|

|

Global SetupBill of LadingApplication OverviewThis

feature is designed to print a Bill of Lading form used by trucking companies

for shipping. Our primary goal is to

save time by filling out the Bill Of Lading forms for the shipping department

staff. In order to use this feature,

users are required to have one of the following forms: 1) A short form which is

seven inches long, RapidForm form number 25654, or 2) A long form which is 11

inches in length, form number 22824. For

the best result, the long form is recommended. A sample of each form follows the last page

of this enhancement. Run InstructionsBefore

utilizing the function of printing a bill of lading, you need to set up Bill of

Lading through the setup process. You

can choose to either accept the default settings or customize the printing. Elliott

main menu à Util setup à Global setup à cop-ctl à Bill of

lading

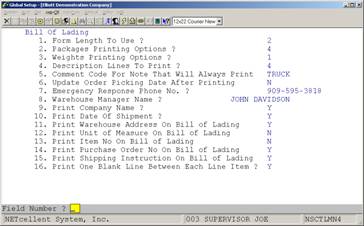

Figure 4A.1 shows

the setup screen for Bill of Lading. 1. Form Length To

Use? This flag controls the type of Bill of Lading

form to use (4A.2). Enter “1” if you

wish to use the RapidForms Short Form #2565, or “2” for the long form

#2282. For the best result, the long

form is recommended.

Figure 4A.2 2.

Packages Printing Options? On the Bill Of Lading

form, the user has to specify the number of packages. This question gives the user three options: 1)

Always Use Qty To Ship, 2)

Select During Order Entry, and 3)

Leave Blank. 4)

Qty-Ship/Item User Amount If

the user enters 1, the system will grab the Qty Shipped information from the

Order Line Item file to put it on the form.

If you enter 2, system will require the user to specify the number of

packages in the Order Line Item screen manually as is shown in Figure 4A.3.

Choosing option 3 will leave the No. Packages column blank and the warehouse

staff will fill it out manually. Choose

option 4 = Equal Qty-Ship/Item User Amount.

Item User Amount is a convention in Elliott to stand for Qty per Box for

each item. If you do specify this

information, then system can automatically determine number of box for each

line item when printing Bill of Lading. 3.

Weight Printing Options? This

flag controls the weight printing on the Bill of Lading form. You have three options: 1)

Item Weight, 2)

Leave Blank, and 3)

Manual Entry. Option

1 basically will retrieve the Item Weight from the Item File. Option 2 requires the warehouse staff to fill

in the weight manually. Option 3 will

prompt you to enter the total weight for each line item during order entry. 4.

Description Lines To Print? This

flag gives you four options to control how the package description should be

printed on the Bill Of Lading form. They

are: 1)

Line Item Desc 1 + Usr Def Code Desc, 2)

Line Item Desc 2 + Usr Def Code Desc, 3)

Both Line Item Desc + Usr Def Code

Desc, and 4)

User Def Code Desc Only. User

defined code stands for the category of the item. For example, if you are a monitor

manufacturer, you probably will not put your item description of “Model 7682

1024x768 15” Flat” on the bill of lading since the trucker wouldn’t understand

what it means. Chances are, you will put

something like ‘15” VGA Monitor’ on the bill of lading. The trucker should be able to understand this

and it conforms to the Department of Transportation’s regulation. You will need to set up a user defined code

of ‘15” VGA Monitor’ and indicate the item’s user defined code in item file

maintenance. If

you enter “1,”, the first line of the Line Item Description and the User

Defined description will be printed on the form, wereas option “2” will make

the system print the second line of the Line Item Description in the Order Line

Item file plus the description in the User Defined File, or “3” for all the

Line Item Description 1, 2 and the User Defined File description; option “4”

will have only the User Defined Description printed in the Package Description

column of the form. When you specify

“4,” the system can also consolidate bill of lading line items for line items

on the order with identical user defined codes. 5.

Comment Code for Note That Will Always Print If

this is your first time using this enhancement, we suggest you leave this field

blank and get familiar with our Note Function Enhancement first. The code specified here refers to the notes

associating with this code in the Note Windows.

This flag allows you to select a predefined note that will always print

on the Bill of Lading. This is a global

setting. Once set, all bills of lading will be printed with this note. If you do not have such a global note to

always print on the bill of lading, you should leave this field blank. More specific notes like order, customer,

item or line item notes can also be printed on the Bill of Lading (refer to the

Note Function Enhancement). 6. Update Order Picking Date After

Printing? If you are using Bill of Lading as your

picking ticket, answer “Y” to this question.

If you print a picking ticket separately from the Bill of Lading, you

should answer “N.” 7. Emergency Response

Phone No.? The

Department of Transportation requires you to provide an Emergency Response

Phone Number in case of a disaster, like a truck spill on the highway. 8. Warehouse Manager

Name? You

can enter name of the person in charge of the organization’s shipments. The name entered here will be designated as a

contact person in the company for emergency dealings. 9.

Print Company Name? Depending

on whether you have a generic form or a pre-printed form with your company’s

name and logo, you will answer “Y” or “N” accordingly. 10. Print Date of

Shipment? This

is a Yes/No flag triggering the printing of the shipment date on the top of the

BOL. The date will be entered during the

printing routine. 11.

Print Warehouse Address On Bill of Lading? Answer

“Y” if you wish to print the warehouse address on the Bill of Lading. 12.

Print Unit of Measure on Bill of

Lading? Answer

“Y” to use this function. 13.

Print Item No. On Bill of Lading? Answer

“Y” to use this function. 14.

Print Purchase Order No. On Bill

of Lading? If

you are using the Bill of Lading as a picking ticket, chances are you want to

answer “Y” to print the customer purchase order on the Bill of Lading. 15.

Print Shipping Instructions On

Bill of Lading? Answer

“Y’ to use this function. 16.

Print One Blank Line Between Each

Line Item? Answer

“Y” to use this function. USING BILL

OF LADING

Information On

Bill Of Lading There

are two files that the user has to maintain to ensure the correct information

will be printed on the bill of lading forms.

The first file is the User Defined File, and the second is the Item

File. A. User Defined File-

The

User Defined File controls the information printed on the bill of lading

forms. The records created in this file

will be used in the Item File so that each individual item has clear

information for the bill of lading. As

its name suggests, the User Defined File can be named by the user. Usually the more descriptive the literal, the

better it is for the user. The literal

defining of this file is done in Inventory Maintenance (please refer to that

manual). The user may either choose the

default value or enter any custom literal.

In our example, we use the default code, User Defined Code, as the

literal in the User Defined File. The

User Defined Code will later be used in the Item File for an item so that the

corresponding User Defined Code Desc, User Defined Code Class, Hazardous

Material, Item Category, and the ERG# information can be printed on the bill of

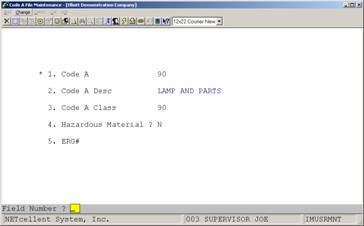

lading forms. Figure 30.1 illustrates

what we have created for this file.

