them than can be easily obtained.

Elliott's Inventory

Management package uses an easy to understand method of forecasting the

next period's usage of an item based on the item's selling history. The

technique has the rather scientific sounding name of exponential smoothing,

but is basically pretty simple. It uses a weighted moving average to calculate

next period's expected usage level for an item. Let us take a few examples to

illustrate how this calculation works. We will assume that the forecasting

period is a month. This first example will use six month's worth of sales

history.

Figure 1

65 50 55 70 50 40 Average

Usage = 333 = 55

6

Figure 2

50 55 70 50 40 155 Average

Usage = 420 = 70

6

In

Figure 1, we have a diagram showing the usage of an item for six prior months.

The average usage for these six months is 55. Then in Figure 2, we have

dropped the usage for month number 1, and added the usage for the current

month, month number 7, to the end, and recalculated a new average usage for the

item. This new average usage is our forecast for next month. As you can see,

the suddenly higher usage in month 7 caused the average usage to increase quite

a bit over the previous average usage.

Here

is another example of this technique using a longer period of sales history, 12

months.

Figure 3

65 50 55 70 50

40 35 60 70 50 65 50

Average

Usage = 660 = 55

12

Figure 4

50 55 70 50 40

35 60 70 50 65 50 155

Average

Usage = 750 = 63

12

In

Figure 3, we have 12 months of sales history, again with an average usage of

55. In Figure 4, the usage for month 1 has been dropped, and the usage for the

month just ended has been added. Even though the usage for the most recent

month jumped to 155, as in the previous example, the new average usage is only

63. As you use a longer period of sales history, a sudden increase or decrease

in any one month will be dampened more than it is dampened when you only use a

few months of history. In other words, the new forecast is more responsive to

sudden increases and decreases in usage when only a few months of history are

used, whereas, a more stable forecast which does not fluctuate as much is

obtained by using a longer period of sales history.

As

it turns out, you do not actually have to have this sales history available to

the program in order to do this calculation of the new forecast. All you have

to do is specify how much weight to place on the usage figures for the

prior period. This can be done using this table.

Periods

of Usage Weighing

Sales

History Factor

3 .50

6 .29

9 .20

12 .15

18 .11

As

you can see from this table, as you use a larger number of periods in sales

history, the importance placed on this period's usage decreases.

You

specify the usage-weighing factor for each inventory item as part of

Item File.

For

high volume items whose sales can be very volatile, you may want to use a short

period of sales history, so that new forecasts are very responsive to the

current demand for the product. For other items, you may want to use a long

sales history period, so that forecasts do not fluctuate as much as sales

fluctuate.

This

new forecast is calculated whenever you run the Recalculate Reorder Fields

application. Further detail on the actual calculations can be found in the Recalculate

Reorder Fields section of this manual.

Safety Stock

Safety

Stock is the quantity of an item to be kept on‑hand in case of sudden

demand. It serves to cushion your inventory against increases beyond your

ability to meet an unanticipated demand for the item. Initially, you should

decide how much safety stock you should keep on hand for each item. Later on,

each time you run the Recalculate Reorder Fields application, the

optimum value of the Safety Stock field will be recalculated.

This

calculation is based on how far the forecast is deviating from the actual

usage. If the forecast is consistently running lower than the actual usage

(i.e., usage is exceeding the forecast) the amount of safety stock to keep on‑hand

will increase.

ABC Analysis

An ABC Analysis can be a useful tool for categorizing your

inventory items. It is based on the general principle that a small percentage

(about 15‑20%) of your inventory items will be found to produce a large

percentage (about 70‑80%) of your income (Category A items), a larger

portion of your inventory items (about 30‑40%) will be found to produce

about 15‑20% of your income, and that the remaining 40‑60% of your

inventory items will account for only the remaining 5‑10% of income.

Usage in

Dollars Inventory Items Class

70‑80%

15‑20% A

15‑20%

30‑40% B

5‑10%

40‑60% C

You may find it of great benefit to tightly

control the inventory levels of the relatively few Class A items, since these account

for a higher percentage of activity and bring in a higher proportion of your

income. On the other hand, those items which are relatively low‑activity

items can be managed by a looser Inventory Management package on a more casual basis.

When

you first set up the Inventory Item File, you may not have a breakdown of these

categories available. If not, you can leave the ABC Analysis code (called the

Inventory Class code on screen 3 of the Item File) blank. Then later, after

some sales history has accumulated for your inventory items, run the Print ABC Analysis Report application. After the report has been run, and

you are satisfied with the results obtained, you may have the program go

through the inventory items, setting their inventory class.

Stocked vs. Non‑Stocked, Controlled vs. Non‑Controlled

There

are two fields in the Inventory Item record, which will be discussed here, the

Stocked Flag and the Controlled Flag.

The

stocked flag can have one of two values, either Y = Stocked, or N =

Non‑Stocked.

A

stocked item is one, which you plan to keep on the shelf either for sales to

customers or for use in your manufacturing plan. A non‑stocked item is

one which is never kept on the shelf as a finished end item, ready for sale or

use in the plant, even though its components may be kept on stock at all

times. A non‑stocked item may be manufactured or assembled to customer

order, and so is not kept on the shelf itself.

The

controlled flag can have one of two values, either Y = Controlled or N =

Non‑Controlled.

A

controlled item has its quantity in inventory allocated when a customer order

or shop order is issued which requires a quantity of the item, and this

quantity of the item is de‑allocated when the customer order is shipped

or the materials are issued to the shop. This allocation and de‑allocation

does not occur for a non‑controlled item.

Before

covering how these fields are used by the other Manufacturing packages, let us

take a few examples of items, which illustrate the possible combinations, which

can occur using these two fields. We will use a company, which manufactures

bicycles for the example:

1. A stocked and controlled item. This would be

an item, which is kept in stock and which is allocated when ordered, and de‑allocated

when used. An example of this would be the handlebars for the bicycle. It may

be the company's policy to always keep these handlebars in stock, ready for

issue when needed for assembly. But it is also important to know how much of

the quantity on‑hand has already been allocated to orders, which

currently exist. Thus the handlebars are a controlled item as well.

2. A stocked but non‑controlled item.

This would be an item which is always kept in inventory, but which is not

allocated or de‑allocated by the processing of orders. An example of

this might be the nuts used for holding parts of the bicycle together. These

nuts are usually made available in boxes in appropriate areas of the shop, and

they are used as needed. They are replenished when a visual review or a two‑bin

system shows that there is a need.

3. A non‑stocked but controlled item.

This item is not kept in stock for regular orders but instead is purchased or

manufactured for a particular customer order. But once it is made, it is

definitely controlled. An example of this might be a particular seat assembly

that is made for one particular customer. Once it is made, you definitely want

to have its use controlled.

4. A non‑stocked and non‑controlled

item. This might be an item, which only exists as a temporary sub‑assembly

at some point in the assembly procedure, such as a particular gear assembly.

This gear assembly might have engineering drawings associated with it, and the

company may want to be able to determine how many of them have been made, even

though the item never goes into stock and is not allocated or de‑allocated.

This type of item is often referred to as a phantom subassembly.

An

understanding of these terms can be important if you plan to use the Customer Order Processing package, or any of the other Elliott packages which use Bill of Material Processor. For example, when a customer orders a part

which is non‑stocked but controlled, and for which a Bill of Material

exists, the item itself is allocated. The program then explodes through the

Bill of Material and allocates those components, which are stocked, if the components are also controlled.

Physical Inventory And Cycle Counting

A physical inventory is the process of getting an actual count of how

many of every inventory item is currently in stock. For some companies, the

process of taking a physical inventory entails closing down the entire company

for a period of weeks, in order to obtain accurate on‑hand figures.