Figure 4A.5. A User

Defined record has been built for the Item File to print the information

entered here on the bill of lading forms. 1) User Def Code-- A code uniquely

identifying each User Defined record. It

will be used in the Item File identifying which shipping category of the

trucking company that a particular item belongs to. 2) User Def Code Desc-- A detailed

description of a shipping category of the trucking company. This piece of information will be printed in

the column “KIND OF PACKAGE, DESCRIPTION OF ARTICLES, SPECIAL MARKS AND EXCEPTIONS”

on the form. 3) User Def Code Class-- This field

specifies which class of rate that the trucking company charges for the item’s

corresponding shipping category code (equivalent to User Def Code in our

example). It will be printed in the

column of “CLASS OR RATE” on the form. 4) Hazardous Material-- This field will

be printed in the column of “HM,” which indicates whether the item’s

corresponding shipping category code contains hazardous material or not. The user answers either “Y” or “N” to this

question. If the shipment contains hazardous materials, the long form must be

used. 5) ERG#-- This field has been regulated

recently by the government. It requires

the user to enter a two-digit Emergency Response Group Code for emergency

response personnel to provide proper services when there is a hazardous

material spill. B. Item File-

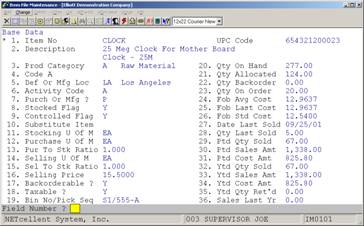

Once

the user sets up the User Defined File, the records can be used to print useful

information on the bill of lading. Figure 4A.6 shows that Field 4 contains the

code description that we have seen in Figure 4A.5. “90” is used for the Item No Clock.

Figure 4A.6 In the Item

File, the user has to enter the code that he/she established in the User

Defined File to print the information on the bill of lading. HOW TO PRINT

THE BILL OF LADING There

are three files involved in the Bill Of Lading printing. They are the Ship Via File, the Customer File

and the Order Header File. Each one of

these have a chain reaction effect on the other. The user has to make sure that these files

are set up accurately to print out the bill of lading. Therefore, we will discuss these four files

as well as the bill of lading printing. Remember, it is a pre-requisite to

establish a correct relationship among these related files. A. The Chain Reaction Effect This effect derives from the fact that

the bill of lading printing is controlled by a flag set up in the Ship Via

File. In other words, when the user

enters the customer information in the Order Header, he/she has to be certain

that this particular customer has a Ship Via code that contains a printing

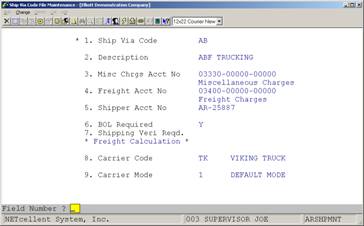

control flag. Figure 4A.7 depicts this

so-called chain reaction effect. The

detailed linking relationship will be stated in paragraph B, C, D and E in this

section. B.

Ship Via File

The Ship Via

Code File Maintenance contains the flag that controls printing of the Bill of

Lading (Figure 4A.7). C.

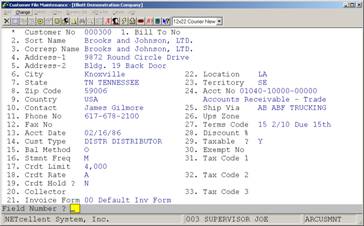

Customer File

As paragraph A and B state, the Ship Via

has to be specified in the Customer File.

Therefore, the Ship Via code AB that is set up with a legitimate Carrier

Code can be applied to the customer record.

The Ship Via field for B&J Enterprises (Figure 4A.7b) is AB. The user will notice later that when we use

this particular customer during the Order Entry session, the corresponding bill

of lading information can be printed.

Figure 4A.7 Field 6 prompts “BOL Required”,

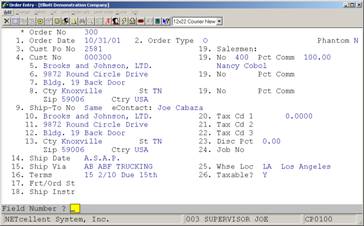

answer “Y” to print BOL. D. Order Header FileThis is the last setup step for the user

to go through to print out the bill of lading information. In the previous paragraph, we have

established the correct Ship Via code for Flaum Consultants, Inc., so we will

continue using this example to proceed with the order entry. Figure 4A.8 shows a customer set up to use

BOL.

Figure

4A.7b

Field 25 of

this customer record indicates that TC is being used for the future bill of

lading printing. E. Bill Of

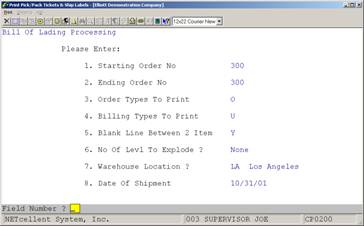

Lading Printing

After setting up this enhancement, you can now begin to print Bills of Lading. Select COP à Processing à Print Pick/Pack Tickets & Ship Labels à Print à Bill Of Lading, and then fill in the Bill Of Lading Processing screen as in Figure 4A.9. For the Order Types To Print field, the user has three options: 1) printing “O”, Type O orders, 2) “I”, Type I orders, and 3) “B”, both types of orders. Since the user is assumed to understand different types of orders in COP, the meanings of these three types will not be discussed in this documentation.

Figure

4A.8 B&J Enterprises is

a “bill-of-lading legitimate” customer in our example and is used for Order

Entry. After the user specifies the order

type(s), the system will prompt the user to specify the Billing Types To

Print. He/she can then choose “B”illed

types only, “U”nbilled types only, or “A”, both. Field 5 in this printing screen is the

Blank Line Between 2 Items. The user may

answer “Y” to leave a blank line between 2 items or “N” to have no blank lines.

Figure

4A.9 Bill Of Lading printing header screen. It allows the user to print either “O” type

of orders, “I” type of orders or both. Checking Criteria For The Bill Of Lading

If

the Bill of Lading is not printing, please check the following: 1.

Order Header File: The order number must be between the

starting order and ending order (Screen Criteria 1 & 2). This order cannot be posted. The order type cannot be a Credit Memo

(“C”). The order type to print is “O” (Screen

Criteria 3), and the order type is “O”. The order type to print is “I” (Screen

Criteria 4), and the order type is “I”. The billing type to print is “B” (Screen

Criteria 4). The order is selected or invoiced. The billing type to print is “U”

(Screen Criteria 4), and the order is complete. The order Ship Via Code must exist

(Order Header Screen Field 15). Use the Freight Calculation

enhancement (license and control). The carrier code in the Ship Via Code

exists (Ship Via Code Maintenance Screen

Field 5). 2.