A

good way to keep these figures accurate without doing many physical inventories

is to institute a cycle counting program. In cycle counting, the inventory is

being counted on a constant, cyclical basis. For example, a certain number of

inventory items might be counted today, and their on‑hand values updated

in the Inventory Item File. The other set of items would be counted tomorrow,

etc. You might decide to count items which have been classed as Category A

items on a more frequent basis than Category B or C items, and thus to keep

their on‑hand values as current as possible.

Many

accountants, in preparation for producing a company's financial statements,

insist that a full physical inventory be done. But it is quite possible that

if you can demonstrate a high degree of accuracy in a selected sample of items

kept current by way of an on‑going cycle counting system, the accountant

might waive the physical inventory requirements, and accept the computer's

record of inventory value on‑hand.

Default Item

To

expedite entry of initial inventory a default item may be loaded to determine

default field values. A function key will prompt you after the basic

information on the item has been entered to accept the remaining fields as

defined in the default item. To utilize this option an item must be entered

with an item number of Default‑Item.

The Default‑Item is treated by the system as a regular inventory

item. It should therefore be deleted after the initial inventory has been

loaded. It is created the same as any other item using the Add function of this application.

Use

of the Default‑Item allows the user to completely bypass the entry of

the second and third screens of the Item File. If the system finds this item

on file, it will prompt the user with a function key option to default

remaining fields during entry of the new item. The function key prompt appears

during two field entries on the first screen of item entry. These field

entries include the Product Category entry and the Backorderable question.

NOTE: This

applies to an item that has any stock on hand, allocated, on order, backordered

or PTD or YTD accumulators, at any location other than the Default or manufacturing location.

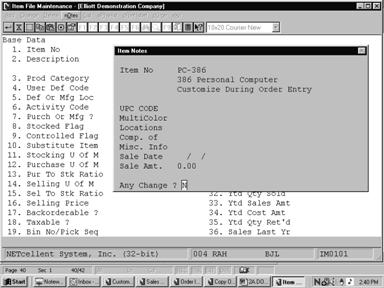

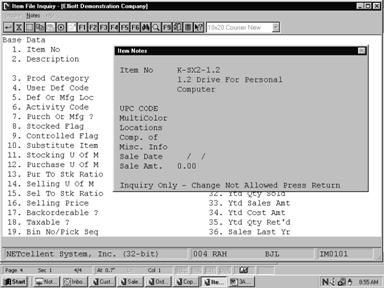

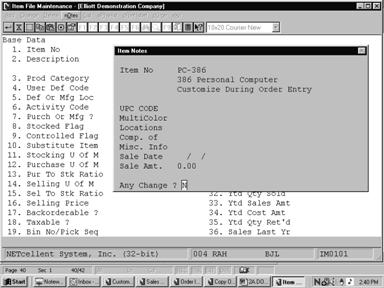

Item Notes

By

selecting Notes from the Item File Maintenance menu bar, you can define any additional requirements for each item

record on file. The benefit of this feature is apparent when you need special

information that isn't present in any other file maintenance application. The Notes function displays a window that enables entry of

the item's number. You can enter up to 5 lines 30 characters each of

additional comments plus one date and one amount field. This option must be

setup in the I/M

Setup application from the Util_setup pull down window.

In

fact, most of the fields in the Inventory Item record are

not used directly by the Inventory Management

package. They are present so that the I/M package

can interact with the other manufacturing packages. Those packages which draw

heavily on the Inventory Item File will be Customer Order Processing, Bill of Material

Processor, Purchase Order and Receiving, Material Requirements Planning and

Master Scheduling.

If

you do not plan to implement all of these packages at once, you will not be

forced to enter data for every field in the Inventory Item File. As you put

into use each subsequent package, you could then go back and fill in the data

that is needed.

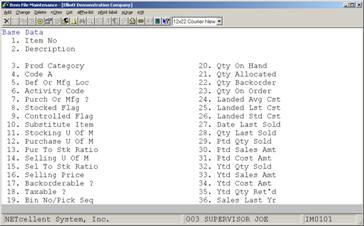

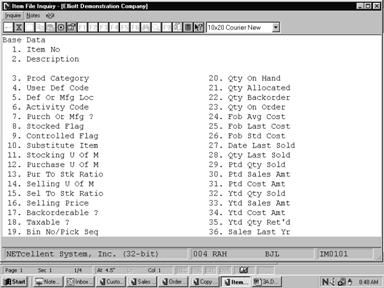

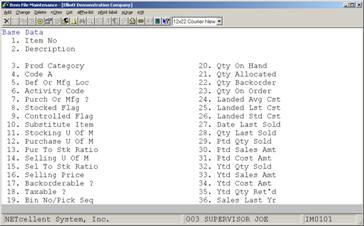

Select Item File from the pull down I/M

Maintenance window. The following screen will then be displayed:

The following options are available:

* Select the desired mode

from the Item File menu bar

* Enter the data requested

on the screen

To return to the menu bar, press the ESC

or F10 key. To leave this application, press X for EXIT

when positioned at the menu bar.

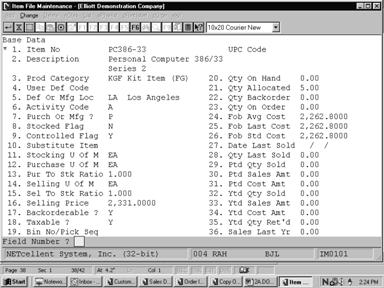

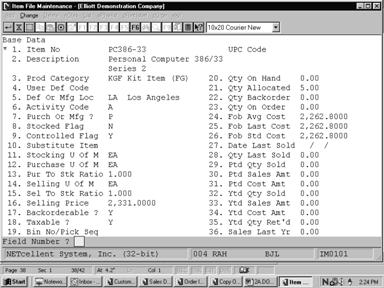

Entry Field Descriptions

Base Data - First Screen

|

Name

|

Type

and Description

|

|

1. Item No

|

15 alphanumeric characters.

Enter

the item number, which will be used to identify the item. This item number

can contain alphanumeric characters, and/or numeric digits, depending on how

you wish to utilize it.

Enter an item number of Default‑Item that

can be used as a temporary default loading item. If this item is a valid

item on file, the system will prompt you to press a function key to default

the rest of the fields of the new item being entered to those of the default

item. Using this feature will substantially reduce initial item loading time

for new items. After the Item File has been loaded, the default item should

be deleted.

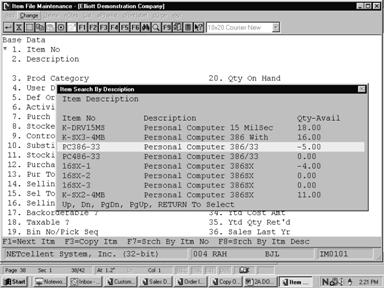

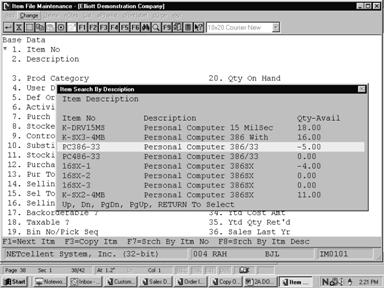

In change or delete mode,

pressing the F7 key here will allow you to search by item number or

pressing the F8 key here will allow you to search by item description.

|

|

2. Description

|

Two lines of 30 alphanumeric

characters each.

Enter the description of the item.

In many applications, the

programs allow you to look up an item by way of entering some portion of its

description, instead of the item number. For this reason, you should enter

the description with the most meaningful portion of the description first.

For example, it would be better to enter 50 gallons of white paint as paint,

white, 50 gallons so that the operator could enter paint, white

and have the program find every item whose description begins with those

characters. This will also cause similar items to print together in the

Alphabetical Inventory Item List.

|

|

3. Prod Category

|

3 alphanumeric characters.