Order Line Item File No Comment Item. The line item cannot be posted. The line item qty. to ship is not

<= 0. The billing type to print is “B”

(Screen Criteria 4), and the line item is selected. Customer Item Reference SetupApplication OverviewSome customers place orders using their item numbers rather than

yours. Without a proper

cross-referencing system, it may not be easy to understand which item the

customer is referring to and could lead to situations such as shipping the

wrong item, consuming time to verify the correct item ordered, or even

possibly, losing the sale. This

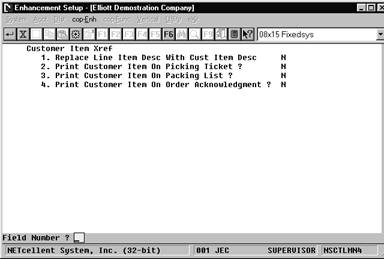

application allows defining a cross-reference system. Run InstructionsBefore

setting up customer cross-reference item numbers, you must define where and how

you want to use them. To do this, go to: Main

Menu ® Util-setup ® Global setup ® cop-Ctl ® customer Item x-ref. The following screen will then be displayed:

Customer Item Xref Setup Screen Entry

Field Descriptions

* Complete the setup screen to your

specifications. Using Customer Item Cross ReferenceMaintaining

Customer Item File

Before

understanding which items your customers are referring to by using their item

numbers, you need to build a cross reference table to match customers item

numbers to your item numbers. To do this,

select COP à Maintenance à Customer Item File. The maintenance screen appears. This

screen consists of three major fields to build a cross-reference record for a

customer’s specific item. Once the records are created, the user can use the

search function key at COP line entry to find the customers item number to fill

in the Item No. field.

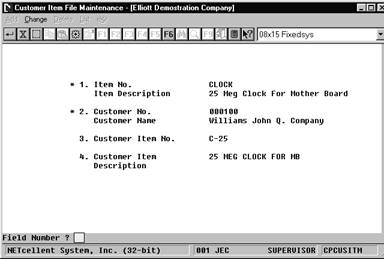

Customer Item File Maintenance

Screen – Change Mode Like other Elliott

maintenance program windows, the user can also perform Change, Delete, and List

for Customer Item records. Utilizing

Customer Item Cross Reference in COP Line Item entry

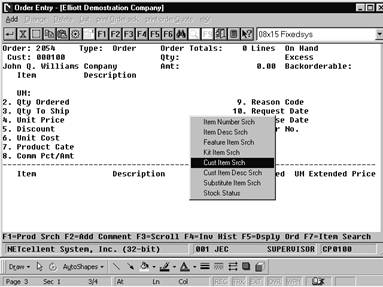

a. Customer Item Search At the Item

No. field, press the F7 key to select Cust Item Search. Choose to search by Item Number or Customer

Item Description. In the search screen,

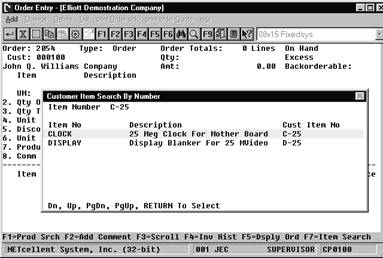

type in the Item No. or Customer Description as described by the customer. The search by Customer Item will display your

Item Number, Description, and Customer Item Number. The search by Customer Description will

display your Item Number, Customer Description, and Customer Item number.

F7 Key – Customer Item Search

Customer Item Search by Customer

Item Number Changing

A Customer Item Record On-the-fly

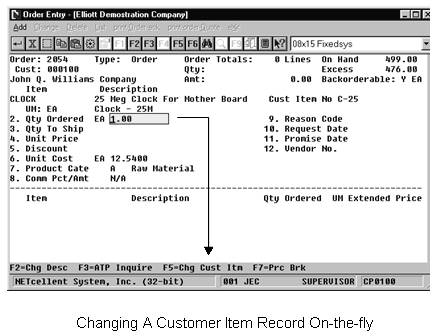

Upon the selection of the item being

ordered, the screen will display the Customer Item No. to the right of your

Item No. and move the cursor to the field 2, (Qty Ordered). At this point, the

user can change the Customer Item No. if the customer requests changing it or

the description. Press F5, (bottom menu

bar options), and the system will move the cursor back to the Customer Item

No. field for changes to Item Number, Description 1, and Description 2.

Printing

Customer Item No. On Invoices and Picking Tickets

If you have turned on the control flag

to print customer item number on the picking tickets in the Enhancements Setup,

the Customer Item No. will be printed on the invoices as well as the picking

tickets if there are any. To print the Customer Item No. on the invoice, you

must set up an extra printing field for the invoice form that is used

for billing. There is no setup required

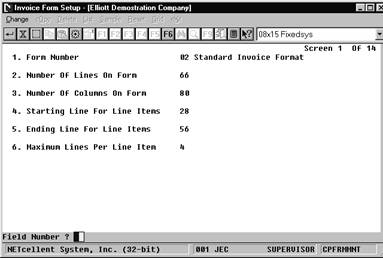

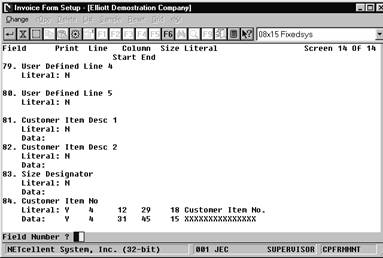

for picking tickets. Invoice Printing With Customer Item No. Setup Go to COP à Util_Setup à Invoice Form

Setup, and then select Change to bring up the desired form to which you would

like to add the extra field.

Invoice Setup Screen Field No. 6: Make sure to consider the extra line you will

put in for printing the Customer Item No. Proceed to the last screen of this

Invoice form format to enter the printing specification for the Customer Item

No. and/or Customer Item Description.

Invoice Setup Screen Field

84 shows the printing specification for the Customer Item No. The

specifications for this field are user-defined to allow you specific invoice

forms for specific customers.

Picking ticket – Line Item Example (When setup flag = “Y” to print Customer Item Number on Picking

ticket)

Invoice – Line Item Example (When setup field 1, Replace Line Item Description with Customer Description, flag = “Y” Freight CalculationApplication OverviewThe

Freight Calculation function provides you with a convenient and flexible method

of calculating freight charges. Perhaps,

in the past, you have had to look up the carrier freight charge and the carrier

freight zone to figure out what amount to bill, and then look up other charges

such as AOD charge, COD charge, hazardous material charge, etc. With the Freight

Calculation feature, the system will handle all the freight calculations

for you in just a few seconds. It not

only saves you time, but is also very simple and easy to use. Freight

Calculations Summary

Freight calculations are done in the

billing screen of COP Order Processing.

If would like access to the billing screen for “O” type and “Q” type

orders, you can enable feature in Order Billing Screen setup. You can also perform freight

calculations for an order from the COP Inquiry Menu. This is especially useful when you need to

discuss shipping charges with your customer.

All the information required for

freight calculations is predefined in four files for the following carriers: 1. UPS 2. Fed Ex 3. RPS 4. NOTE: You have the

ability to add additional carriers. The

four predefined A/R files containing all carrier information are: 1. Carrier File 2. Carrier Mode

File 3. Freight Rate

File 4. Freight Zone

File Note: The Freight

Zone File is location dependent. Setting

up an additional location for your geographical

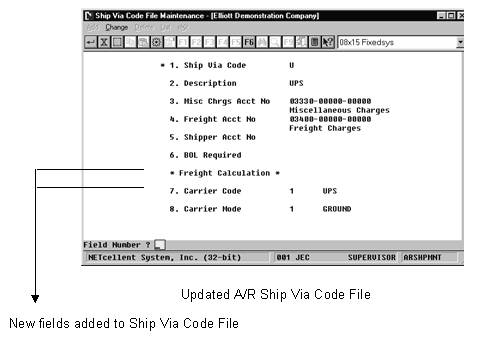

area will be discussed later in detail. Once you have properly setup the above

four files in Accounts Receivable Maintenance, you must update the two

new fields added to the A/R Ship Via Code file.