Enter the item's product category. It is up to you to

define the Product Category codes in Product Category File Maintenance

application.

If the default item has been

entered, press the F1 key to default the rest of the non‑entered

fields of the item to those of the default item.

|

|

Prod Category (continued)

|

If an entry is made here it

will be validated against the Product Category File.

Press the F7 key to

search for product category.

|

|

4. User Def Code

|

2 alphanumeric characters.

You can utilize this code

for any purpose you choose. It is not used currently in any of the programs

either in Inventory Management or in the other manufacturing packages.

|

|

5. Def Or Mfg Loc

|

2 alphanumeric characters.

Enter the two‑character code, which designates

the location where the item is manufactured, or the default stocking

location.

In change mode, you will not be allowed to change this

to a location, which is already on file for this item in the Inventory

Location File.

Press the F7 key to search for location.

Defaults to location defined

in I/M Setup.

|

|

6. Activity Code

|

1 alphanumeric character.

This field can have one of these values:

A = Active

F = Forecasted

O = Obsolete

P = Planning

An active item is one currently in use, or being sold

to customers. A forecasted item is one, which is forecasted to be active in

the near future. An obsolete item is one, which is no longer a standard

part, though there may still be a supply of the item on‑hand, which can

be sold or used in manufacturing processes. A planning item allows you to

enter forecasted product lines for analysis purposes. In the Inventory

Management package, this is mainly an informational field, although it is

used in other of the manufacturing packages.

The field defaults to A,

or Active.

|

|

7. Purch Or Mfg ?

|

1 alphanumeric character.

This field designates whether the item is purchased or

manufactured.

P = Purchased

M = Manufactured

I = Spare

Parts

An I entered here will only be used by Elliott's

Operator 10 Maintenance Management software package.

The default is P, or

Purchased.

|

|

8. Stocked Flag

|

Y or N.

If an item is stocked, the user plans to keep it on the

shelf, in ready‑to‑use form, either for sales to customers or for

use in the manufacturing facility.

If an item is not stocked, it is never kept on the

shelf, although its components may be stocked. The item is manufactured or

assembled to customer order, or when needed during the manufacturing process,

and so is not kept on the shelf itself.

The default is Y.

|

|

9. Controlled Flag

|

Y or N.

If an item is controlled, it is allocated when customer

or shop orders are issued for it and deallocated when the order is shipped or

the materials are issued to the shop. This allocation and deallocation does

not occur for a non‑controlled item.

The default is Y.

|

|

10. Substitute Item

|

15 alphanumeric characters.

Enter the substitute item for the item. In Customer

Order Processing, if substitute items are allowed then a function key can

be pressed to use the substitute item. If the substitute item is out of

stock or not acceptable then the function key may be pressed again to use

this item's substitute item. Using this linked method, multiple substitute

items may be looked up.

Press the F7 key to

search by item number, or the F8 key to search by item description.

|

|

11. Stocking U Of M

|

2 alphanumeric characters.

This is the unit of measure when stocking the item.

Some examples of this might be each, gallon, case, etc.

Default is EA, or

each.

|

|

12. Purchased U Of M

|

2 alphanumeric characters.

This is the unit of measure

in which the item is purchased from its vendor. This may be different from

the unit of measure in which you sell the item to your customers. This field

defaults to the stocking unit of measure.

|

|

13. Pur To Stk Ratio

|

7 numeric digits with 3

decimal places (9,999.999).

This is the ratio between

the purchase unit of measure and the unit of measure you use for stocking the

item. For example, you may purchase the item by the case, and each case may

contain 50 of the item. But you may want to keep a record of how many units

of the item are on‑hand, rather than how many cases are on‑hand.

In this case, the purchase to inventory ratio would be 50. This field

defaults to 1.000.

|

|

14. Selling U Of M

|

2 alphanumeric characters.

This is the unit of measure

when selling the item. Some examples of this might be each, gallon, case,

etc. This field defaults to the stocking unit of measure.

|

|

15. Sel To Stk Ratio

|

7 numeric digits with 3

decimal places (9,999.999).

This is the ratio between

the stocking unit of measure and the selling unit of measure. An example of

this might be if the stocking UOM is each and the selling UOM is case then

the sell to stock ratio would be 24 (assuming a case contains 24). This field

defaults to 1.000.

|

|

16. Selling Price

|

10 numeric digits with 4

decimal places and an optional minus sign (999,999.9999‑).

This is the price charged

for the item. In the Customer Order Processing package, this price

may be modified by price breaks, but this is the basic price of the item.

|

|

17. Backorderable ?

|

Y or N.

This field designates whether or not the item can be

backordered.

When a customer orders the item and there is none in

inventory to fill the order, one of two conditions may be true. Either 1)

the item has been ordered and can be shipped to the customer when it arrives,

or 2) no further supplies of the item on hold until the receipt of an

additional supply is called backordering the item. If more of the

item can be ordered to meet an out of stock situation, the item is

backorderable. If no more can be obtained, the item is not backorderable.

If the default item has been

entered, press the F1 key to default the rest of the non‑entered

fields of the item to those of the default item. The default answer to this

question is Y.

|

|

18. Taxable ?

|

Y or N.

Is the item taxable or not?

The default answer to this question is Y.

|

|

19. Bin No/Pick Seq

|

8 alphanumeric characters.

This is the number of the

warehouse bin where the item is stored. When a list is prepared for the

warehouse people to use in pulling items from stock, the list is printed in

order by this picking sequence or Bin Location code.

|

|

20. Qty On Hand

|

A standard quantity format

with an optional minus sign.

This is the actual quantity of the item, which is

currently in stock.

This quantity is increased

by the recording of receivings transactions, and decreased by the filling of

customer orders for the item or by issuing a quantity of the item to the

company's manufacturing facility.

|

|

21. Qty Allocated

|

A standard quantity format

with an optional minus sign.

This is the quantity of the

item, which has already been allocated to meet customer orders or to meet the

projected needs of the manufacturing plant. When the customer orders are

actually shipped, or the plant requirements are satisfied by removing stock

from inventory, this quantity decreases by the amount removed or shipped.

|

|

22. Qty Backorder

|

A standard quantity format

with an optional minus sign.

This is the quantity of the

item, which has already been backordered to meet customer orders or to meet

the projected needs of the manufacturing plant. When the customer's

backorder is actually filled, this quantity decreases by the amount filled.

|

|

23. Qty On Order

|

A standard quantity format

with optional minus sign.

This is the quantity of the

item, which is currently on order. This quantity is increased when purchase

orders for the item are processed, and decreased when orders for the item are

received into stock.

|

|

24. Average Cost

|

10 numeric digits with 4

decimal places and an optional minus sign (999,999.9999‑).

This is the average cost per

unit of this item, which is currently in stock. This is a moving average,

which is recalculated whenever a new supply of the item is received.

|

|

25. Last Cost

|

10 numeric digits with 4

decimal places and an optional minus sign (999,999.9999‑).

This is the cost of the item

the last time it was purchased. This field is updated every time a new

supply of the item is received into stock.

|

|

26. Standard Cost

|

10 numeric digits with 4

decimal places and an optional minus sign (999,999.9999‑).

This is the standard cost of

the item. This field is not updated every time a new supply of the item is

received into stock. This field must be updated manually by the user.

|

|

27. Date Last Sold

|

A standard date format.

Defaults to the system

date. This is the last date that any of this item has been sold.

|

|

28. Qty Last Sold

|

A standard quantity

accumulator format with an optional minus sign.

This is the quantity of this

item sold on the last order.

|

|

29. Ptd Qty Sold

|

A standard quantity

accumulator format with an optional minus sign.