This file tells the system what information to use for freight

calculations. |

|

Name |

Type and Description |

|

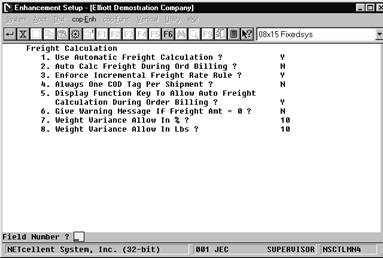

1. Use

Automatic Freight Calculation |

This flag must be set to “Y” to turn on the Automatic

Freight Calculation. “Y” adds two new fields to the A/R Ship Via Code file. |

|

2. Auto Calc

During Freight During Order Billing? |

Answer “Y” if you want to calculate freight

automatically during order billing. For an accurate freight amount, the items

ordered must have a weight amount set up in the Inventory Item File. Select “N” if you want to manually enter the weight,

value, number of boxes shipped, and adjust any additional or associated

charges such as COD, AOD, Call tags, Hazardous and Oversized packages. |

|

3. Enforce

Incremental Freight rule Table? |

This flag is an editing tool when entering freight

rates. It will force you to increase

the rates when the weight is increased. |

|

4. Always One COD Tag Per Shipment? |

This

flag provides users with flexibility when using the Automatic Freight

Calculation enhancement. If this flag is set to "Y", the freight

calculation only counts one COD tag charge for the entire shipment. If set to

"N", Automatic Freight Calculation will charge one COD tag for each

box if COD service is used. By

applying one COD tag per shipment, the high cost of COD service charges can

be avoided. For example, assume that you want to ship ten boxes to a customer

while the value of each box is low. If we implement one COD tag for each box,

the service might be too costly for the customer to accept. Therefore, one

COD tag per shipment is more appropriate and reasonable in this case. |

|

5. Display Function Key To Allow Auto Freight

Calculation During Order Billing? |

If

you answer “Y” to this question, the system will display a function key in

the order-billing screen that allows automatic freight calculation or manual

freight entry. |

|

6. Give Warning

Message If Freight Amount = $0.00 |

Answer

“Y” to enable this function. |

|

7.

Weight Variance Allow

In %? |

You

can enter a number to represent the discrepancy percentage, which is

calculated as Remaining Weight/System Calculated Weight. If the discrepancy

percentage is greater than the percentage amount entered, a warning will be

issued to the user. For example, if the user entered 5 (actually means 5%) as

a Weight Variance, the permissible range for the discrepancy percentage must

fall in the range between 0 and 0.05. |

|

8. Weight Variance Allow In Lbs.? |

This

flag works in the same manner as Weight Variance Allow in %. The number entered here represents an

absolute amount of weight that the discrepancy allows. For example, if the

user entered Weight Variance = 5, it means the permissible range for the

remaining weight must fall in the range between 0 and 5 pounds. |

Freight

Calculation Predefined A/R Files

|

A/R FILES |

LOCATION AND FILE DESCRIPTION |

|

1. Carrier File (Codes) |

A/R Maintenance: Contains all the carriers and

features provided by each carrier. You should review this file to see if any changes

need to be made to suit your specifications, as well as, adding an additional

carrier of your choice. |

|

2. Carrier Mode File |

A/R Maintenance: Contains all the different

methods of shipment available for a specific carrier |

|

3. Freight Rate File |

A/R Maintenance: Contains freight rates for all

carriers. Rate tables for UPS, RPS,

Fed Ex, and U.S. Postal Service are provided. |

|

4. Freight Zone File |

A/R Maintenance: Cross-links locations to zone

numbers for all the carrier modes. Freight Zone File is location dependent, and

since we set it up based on our location, it only works for areas with zip

codes ranging from 91001 to 91899. If

you are located in this area, you do not need to change anything. If you are

not in this area, you can either create your own Freight Zone File or change

the mismatched portion of our file in Freight Zone File Maintenance. If you

need to make a change in our Freight Zone File, you do not need to change the

zone setup for Federal Express, UPS Blue, or UPS Red because they apply to everyone,

regardless of area. |

|

INSTALL

NOTE: |

These four files must be initialized for a new

company setup and then imported from the Elliott root directory. Once this has been completed, they must be

setup in the exact number sequence.

After they have been setup, the A/R Ship Via codes must be updated

with the Carrier Codes and Carrier Modes. These four files and the updated

Ship Via codes must be set up in order to correctly use freight calculations |

REMINDER: After you have

added and reviewed the four predefined files, you must update the A/R Ship Via

Codes for the Carrier Code and Carrier Mode before you begin using the Freight

Calculation feature in COP Order Entry or COP Inquiry.

Using Freight Calculation

Detailed step-by-step instructions on how to calculate freight from the COP billing screen are in the Global Setup chapter titled Order Billing Screen.

Detailed step-by-step inquiry instructions are in the Inquiry section titled Freight Calculation Inquiry.

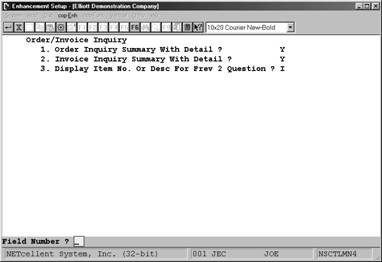

Order Inquiry Setup

Application

Overview

This function gives you fast and easy access to all the necessary information to provide customer service for open or posted orders on file for a customer. It allows you to quickly access and display a customer order using many different lookup options such as Customer P/O number and Ship-To number. You can also view outstanding items ordered by a specific customer, as well as, customers that have ordered a particular item.

Setup Instructions

Select:

Main Menu ® Util-setup ® Global setup ® cop-Ctl ® Order/invoice inquiry. The following screen will appear:

Order Inquiry Setup Screen

Entry Field Descriptions

|

Name |

Description |

|

Order Inquiry Summary With Detail? |

Answer “Y” if you want to view the line item

detail associated with the listed orders.

|

|

Invoice Inquiry Summary With Detail? |

Answer “Y” if you want to view the line item

detail associated with the listed invoices. |

|

Display Item No. or Desc In Detail Section? |

Select “I” or Item Number or “D” for Item

Description. |

NOTE:

This setup also controls the display information for the Invoice History

Inquiry function.

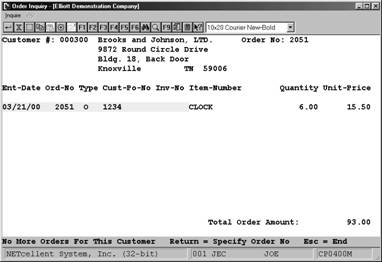

Order Inquiry Window w/Detail

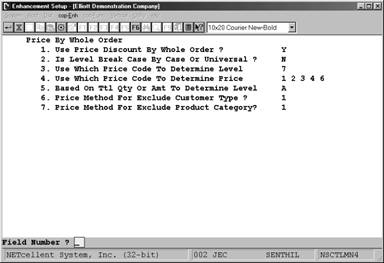

Price By Whole Order

Application Overview

The

standard pricing code method does not provide pricing based on the total sales

order quantity amount or dollar value of the order and the net effective price

of an item is usually determined by the line item quantity. The

Price By Whole Order function is designed for companies who want to price each

item based on the total order quantity, or dollar value. This type of pricing method is used to

encourage customers to buy more when placing an order. The more the customer buys, the better the

discount they will receive. This function also handles pricing based on total

quantity or dollar value of each product category on an order.