This is the quantity of the

item, which has been sold so far this period. This field is updated after

the invoicing of orders in the Customer Order Processing package.

|

|

30. Ptd Sales Amt

|

11 numeric digits with 2

decimal places and an optional minus sign (999,999,999.99‑).

This is the dollar amount of

sales of this item so far this period. This field is updated after the

invoicing of orders in the Customer Order Processing package.

|

|

31. Ptd Cost Amt

|

11 numeric digits with 2

decimal places and an optional minus sign (999,999,999.99‑).

This is the dollar amount of

the cost of the quantity of this item, which has been sold so far this

period. This field is updated after the invoicing of orders in the Customer

Order Processing package.

|

|

32. Ytd Qty Sold

|

A standard quantity

accumulator format with an optional minus sign.

This is the quantity of the

item, which has been sold so far this period. Refer to the above field, Qty

Sold PTD.

|

|

33. Ytd Sales Amt

|

11 numeric digits with 2

decimal places and an optional minus sign (999,999,999.99‑).

This is the dollar amount of

sales of this item so far this year.

|

|

34. Ytd Cost Amt

|

11

numeric digits with 2 decimal places and an optional minus sign

(999,999,999.99‑).

This is the dollar amount of

the cost of the quantity of this item, which has been sold so far this year.

|

|

35. Ytd Qty Ret'd

|

A standard quantity

accumulator format with an optional minus sign.

This is the quantity of the item, which has been

returned to stock this year. This field is updated after the invoicing of

orders in the Customer Order Processing package.

Several of the above fields cannot ordinarily be

changed in change mode on Item File. These fields are updated by the posting

of transactions to the Inventory Item File either from the Inventory

Management package or from one of the other manufacturing packages.

These fields are:

Qty

On‑Hand Qty Allocated

Qty

Backordered Average Cost

Price Usage

PTD

Usage

YTD Usage Last Year

Qty

Sold PTD Qty Sold YTD

Sales

PTD Sales YTD

Sales

Last Year Cost PTD

Cost

YTD Qty Ret'd YTD

If there is really a need to

change any of these fields due to some sort of posting error, press F6

when the Field Number ? question is displayed in change mode. You will then

be allowed to change these fields. This option is only valid if the Change

Protected Fields question in I/M Setup is set to Y.

|

|

36. Sales Last Yr

|

11 numeric digits with 2

decimal places and an optional minus sign (999,999,999.99‑).

This is the dollar amount of

sales of this item last year.

|

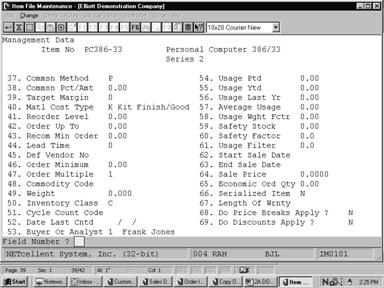

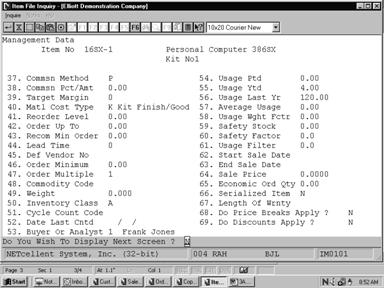

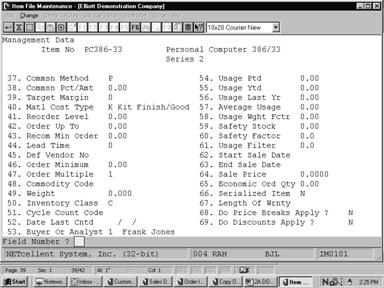

Management Data ‑ Second Screen

|

Name

|

Type

and Description

|

|

37. Commsn Method

|

1 alphabetic character.

If calculate commission type is by item in Customer

Order Processing then this field determines how the commission is

calculated for each item. The commission method must be one of the

following:

A = Amount

C = %

of Cost

M = %

of Margin

P = %

of Price

This field defaults to P.

|

|

38. Commsn Pct/Amt

|

7 digit numeric file with 2

decimal places (99,999.99).

This is the commission

percent or amount for this item. If the commission method is C, M,

or P, enter the commission percent given for this item. The commission

percent can not be greater than 100%. If the commission method is A,

enter the commission amount given for this item.

|

|

39. Target Margin

|

3 numeric digits (999).

This is the targeted profit margin for the item, calculated

by comparing the profit made by selling the item to the item's cost. For

example, if the cost of an item is $5.00 and its selling price is $8.00, the

percent of profit would be: (8 ‑ 5) / 5 = 60%. You should enter the

profit margin you wish to obtain for the item.

This field is printed on the

Sales Comparison Reports in the Customer Order Processing

package.

|

|

40. Matl Cost Type

|

1 alphanumeric character.

Enter the item's material cost type. It is up to you

to define valid material cost types using Material Cost Type File

Maintenance. This field will be used to define this item's inventory

asset account. This field defaults to the default material cost type in I/M

Setup.

Press the F7 key to

search for Material Cost Type.

|

|

41. Reorder Level

|

A standard quantity format.

When the quantity of the item on‑hand falls below

the reorder level, an order should be placed for the item.

This could be performed via the Create Unreleased

Purchase Order's By Vendor application, if you wish.

The reorder level is calculated by adding the amount of

stock you want to keep on hand for sudden emergency demands (safety stock) to

the amount of stock you expect to use during the time it takes to receive a

new supply from the vendor or from the manufacturing facility.

This reorder level is recalculated by the package

whenever the Recalculate Reorder Fields application is run.

If this field is left at

zero, it will be calculated on the first run of the Recalculate Reorder

Fields application.

|

|

42. Order Up To

|

A standard quantity format.

This is the maximum quantity

of the item that it is desirable to have in stock. This quantity would be

equal to the reorder point plus the order quantity. The order up to level is

usually used in a periodic review system in which the quantity on‑hand

is inspected visually, and if it is low, enough is ordered to bring the on‑hand

back to the order up to level.

|

|

43. Recom Min Order

|

A standard quantity format.

This is the absolute

minimum, which should be ordered at one time. It is equal to the amount of

stock that will be consumed during the time it takes to obtain new supplies

from the vendor or from the manufacturing facility. If only this amount were

ordered, you would usually find yourself having to place a new order for the item

as soon as the new supply arrived. Thus, you would normally order more than

this recommended minimum order. The amount of the recommended minimum order

is recalculated every time the Recalculate Reorder Fields application

is run. If this field is left at zero, it will be calculated on the first

run of the Recalculate Reorder Fields application.

|

|

44. Lead Time

|

3 numeric digits (999).

This is the number of calendar days, which pass between

the ordering of a new supply of the item and the actual receipt of the item

into stock.

If this field is left at

zero, the Recommended Minimum Order field will always be set to zero by the Recalculate

Reorder Fields application.

|

|

45. Def Vendor No

|

6 alphanumeric characters.

The default or main vendor from which the item is

purchased. It is important to enter a vendor number here if the I/M

Create Unreleased PO's By Vendor application will be used to

automatically generate purchase orders.

Press the F7 key to

search by vendor number or the F8 key to search by vendor name.

|

|

46. Order Minimum

|

A standard quantity format.

In many cases, there is a

minimum quantity of the item, which can be purchased from the vendor. For

example, if the item only comes in cases, at least one case must be

purchased. If a case consisted of 50 of the items, then this field would

have the value of 50.

|

|

47. Order Multiple

|

4 numeric digits (9999).

The item should be ordered in multiples of this

quantity. For example, this order multiple might be the quantity per case.

This field defaults to 1.

|

|

48. Commodity Code

|

4 alphanumeric characters.

This is a user‑defined code, which identifies a

category of items, which you purchase from some vendor. For example, you

might assign the code ST to steel products.