Setup Instructions

Go to Elliott Main Menu Util-setup ® Global

setup ®

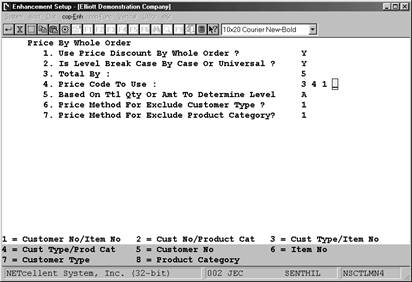

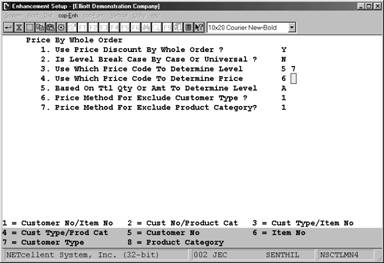

cop-Ctl ® price by Whole order. The following screen will appear:

Entry Field Descriptions

|

NAME |

DESCRIPTION |

|

1. Use Price

Discount By Whole Order |

Select “Y” to enable this function. Select “N” to disable this function. Note:

If you enable this function, the valid price codes defined in the COP

setup are superceded by the price codes defined in this function. |

|

2. Is Level

Break Case By Case Or Universal Level breaks

are defined as the dollar or quantity amounts for an order used as a fixed

reference point. For example:

00-99 = Level Break 1

99-199 = Level Break 2 200-299 = Level Break

3 300+ = Level

Break 4 |

Y

= Level Break is Case by Case Select “Y” if you need different level

breaks for customers or customer

types. N = Universal Select “N” if all

customers or customer types have the same level breaks. |

|

3. Total By: 3. Use Which

Price Code To Determine Level |

If

you answered “Y” for Case by Case

Pricing to question 2, there

are two options: 5 = Total by Whole order - This option

will enable you to use the whole order quantity or amount as the break point

to determine the price level. After

you enter “5”, a popup window will let you define up to 5 Product Categories

that you can exclude from Whole Order Pricing. For Product Categories that you exclude,

you can still define alternate pricing in field 8 of this setup procedure. 8

= Total by Product Category - This option will

enable you to use the total quantity or amount for the line item of the same

product category in an order. If

you answered “N” for Universal Pricing to

question 2, there are five options: 2 = Customer Number/Product Category 4 = Customer Type/Product Category 5 = Customer Number 7 = Customer Type 8

= Product Category Note: Price codes Customer Number/Item Number (1) and

Item Number (6) are not available since it is not practical to

determine an order total level by a single item. If you need these codes and are using the

Universal Pricing Method, disable this function and use the standard pricing

code method. You can define up to

three price codes for this option. If

you choose price code 2, 4, and/or 8, it means that you wish to set the price

discount by product category. If you

choose price code 5 or 7, it means that you wish to set the price discount by

whole order. You cannot use by whole

order and product category together.

For example, if you choose price code 2, the only other two valid

price codes you can choose are 4 and 8.

The system will not allow you to choose 2 and 5 together. |

|

4. Price Code To

Use 4. Use Which

Price Code To Determine Price |

Literal displayed when “Y” for Case By Case in question 2. Literal displayed when ‘N” for Universal in question 2. In

this field, you can use all the standard pricing codes: 1 = Customer Number/Item Number 2 = Customer Number/Product Category 3 = Price Code by Customer Type/Item Number 4 = Customer Type/Product Category 5 = Customer Number 6 = Item Number 7 = Customer Type 8 = Product Category Note: In the pricing

hierarchy, the first price code you enter takes precedence over the latter. |

|

5. Based On Ttl

Qty Or Amt To Determine Level |

A

= Base on Total Amount Q = Base on Total Quantity Your answer here determines how the level breaks

are structured. If the products have similar prices and the

customer only orders 1 each of an item, and you want to encourage this

customer to buy more, you should consider using “Q”, Base on Total

Quantity. If the product’s pricing

varies greatly, the typical order has multiple line items, and each line

item’s quantity is normally greater than one, it would be practical to choose

“A”, Base on Total Amount. |

|

6. Price Method For Excluded Customer Type |

In A/R

Maintenance of the Customer Type file you can exclude customer types from

Price By Whole Order. For excluded

customer Types, you will have the following pricing options: 1 = Price Codes This allows excluded customers to use the valid price

codes defined in COP Setup. 2

= Item Price |

|

7. Price Method

For Excluded Product Category |

If you

excluded product categories in Question 3, Total By Whole Order, you will

have the following pricing options: 1 = Price Codes 2

= Item Price |

|

NOTE: This applies fields 6 & 7 only. |

The “N” Universal method is by far the easiest and fastest

method to setup and maintain because it applies to all customers and customer

types. For this reason it does not

handle pricing code options well for excluded customer types or product

categories. When the Universal method

is selected in this setup, it is recommended that you only use the Item Price

option for excluded customer types and excluded product categories. |

The Price By

Whole Order function is very powerful and sophisticated function. The most critical element of this function is

the setup. To help you better understand

how this function works, we have setup the following three scenarios with Price

By Whole Order Setup examples:

1. Case By Case

Scenario

2. Universal

Scenario

3. Excluded

Customer Type and Product Category Scenario

(This is followed with a How-To process

the order example)

Example I -

Case by Case Method

Company ABC sells

four different items: A100, A200, A300, and B200. They determine the price breaks for each item

based on the total order value. They

also maintain different pricing for two Customer Types, RETL (retailers) and

DLR (dealers). The pricing tables

defined below reflect the pricing structure for each customer type.

Customer

type RETL

|

Item\Value of order |

Base Price |

< $500 |

$500 - $1,000 |

>= $1,000 |

|

A100 |

100 |

100 |

90 |

80 |

|

A200 |

150 |

150 |

135 |

125 |

|

A300 |

55 |

55 |

50 |

45 |

|

B100 |

75 |

75 |

68 |

60 |

Customer type DLR

|

Item\Value of order |

Base Price |

< $500 |

$500 - $1,000 |

>= $1,000 |

|

A100 |

100 |

90 |

81 |

72 |

|

A200 |

150 |

135 |

121 |

112 |

|

A300 |

55 |

49 |

45 |

40 |

|

B100 |

75 |

67 |

61 |

54 |

The “Base Price”

(Selling Price in the Inventory Item Master File) is used to calculate the

total order value and the total order value determines the price breaks. For example, assume that a customer (RETL)

placed an order for 4 A100s and 2 A300s.

Based on the “Base Price” column, the total order value for this order

is calculated as follows:

Standard

Order Processing

4

A100, at $100/EA = $400

2

A300, at $55/EA = $110

Total

$510 (before Price By Whole

Order is calculated)

Customer total

order price break is $500-$1,000

4

A100, at $90/EA = $360 (recalculated value to be billed)

2 A300, at $50/EA = $100

(recalculated value to be billed)

Total $460 (recalculated value to be billed)

This Case By

Case scenario would be set up as follows:

1. Price By Whole Order Setup

NOTE: You may define all 8 Price Codes in field #3. The system will use price codes in the sequence that they were entered.