The Purchase Order and

Receiving package allows you to specify which vendors supply which

Commodity Codes, and provides various reports based on this Commodity Code.

|

|

49. Weight

|

8 numeric digits with 3

decimal places (99,999.999).

Enter the unit weight of the

item. This helps to determine the best method of shipping the item.

|

|

50. Inventory Class

|

1 alphanumeric character.

A, B, or C may be entered

here for the ABC Analysis code

A more detailed explanation

of the ABC Analysis concept is contained in the for Item File Maintenance.

|

|

51. Cycle Count Code

|

1 alphanumeric character.

The purpose of the cycle count code is to allow you to

print a Cycle Count Worksheet for those items with selected cycle

count codes. Only these items will be cycle counted.

You may define the cycle

count codes to be used in your inventory system in any way you choose.

|

|

52. Date Last Cntd

|

A standard date format.

This is the date a cycle

count was last done for the item.

|

|

53. Buyer Or Analyst

|

2 alphanumeric characters.

This is a user‑defined field designating who the

main buyer or analyst for the item is. Buyers or analyst codes may be defined

using the Buyer/Analyst Code File Maintenance application.

Press the F7 key to

search for Buyer/Analyst.

|

|

54. Usage Ptd

|

A standard quantity

accumulator format with an optional minus sign.

The quantity of the item,

which has been used so far this period. This usage would have come about

either as the result of shipping a quantity of the item to a customer, or by

consuming the item as a component of some manufacturing process. The field

is updated either after the invoicing of orders in the Customer Order

Processing package, by Inventory Transaction Processing, or by

producing work orders in Bill Of Material Processor.

|

|

55. Usage Ytd

|

A standard quantity

accumulator format with an optional minus sign.

The quantity of the item,

which has been used so far this year. Refer also to the above field, Usage

PTD.

|

|

56. Usage Last Yr

|

A standard quantity

accumulator format with an optional minus sign.

The quantity of the item, which

was used last year. Refer also to the above field, Usage PTD.

|

|

57. Average Usage

|

This is your projected

average usage of the item in one period. The length of the period is defined

in I/M Setup.

The value of this field is recalculated every time the Recalculate

Reorder Fields application is run, based on a comparison between the

actual usage for the previous period and the previous value of this field.

It is important that a

reasonable estimate of the average usage be entered in this field. If this

is not done, it may take several periods of recalculation before it corrects

itself. Exactly how long the self-correction will take is determined by the

usage weight factor. For example, if the usage weight factor is .29,

it will take six periods before this figure is accurate.

|

|

58. Usage Wght Fctr

|

3 numeric digits with 2

decimal places (9.99).

This is the alpha factor used in forecasting the next

period's usage of the item, based on the actual usage for the previous

period, and the forecast for that period. It determines the number of

periods of sales history to use in forecasting next period's usage. Based on

experience in the manufacturing industry, a table of alpha factors for

periods of different lengths has been drawn up for your use.

Periods

of Usage Weighing

Sales

History Factor

3 .50

6 .29

9 .20

12 .15

18 .11

|

|

Usage Wght Fctr (continued)

|

In the calculation of a new

forecast, as you use more periods of sales history, the importance placed on

the previous period's actual usage decreases. Thus a sudden change upward or

downward will not produce a widely out of line forecast for next period.

If this field is left at

zero, the forecast for the next period will never change, regardless of how

high or low the actual usage goes.

|

|

59. Safety Stock

|

A standard quantity format.

The demand for an item may vary over a period of time.

A frequently used way of ensuring that there is enough stock on hand to meet

this variable demand is to always keep a supply of extra stock. This extra

stock is called safety stock. You may enter the initial value of the safety

stock field. It will then be recalculated to reflect changes in actual usage

each time the Recalculate Reorder Fields application is run.

If this field is left at

zero, it will be calculated on the first run of the Recalculate Reorder

Fields application.

|

|

60. Safety Factor

|

2 numeric digits with 1

decimal place (9.9).

This safety factor is used in recalculating the safety

stock when the Recalculate Reorder Fields application is run. In

general, the higher the safety factor is set, the higher the safety stock

will be. Thus the number of out‑of‑stock situations will

decrease.

The following table of safety factors has been drawn up

from experience in the manufacturing industry. It is based on the customer

service level you want to maintain. For example, if you want to provide a

customer service level of 85%, meaning that 85 out of 100 times a

customer orders the item it will be in stock, you would specify the safety

factor at 1.3.

Customer Service Safety

Level Factor

50%

0.0

75%

0.8

80%

1.1

85%

1.3

90%

1.6

|

|

Safety Factor (continued)

|

Customer Service

Safety

Level Factor

95%

2.1

97%

2.4

99%

2.9

99.5%

3.2

99.8%

3.6

99.9%

3.9

99.99%

5.0

If this field is left at

zero, there will not be any safety stock, so about half the time you will be

out of stock.

|

|

61. Usage Filter

|

2 numeric digits with 1

decimal place (9.9).

The usage filter is used during the calculation of a

new forecast for the item.

If a period's actual usage is suddenly very high in

comparison with the forecast, it can cause the new forecast to appear higher

than it should be. For this reason, you may want to dampen the effect of

these sudden usage increases.

When calculating the new forecast, the usage figure

used for the calculation is never allowed to be greater than the usage filter

times the earlier forecast. For example, if the prior forecast for an item

were 1,000, this month's actual usage was 8,000 and the usage filter was 5,

the usage figure used in the calculation of the new forecast would not be

allowed to exceed 5,000 (5 x 1,000). In this example, 5,000 would be the

figure used for actual usage period to date in the calculation.

If this field is left at zero, no dampening will occur.

If it is less than one it will force the forecasted average usage to decrease

regardless of actual usage.

When initially setting up

your package, if you are not certain that the Average Usage field is

accurate, use a fairly high usage filter.

|

|

62. Start Sale Date

|

A standard date format.

When the item is on sale,

enter here the starting date of the sale, and in the next field the ending

date of the sale. If the date of the order is between these dates, the sale

price will be used for the item, instead of the regular item price. The

Price Code File Maintenance application in the Customer Order

Processing package allows you to enter additional pricing data for

inventory items.

|

|

63. End Sale Date

|

A standard date format.

Refer to the above field,

the Start Sale Date.

|

|

64. Sale Price

|

10 numeric digits with 4

decimal places and an optional minus sign (999,999.9999‑).

This sale price will be used

instead of the regular item price during the dates defined above.

|

|

65. Economic Ord Qty

|

A standard quantity format.

It may be beneficial to purchase this item in large

enough quantities that the cost of repeatedly ordering is minimized. At the

same time, you will want to keep the dollar value of inventory as low as

possible in order to minimize carrying costs. The quantity of the item to

order which best balances these factors is called the Economic Order

Quantity. This value is not calculated by the package. You should

determine, based on your experience, what this quantity should be and enter

it here.

The equation is :

Where Q is the

quantity to be ordered, A is the annual sales, S is the setup

or ordering cost r is the carrying cost rate, and v is the

item's unit cost.

|

|

66. Serialized Item

|

Y or N.

If using serialized items in I/M Setup.

Enter yes here if this item will have serial numbers.

The default answer is N.

This field cannot be changed if the quantity on order

is greater than zero.

A more detailed explanation

of serialized processing is contained in the for this application.

|

|

66. Lot Numbers ?

|

Y or N.

If using lot items in I/M Setup.

Enter yes here if this item will have either serial

numbers or lot numbers.

The default answer is N.

This field cannot be changed if the quantity on order

is greater than zero.

A more detailed explanation

of serialized or lot processing is contained in the for this application.

|

|

67. Length Of Wrnty

|

3 numeric digits (999).

This field is used for

serialized inventory only. Enter the number of days the item will be under

warranty after it has been sold.

|

|

68. Do Price Breaks Apply

?

|

Y or N.