2. Verify Customer Types are defined in

A/R Maintenance Customer Type File.

3. Verify Inventory Items have a Selling

Price Amount defined. This is done in

Inventory Maintenance - Item File

4.

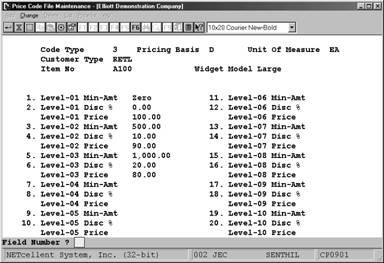

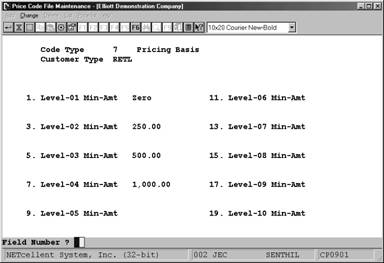

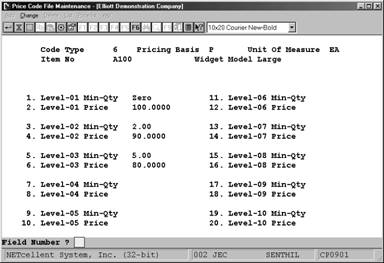

Price Code File Maintenance

Pricing basis for this Price Code is Discount from Base

(Selling) Price, “D”. Other Pricing

basis available are:

M=Markup Percent, P=Price, A=Discount Amount, and U=Markup

amount. Markup from Price or Cost is

defined in the Order Entry Line Item Screen setup.

Price

Code Net Effect: Item A100 for Customer Type RETL

Total

Order Amounts: $0.00 to

$499.99 Discount is 0% Sell Price = $100.00

$500.00 to

$999.99 Discount is 10% Net Sell Price = $ 90.00 $1,000 + Discount is 20% Net Sell Price

= $ 80.00

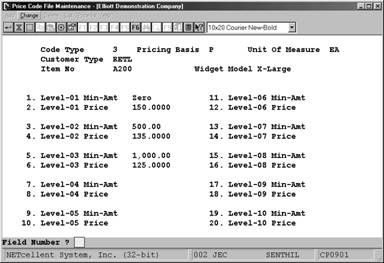

Pricing Basis based on P = Price

Price Code Net Effect: Item A200 for

Customer Type RETL

Total Order Amounts:

$0.00 to $499.99 Sell Price = $150.00

$500.00

to $999.99 Net Sell Price =

$135.00 $1,000 + Net Sell Price = $125.00

NOTE: Each pricing code is unique and you cannot

have Pricing Basis variations for that same

price code. For example:

|

Price Code |

Unique |

Not

Allowed |

Unique

- Allowed |

Unique - Allowed |

|

Type |

3 |

3 |

3 |

3 |

|

Pricing Basis |

Discount |

Price

|

Discount |

Discount |

|

Customer Type |

RETL |

RETL |

DISTR

|

RETL |

|

Item Number |

A100 |

A100 |

A100 |

A200

|

Example

II – Universal Method

This

method has separate levels for the items and customer types.

Table

1: Pricing levels for Customer Types

|

Type\Level |

Price Level 1 |

Price Level 2 |

Price Level 3 |

|

DLR |

<$250 |

$250-$500 |

>=$500 |

|

RETL |

<$500 |

$500-$1,000 |

>=$1,000 |

Table

2: Item Pricing Levels

|

Item\Level |

Base Price |

Level 1 |

Level 2 |

Level 3 |

|

A100 |

100 |

100 |

90 |

80 |

|

A200 |

150 |

150 |

135 |

125 |

|

A300 |

55 |

55 |

50 |

45 |

|

B100 |

75 |

75 |

68 |

60 |

The

advantage of this method over the Case By Case method is the ease of setup,

maintenance and updating pricing changes.

For example:

If we needed to add a

new Customer Type pricing level or revise an existing pricing level, we would

not need to add or revise each item break point as in the Case By Case Method

because all item pricing break points are identical for all customer

types. In essence, we also have

different pricing for customer types by how we define the Customer Type Price

Levels.

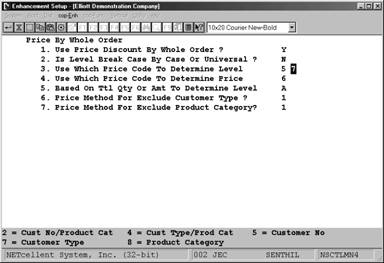

This

Universal Method scenario would be set up as follows:

- Price by

Whole Order Setup

Note: Price Codes 5 & 7 sets the price

discount levels by whole order.

Price Codes 2, 4, and 8 sets the price

discount levels by product category.

In the pricing hierarchy, the system uses Price Codes in the

sequence entered. In our above setup

example, Price Code 5 (Customer Number) would be used first. Price Code 7

(Customer Type) would be used when there is not a Customer

Number Price Code defined for the order customer.

Prices codes may be

categorized as specific and general, and the specific should take precedence

over the general in the sequence entry.

Had we entered the sequence as 7 and 5, then Customer Type (general)

price codes would have priority and for all practical purposes nullify Customer

Number (specific) price codes.

Note: You can use all the eight pricing codes

here. Price Code 6, Item Number, was

selected as the price code to determine the net effective price for the pricing

levels defined in field 3. Although the

system will use the first price code entered, as per the pricing hierarchy, it

did not make sense to add additional price codes in this field since every item

sold has an Item Number.

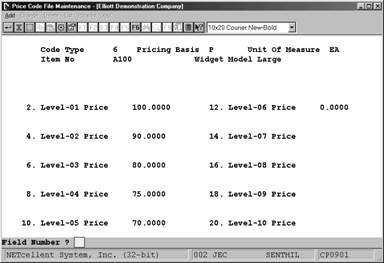

- Define

Price Code for Customer Type RETL

Price Code

Net Effect: Customer Type RETL

Price Level

1 = Total

Order $0.00 to $499.99

Price Level

II = Total

Order $500.00 to $999.99

Price Level

III = Total

Order $1,000.00 +

- Define

Price Code for Customer Type RETL

Price Level 1 = Total Order

$0.00 to $249.99

Price Level

II = Total

Order $250.00 to $499.99

Price Level

III = Total

Order $500.00 +

- Setup

Item Price Codes

Note: Item A100 has 5 levels that determine the

price. This is to accommodate another

customer type that has 5 price levels for total order amount. This is the ease

and speed of setting up price codes using the Universal Method; the same price

for all customers, but what determines the net effective price to use is the

total order level setup in the Customer Type Price Levels.

Example III

-Case By Case Method with Excluded Customer Type

and Excluded Product Category

American

Window Films, Inc. (AWFI) sells

window tinting film to their dealer channels (mostly jobbers). AWFI has a competitor who sells to the same

dealer channels. AWFI’s dealers normally

order one roll of film whenever they have an installation to do. AWFI would like to encourage the dealers to

order more by offering quantity discounts based on the order quantity

total. This will help AWFI compete

against other competitors. The following pricing tables were defined by AWFI:

Price

Table for Customer Type JOB1, JOB2,

JOB3, JOB4 and JOB5

|

Item\Level Brk |

Base |

Qty = 1 |

Qty = 2 to 4 |

Qty >= 5 |

|

A100 |

100 |

100 |

90 |

80 |

|

A200 |

150 |

150 |

135 |

125 |

|

A300 |

55 |

55 |

50 |

45 |

|

B200 |

2 |

2 |

2 |

2 |

Item B200 is an

accessory with a small unit price and a large quantity. They do not wish to

give discounts to item B200.