If this flag is set to Y, and the pricing basis

(see COP Price Code File Maintenance) is D or M, the percentage

set in the price code file will be applied against the specified Item sale

price. If this flag is set to Y, and the pricing basis is P,

the straight Item sale price will be used.

If this flag is set to N, no price breaks will

be calculated.

The default answer to this

question is N.

|

|

69. Do Discounts Apply ?

|

Y or N.

During the sale, do other discounts apply?

The default answer to this

questions is N.

|

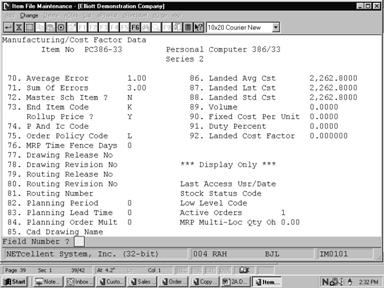

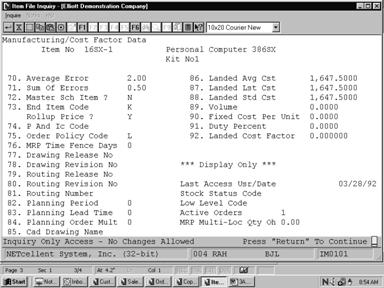

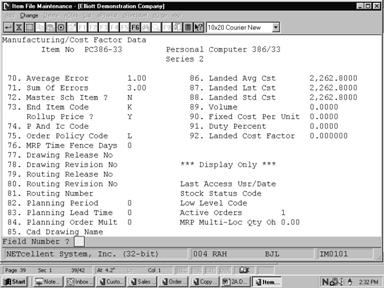

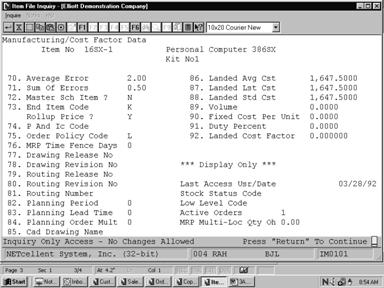

Manufacturing Data - Third Screen

This

information will only be displayed if the I/M Setup manufacturing flag

is set to Y.

|

Name

|

Type

and Description

|

|

70. Average Error

|

A standard quantity format.

This is the average deviation between the forecasted

usage of the item and its actual usage. This figure is recalculated when the

Recalculate Reorder Fields application is run, and is then used to

recalculate the new safety stock level.

Unless you have been keeping

enough forecast data to enter this figure accurately, it is best to leave the

field at zero.

|

|

71. Sum Of Errors

|

A standard quantity format

with an optional minus sign.

This field is also used

during the recalculation of reorder fields. It is equal to the sum of the

deviations between the forecasted usage for the item and its actual usage. It

is probably best not to make an entry for this figure and allow the computer

to update the field when appropriate.

|

|

72. Master Sch Item ?

|

Y or N.

If you are using the Master Scheduling package,

this field designates whether this item should be maintained in the master

production schedule.

The default is to N.

|

|

73. End Item Code

|

1 alphanumeric character.

The value of this code is user‑defined with two

exceptions.

F = Feature

Item

K = Kit

Item

Feature items may only be

used if the BOMP package is installed. For more information on

feature items, see the Feature/Option Configuration File Maintenance

section of the BOMP manual.

|

|

End Item Code (continued)

|

If the item is a kit item, a

K may be entered here. For more information on kit items, see the Kit

File Maintenance section of this manual. Except for F and K,

any character entered here will not be used by the package and may have any

meaning the user desires.

The following are examples of possible uses:

E = End

Item only

C = Component

only

R = Replacement

part (also used as a component).

B = Both

end item or component.

|

|

Rollup Price?

|

Y or N.

This field will only be displayed if field #73 above

contains a K for Kit Item. Enter Y to rollup a kit item's

price from the prices of its components. Enter N to take the price of

a kit item from the Price Code File Maintenance from field #16 Selling

Price in Item File Maintenance.

Defaults to Y.

|

|

74. P And Ic Code

|

3 alphanumeric characters.

This code is used to group

items for production and inventory control for management purposes.

|

|

75. Order Policy Code

|

1 alphanumeric character.

This field is used solely by the Material

Requirements Planning [MRP] package to specify how you want to generate

planned orders for the inventory item. The code designates the planning

method to be used by Material Requirements Planning. It can

have one of the following values:

L = Lot

P = Period

Requirements

R = Reorder

Point

Blank = Not

Planned

Lot

means that every time there is a requirement for the item, a planned order

will be generated. For example, every time a customer order generates a

requirement for the item, an MRP package will generate an order for

that quantity of the item.

|

|

Order Policy Code (continued)

|

In the Period Requirements

planning method, one planned order is created to cover all requirements

within a period.

In the Reorder Point method, planned orders are created

when the item's projected quantity on‑hand falls below its reorder

point.

If this field is blank, MRP

will not read this item during a regeneration.

|

|

76. MRP Time Fence Days

|

3 numeric digits (999).

This allows the planner to

firmly set a short-term schedule for an item and prevent MRP from

making recommendations for changes within the specified number of days from

the date of the material plan regeneration. For more information, see the

time fence section of the MRP manual.

|

|

77. Drawing Release No

|

6 alphanumeric characters.

This is the number which

engineering assigned to the engineering drawing for the item.

|

|

78. Drawing Revision No

|

2 alphanumeric characters.

Each time a revision is made

to the engineering drawing for the item, this field would be updated. A

drawing is usually designated by a Drawing Number and a Drawing Revision

Number.

|

|

79. Routing Release No

|

6 alphanumeric characters.

This is the routing number

assigned by engineering to identify the routing for the item. This engineer

routing might be very detailed, giving exact specifications for the tooling

of every part, which goes to make up the item.

|

|

80. Routing Revision No

|

2 alphanumeric characters.

Each time the above routing

is updated, this revision number would be updated.

|

|

81. Routing Number

|

5 alphanumeric characters.

This is the number of the

routing for a Standard Product Routing File, which designates the primary

routing of the item through the shop. This routing is not as

detailed a routing as the engineering routing. It may show only which

machines to which the item travels, with a brief description of the operation

done at each machine.

|

|

82. Planning Period

|

3 numeric digits (999).

Refer to the above

description of the Order Policy code. If the period requirements method of

planning is used, this field designates the length (in days) of the planning

periods.

|

|

83. Planning Lead Time

|

3 numeric digits (999).

This is the duration, in

calendar days, between the ordering of the part, either from an outside

vendor, or from the manufacturing facility and the actual receipt of the item

into inventory. This field is used during any MRP requirements

generation.

|

|

84. Planning Order Mult

|

4 numeric digits (9999).

Plan orders of the item in

multiples of this. For example, there may only be a requirement for 25

gallons of liquid item, but you may order it in 50 gallon containers, so the

item is ordered in multiples of 50 gallons.

|

Display Only Fields

|

Name

|

Type and

Description

|

|

Stock Status Code

|

1 alphanumeric character.

This is not an entered

field. It is updated when the Reordering Advice Report is printed to

show that the item hit reorder level or out‑of‑stock status when

the report was last printed. The item will not then be printed on a

subsequent Reordering Advice Report, until a receipts transaction for

the item is processed. The field will have one of three values, either 1) blank,

meaning

|

|

Stock Status Code (continued)

|

that it has not appeared on a Reordering Advice Report

since a quantity of the item was last received into stock, 2) R,

meaning that the item had hit its reorder point when the report was last

printed, or 3) O, meaning that the item was out‑of‑stock

when the report was last printed.

|

|

Low Level Code

|

2 numeric digits (99).

This is not an entered field. It is updated by the Bill

of Material Processor applications if that package is in use.