Furthermore, they do not wish to include item B200 quantities for

calculating the order’s discount. The

product category for Item B200 is ACR.

AWFI

also offers price discounts for their key dealers. The following pricing table

was defined for their dealers (Customer type KEY):

Price

Table for Customer Type KEY

|

Item\Level Brk |

Base |

Qty = 1 |

Qty >2 |

|

A100 |

100 |

90 |

80 |

|

A200 |

150 |

135 |

125 |

|

A300 |

55 |

50 |

45 |

|

B200 |

2 |

1.5 |

1.5 |

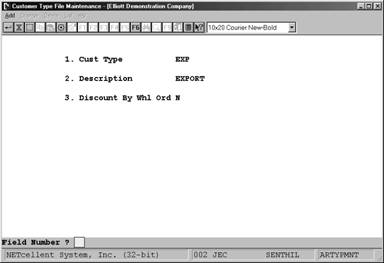

AWFI

also exports their films to foreign countries.

When they export, they do not wish to use price discount by whole order.

Each export customer has a special negotiated price for each individual

item. For export customers, the customer

type is EXP.

This

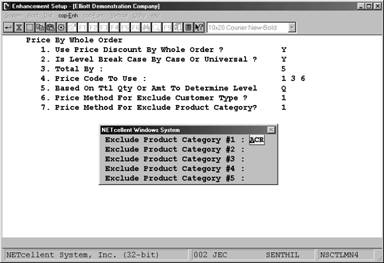

Case-By-Case scenario with excluded Customer Types and Product Categories would

be setup as follows:

1. Price by Whole Order Setup

Note: Field 3

If option 5

(Total By Whole Order) is selected, you can define up to five product

categories to exclude from Price By Whole Order.

Field 4

Price Codes selected:

1

= Customer Number/Item Number

3

= Customer Type/Item Number

6

= Item Number

Field 5

Q = Base On total Quantity selected as basis to determine Levels

2.

Verify in A/R Maintenance Customer

Type File that Customer Type EXP does not use Price By Whole Order

Note: Field 3

The choices here are “Y” = Yes and “N”

= No. The default value is “Y” and if

this field is left blank, it accepts “Y” as the default. For this reason, if you want to exclude a

customer from Price By Whole Order you must enter “N” in this field.

- Set Up

Price Codes 1, 3, and 6.

Code 1: Customer No./Item No. for Export Customers

Each export

customer has a special negotiated price for each item and do not use Price By

Whole Order pricing.

Code 3: Customer Type/Item No. for Customer Type Key

Code 6: Item

No. for All Other Customers, (JOB1 – JOB5)

In the pricing hierarchy, customers who are not

excluded, (Type EXP), and who are not Key type customers will receive this

pricing based on total order quantity.

This code then fits customers who we want to encourage to buy more by

offering quantity discounts based on the total order quantity.

Price Code 6 Setup for Item A100

NOTE: The “Min-Qty” applies to the whole order

quantity. In this particular scenario, the whole order quantity includes items

A100, A200, and A300. If order has 2 ea.

A100, 2 ea. A200, and 1 ea. A300, the total order quantity would be 5; the customer would pay $90.00 for Item A100,

and the respective Level 03 Prices for Item A200 and A300.

Using Price

By Order

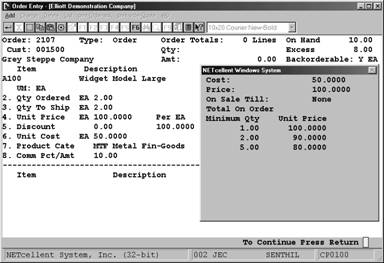

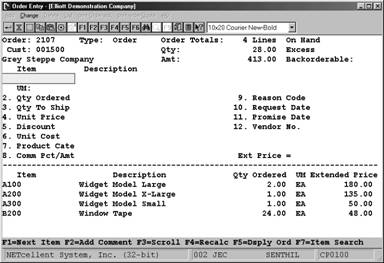

In this order entry example,

we will be using the Case By Case method, pricing by whole order, and the break

levels are based on quantity. These are

the same defaults defined for Example III, American Window Films, Inc.

The above figure shows that we have entered 2 ea. A100,

the Unit Price is $100.00, but the Price Break Popup window (F7 Key) shows that

if our total order quantity is 2, the price should be $90.00. This is because we must recalculate the order

using the F4 Key to reflect the discount pricing. This is done after you have completed the

line item entry. If you have not

recalculated your order after you complete all line entry items, the system

will do it automatically when you exit the line item screen and go to the billing

screen.

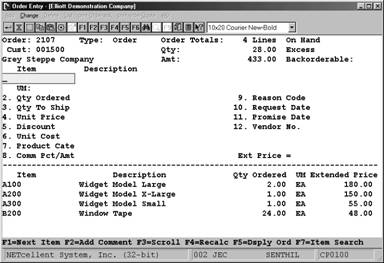

We will recalculate this line item, enter a few more

items, and then show you an example of how to recalculate an order.

The order now has 4 line items and a total quantity

of 28 ea. This information is displayed

in the upper right portion of the line item entry screen. In the lower section of the screen, we see

that Item A200 does not reflect total order quantity pricing, nor does Item

A300. Since we have not recalculated

after completing the line item entry for Item A100, we cannot be sure if this

is the right price or not. It is

important, especially if you are on the telephone with your customer, that you

recalculate after each line item entry to know the correct selling price. It is equally important that you use the F7

Key to be aware of the break levels so that you recommend to your customers

that they bump their order to get a better price.

Recalculation is simple, easy, and very

straightforward. All it requires is

pressing the F4 Key after completing a line item entry. For this example, we will recalculated and

show you the net effect on the next page.

Order recalculated and Items A200 and A300 now

reflect the 2 to 4 quantity discount pricing.

The system did not use the quantity for B200 in the recalculation

because B200 is product category ACR which we excluded from Price By Order.

Price List by Customer

Application Overview

This enhancement is an improved price list from Elliott’s

original design. It provides an easier way to read a customer(s) price

list. You can locate an item price for

a customer more quickly, and this list can be sent to a customer(s) with more

concise information. This enhanced list

can be sorted by Item Number, Product Category, User Defined Code, and

Warehouse Location, etc.

Run Instructions

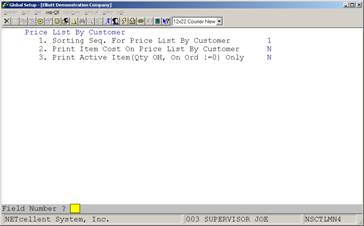

Elliott Main Menu à Util setup à

Global setup à

cop-ctl à

Price list by customer

Figure 4G.1 shows the setup screen for Price List by Customer.

Using Price List by Customer

1.

Select Distribution form the Elliott Main Menu.

2.

Select Customer order processing.

3.

Select Maintenance.