This field indicates the

lowest level where this item appears in any Bill of Material.

For example, the item may appear at level 3 in one bill, and at level 4 in

another. In this case, the Low‑Level code would be 4.

|

|

Active Orders

|

5 numeric digits (99999).

This is not an entered

field. It is updated by the Customer Order Processing applications if

that package is in use. This is the number of outstanding orders on which

this item appears. If this number is greater than zero, the item cannot be

deleted.

|

|

MRP Multi‑Loc Qty Oh

|

A standard quantity

accumulator format with an optional minus sign.

This is not an entered

field. It is used by MRP to sum the quantity on‑hand at those

locations indicated by the MRP Setup as netting locations.

|

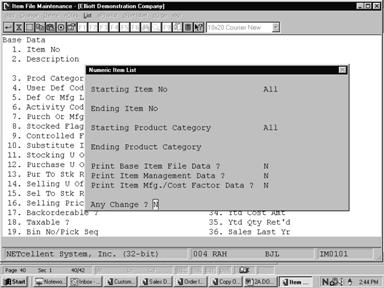

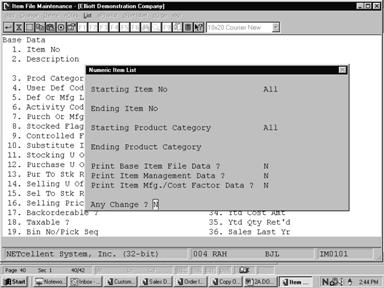

Numeric List

|

Name

|

Type and

Description

|

|

Starting Item No

|

15 alphanumeric characters.

Enter the starting item number for the range to print.

Press the F7 key to search by item number.

Press the F8 key to search by item description.

Defaults to All

items.

|

|

Ending Item No

|

15 alphanumeric characters.

Enter the ending item number for the range to print.

Press the F7 key to search by item number.

Press the F8 key to search by item description.

Defaults to the starting

item number.

|

|

Starting Product Category

|

3 alphanumeric characters.

Enter the starting product category for the range to

print.

Defaults to All

product categories.

|

|

Ending Product Category

|

3 alphanumeric characters.

Enter the ending product category for the range to

print.

Defaults to the starting

product category.

|

|

Print Base Item File Data ?

|

Y or N.

Enter Y to print the base item data from the

first screen of the Item File.

Defaults to N.

|

|

Print Item Management Data ?

|

Y or N.

Enter Y to print the item management data from

the second screen of the Item File.

Defaults to N.

|

|

Print Item Manufacturing Data?

|

Y or N.

Enter Y to print the item manufacturing data

from the second screen of the Item File.

Defaults to N.

|

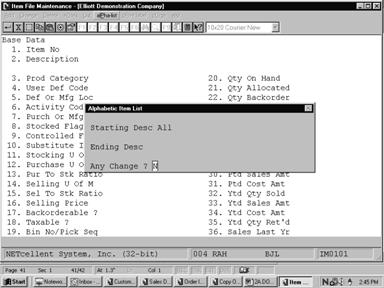

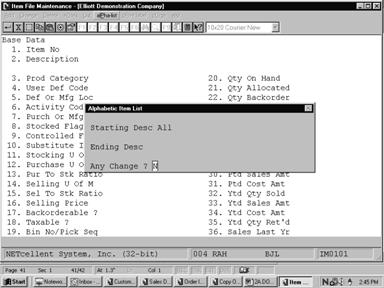

Alpha List

|

Name

|

Type and

Description

|

|

Starting Desc

|

30 alphanumeric characters.

Enter the description of the starting item for the

range to print.

Defaults to All

items.

|

|

Ending Desc

|

30 alphanumeric characters.

Enter the description of the ending item for the range

to print.

Defaults to the starting

item.

|

Date

filled out ________by ________ ADD CHANGE DELETE

Page 1

of 5

ITEM FILE MAINTENANCE LOAD SHEET - BASE DATA

1)

Item Number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2)

Description_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3)

Product Category _ _ _

4)

User Defined Code _ _

5)

Def Or Mfg Loc _ _

6)

Activity Code _

7)

Purch Or Mfg? _

8)

Stocked Flag Y N

9)

Controlled Flag Y N

10)

Substitute Item _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11)

Stocking U Of M _ _

12)

Purchase U Of M _ _

13)

Pur To Stk Ratio _ , _ _ _ . _ _ _

14)

Selling U Of M _ _

15)

Sel To Stk Ratio _ , _ _ _ . _ _ _

16)

Selling Price _ _ _ , _ _ _ . _ _ _ _

17)

Backorderable ? Y N

18)

Taxable ? Y N

19)

Bin No/Pick Seq _ _ _ _ _ _ _ _

Date

filled out ________by ________ ADD CHANGE DELETE

Page 2

of 5

ITEM FILE MAINTENANCE LOAD SHEET - BASE DATA

20)

Qty On Hand _ _ _ , _ _ _ , _ _ _ . _ _ _

21)

Qty Allocated _ _ _ , _ _ _ , _ _ _ . _ _ _

22)

Qty Backorder _ _ _ , _ _ _ , _ _ _ . _ _ _

23)

Qty On Order _ _ _ , _ _ _ , _ _ _ . _ _ _

24)

Average Cost _ _ _ , _ _ _ . _ _ _ _

25)

Last Cost _ _ _,_ _ _,_ _ _._ _ _

26)

Standard Cost _ _ _,_ _ _,_ _ _._ _ _

27)

Date Last Sold _ _/_ _/_ _

28)

Qty Last Sold _ _ _,_ _ _,_ _ _._ _ _

29)

Ptd Qty Sold _ _ _,_ _ _,_ _ _._ _ _

30)

Ptd Qty Sold _ _ _,_ _ _,_ _ _._ _

31)

Ptd Cost Amt _ _ _,_ _ _,_ _ _._ _

32)

Ytd Qty Sold _ _ _,_ _ _,_ _ _ _ . _ _ _

33)

Ytd Sales Amt _ _ _ , _ _ _ , _ _ _ . _ _

34) Ytd

Cost Amt _ _ _ , _ _ _ , _ _ _ . _ _

35)

Ytd Qty Ret'd _ _ _ , _ _ _ , _ _ _ . _ _ _

36)

Sales Last Yr _ _ _ , _ _ _ , _ _ _ . _ _

Date

filled out ________by ________ ADD CHANGE DELETE

Page 3

of 5

ITEM FILE MAINTENANCE LOAD SHEET - MANAGEMENT DATA

37)

Commsn Method _

38)

Commsn Pct/Amt _ _ , _ _ _ . _ _

39)

Target Margin _ _ _

40)

Matl Cost Type _

41)

Reorder Level _ _ _,_ _ _,_ _ _._ _ _

42)

Order Up To _ _ _,_ _ _,_ _ _._ _ _

43)

Recom Min Order _ _ _,_ _ _,_ _ _._ _ _

44)

Lead Time _ _ _

45)

Def Vendor No _ _ _ _ _ _

46)

Order Minimum _ _ _,_ _ _,_ _ _._ _ _

47)

Order Multiple _ _ _ _

48)

Commodity Code _ _ _ _

49)

Weight _ _,_ _ _._ _ _

50)

Inventory Class _

51)

Cycle Count Code _

52)

Date Last Cntd _ _/_ _/_ _

53)

Buyer Or Analyst _ _

Date

filled out ________by ________ ADD CHANGE DELETE

Page 4

of 5

ITEM FILE MAINTENANCE LOAD SHEET - MANAGEMENT DATA

54)

Usage Ptd _ _ _,_ _ _,_ _ _._ _ _

55)

Usage Ytd _ _ _,_ _ _,_ _ _._ _ _

56)

Usage Last Yr _ _ _,_ _ _,_ _ _._ _ _

57)

Average Usage _ _ _,_ _ _,_ _ _._ _ _

58)

Usage Wght Fctr _._ _

59)

Safety Stock _ _ _,_ _ _,_ _ _._ _ _

60)

Safety Factor _._

61)

Usage Filter _._

62)

Start Sale Date _ _/_ _/_ _

63)

End Sale Date _ _/_ _/_ _

64)

Sale Price _ _ _,_ _ _,_ _ _ _

65)

Economic Ord Qty _ _ _,_ _ _,_ _ _._ _ _ _

66)

Serialized Item Y N

67)

Length Of Wrnty _ _,_ _ _._ _ _

68) Do

Price Breaks Apply?

69) Do

Discounts Apply? _ _ _ _ _ _ _

Date

filled out ________by ________ ADD CHANGE DELETE

Page 5

of 5

ITEM FILE MAINTENANCE LOAD SHEET - MANUFACTURING DATA

70)

Average Error _ _ _ , _ _ _ , _ _ _ . _ _

_

71)

Sum Of Errors _ _ _ , _ _ _

72)

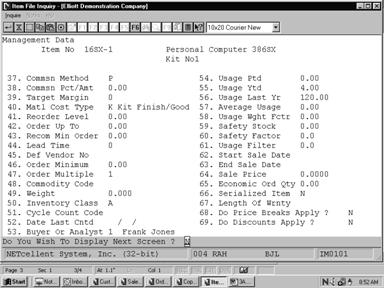

Master Sched Item? Y N

73)

End Item Code _

74) P

And Ic Code _ _ _

75)

Order Policy Code _

76)

MRP Time Fence Days _ _ _

77)

Drawing Release No _ _ _ _ _ _

78)

Drawing Revision No _ _

79)

Routing Release No _ _ _ _ _ _

80)

Routing Revision No _ _

81)

Routing Number _ _ _ _ _

82)

Planning Period _ _ _

83)

Planning Lead Time _ _ _

84)

Planning Order Mult _ _ _ _

****Display

Only****

Stock

Status Code _

Low

Level Code _ _

Active

Orders _ _ _ _ _

MRP

Multi-Loc Qty Oh _ _ _ , _ _ _ , _ _ _ . _ _ _

Item File Maintenance (Item Search By Description)

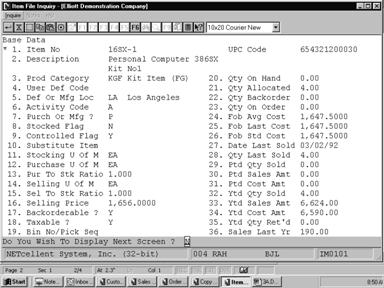

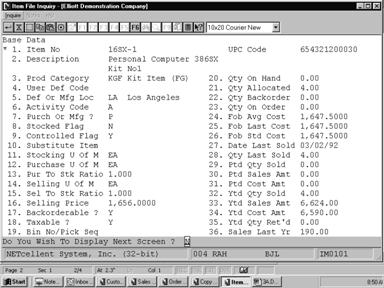

Item Base Data (Screen #1)

Item Management Data (Screen #2)

Item Manufacturing Data (Screen #3)

Item Notes

Numeric Item List

ScreensREPORTS

ScreensREPORTS

Alphabetic Item List

N U M E R I C I T E M L I S T

Range: All Items

All Product Categories

Summary Report

1. Item No 16SX‑1

2. Description Personal Computer 386SX 3. Prod Category KGF Qty

On‑Hand .000

Kit No1 Price 1,656.0000 Qty On‑Order

.000

1. Item No 16SX‑2

2. Description Personal Computer 386SX 3. Prod Category KGF Qty

On‑Hand .000

Kit No2 Price 1,672.0000 Qty On‑Order

.000

1. Item No 16SX‑3

2. Description Personal Computer 386SX 3. Prod Category KCM Qty

On‑Hand .000

Price 1,472.0000 Qty On‑Order .000

1. Item No BOX‑386‑1

2. Description Basic SM Box w/7 Exp 6‑16 1‑8 3. Prod

Category Qty On‑Hand 731.000

Price 399.0000 Qty On‑Order .000

1. Item No BOX‑386‑2

2. Description Adv Box HDps 8 Exp 32 5‑16 2‑8 3. Prod

Category Qty On‑Hand 421.000

Price 499.0000 Qty On‑Order .000

1. Item No CHAR‑GEN

2. Description Character Generator At 25 Meg 3. Prod Category CVD Qty

On‑Hand 10.000

Character ‑ Gen ‑ 25 Price 9.6000 Qty On‑Order

40.000

1. Item No

CLOCK 2. Description 25 Meg Clock For Mother Board 3. Prod

Category A Qty On‑Hand 15.000

Clock ‑ 25M Price 15.5000 Qty On‑Order

20.000

A L P H A B E T I C I T E M L I S T

Range: All Items

Item‑No

Description Prod U‑Of Average Price

Qty Qty Reorder B/O Tax Pick

Cat

Meas Cost On‑Hand Alloc Level Ok?

? Seq

K‑SX2‑1.2

1.2 Drive For Personal KCM EA 180.0000 210.0000

17.000 .000 .000 Y Y

Computer

K‑1.2DRIVE 1.2

Drive For Personal KCM EA 252.0000 260.0000 16.000

5.000 .000 Y Y

Computer

K‑SX2‑1.44

1.44 Drive For Persoanl KCM EA 190.0000 210.0000 16.000

.000 .000 Y Y

Computer

K‑SX3‑1.44

1.44 Drive For Personal KCM EA 168.0000 180.0000

9.000 .000 .000 Y Y

Computer 386

K‑1.44DRIVE 1.44

Drive For Personal KCM EA 163.0000 170.0000 14.000

5.000 .000 Y Y

Computer

K‑SX1‑1.44

1.44 Drive For Personal KCM EA 189.0000 195.0000

18.000 2.000 .000 Y Y

Computer

K‑SX3‑101KB

101 Keyboard For PC KCM EA 119.0000 128.0000

19.000 .000 .000 Y Y

REPORTS

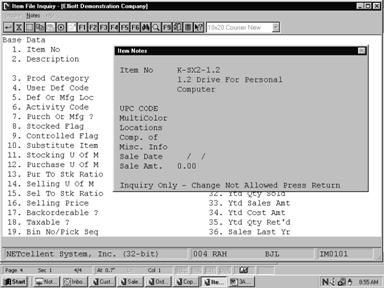

Many

occasions may arise where you will want to quickly inquire into the Inventory

Item File. Item File Inquiry gives you a rapid procedure to display on the

screen all or a portion of an Inventory Item. This application allows you to

view the item without the ability to change any of the information displayed.

The Notes Inquiry allows you to view the pertinent information that was defined

in Item File Maintenance, Notes application. All of the information and field

descriptions that are displayed to the screen may be found in the Item File

Maintenance section under Maintenance in this manual.

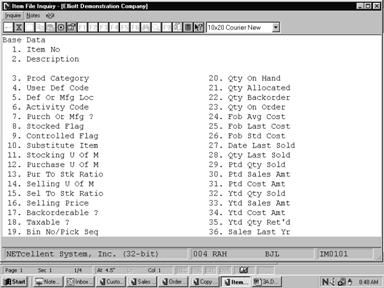

Select Item File from the pull down I/M

Inquiry window. The following screen will then be displayed:

Item File Inquiry Entry Screen

The following options are available:

* Select the desired mode

from the Item File menu bar

* Enter the data requested

on the screen

To return to the menu bar, press the ESC or

F10 key. To leave this application, press X for EXIT when positioned at the

menu bar.

Screens

Item File

Inquiry (Screen #1)

Item File

Inquiry (Screen #2)

Item File

Inquiry (Screen #3)

Item Notes