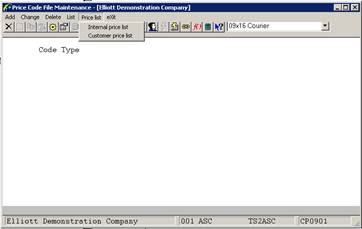

- Select

Price code file.

- Select Price list.

Options to Generate

Internal (House Use) or Customer

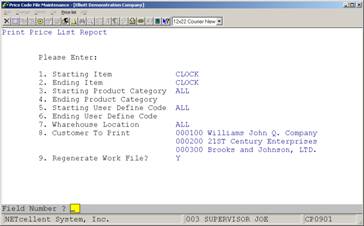

Example of how to generate the Price List by Customer.

|

Run Date: Oct 31, 2001 - 10:33pm Elliott Demonstration Company Page 1

P

R I C E L I S T B

Y C U S T O M E R

Ranges: Item CLOCK Thru CLOCK All

Product Categories

All

Locations

Customer 000100 Williams John Q. Company 000200 21ST Century Enterprises 000300 Brooks and Johnson, LTD.

Product Category A Raw Material

Us Item-Number

Item-Desc

Um Price Price Price Cd

Cust 000100 Cust 000200 Cust 000300

Type

DISTR Type RETL Type DISTR

Product Category A Raw Material

CLOCK 25 Meg Clock For

Mother Board EA 15.50 15.50 15.50 |

Internal price list

showing the pricing information on a specific item for three different

customers.

Print COD Tag

Application Overview

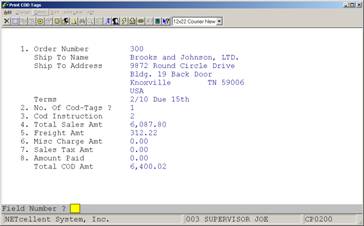

This enhancement gives users the ability to print one or multiple COD tags for an order number. Note: This enhancement only prints a COD tag for order type "O" or "I". The enhancement has the capability of printing either the customer number, plus the order number plus the box number as the alternate control number, or the customer number plus the invoice number plus the box number as the alternate control number.

This enhancement allows users to print COD tags under two environments. One environment is the one-step COD tag. This is the case where the order is taken, a picking ticket is printed, all items are picked and ready to be shipped, and finally COD tags are selected to be printed for warehouse. The disadvantage of this environment is that the total amount is not saved, freight amount has not been determined, and the invoice number is not available. Under this environment, the user cannot use the invoice number as part of the alternate control number since no invoice number exists.

The enhancement has the capability of printing the UPS shipper number. In order for this to be done, the user must set the UPS shipper number in the Global Setup.

If the order is not selected for billing, this enhancement will calculate the total sales amount and sales tax amount. The user can override these amounts. If the order is selected for billing or the order invoice is printed, then total sales, freight, miscellaneous, and sales tax amounts are available. The enhancement will display these amounts, but the user cannot override them.

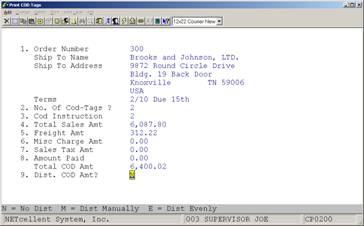

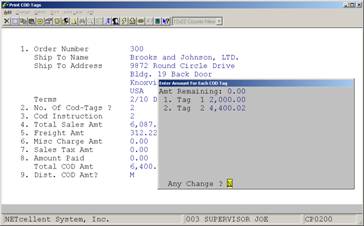

The enhancement will calculate the total COD amount after all amounts are calculated. The user can enter how many tags are to be printed. Next, the user enters if the payment should be cash only or not. Finally, the user must decide whether the total COD amount is to be distributed or not distributed among the COD tags.

This enhancement provides protection for orders that are not COD's. If the terms code description is not "COD" or "C.O.D.", then a warning message will appear asking if the user wants to continue. If the answer is "yes", the user can then enter the rest of the information. If the answer is "no", then the user can select another order number.

For cash-only orders, the enhancement will mark the cash-only box on the COD ticket. This box will be marked when the user answers "yes" for the question "Cash Only" or when the terms code description includes the word "CASH" or "Cash". If the box is not marked, the instruction will be "Company Check OK".

Run Instructions

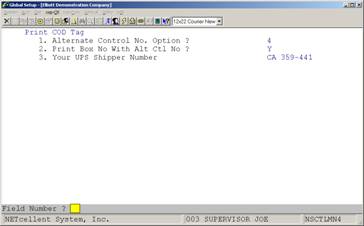

Elliott Main Menu à Util setup à Global setup à cop-Ctl à print cod Tag

Figure 4H.1 shows the setup screen for Printing COD Tags.

Field Entry Descriptions

1. Alternate Control No. Option?

This flag is very important. This information will be used internally to reference back to the order. When you receive the check from UPS, it will have this alternate control Number which can be used to determine what order it was for. There are 5 options: 1 = Cust No, 2 = Order Number, 3 = Invoice Number, 4 = Cust Number + Order Number, & 5 = Customer Number + Invoice Number.

2.

Print Box No. With Alternate Control

Number?

If you answer “Y” to this question, the system will print box numbers with the alternate control number.

3.

Your UPS Shipper Number

Enter your UPS shipper number. This information will print on the COD tag.

Using Printing COD Enhancement

The user

has two options of applying the total COD amount. The first option is to print only 1 tag, Field

2. This will print the total COD amount on one COD tag and as a result, 1 COD

tag per order.

Generate COD Tags

Key Field Entry Description

Field 3: Determines

how COD is to be paid.

0 = No

instructions

1 = Certified

Check/Money Order

2 = Company

Check

The second option is to print more that one COD tag per order. If the user selects this option, then the system adds Field 9 to the screen. This field prompts the user on how they want to distribute the COD amount. The choices are:

1. N = No Distribution. Total amount goes to 1 tag.

2. M = Manually Manually distribute the COD amt. to the number of tags printed.

3. E = Dist. Evenly System will distribute COD amt. evenly to the number of tags.

If M=Manually is selected, a window will pop up and the user can enter an amount for each COD tag. After an amount is entered, the projected total COD amount remaining will be displayed. See figure next page.

Credit Check & Release

Application Overview

This

function allows you to put an order on hold and release a held order based on

two criteria: 1) Customers exceed the credit limit, or 2) Customers have a past

due amount. It also allows selected A/R

term codes, customers, and customer types to be exempt from this automatic

credit checking procedure. If a

customer’s account meets one of these two hold criteria, the order will be put

on hold automatically. If needed, only

authorized persons such as credit managers or supervisors can be allowed to

release an On-Hold order. This release

can be done through COP Order Entry or a special separate Release function,

which provides additional credit information for the credit manager or

supervisor to review before releasing an order.

Run Instructions

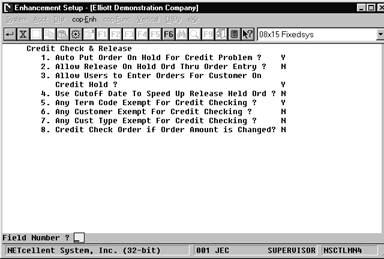

Go to Elliott Main menu: Util-setup ® Global setup ® cop-Ctl ® credit check & Release. The following screen will appear:

Entry Field Descriptions

|

Name |

Type and Description |

|

1. Auto Put Order On hold for Credit Problem |

Select

“Y” to enable this function. If

enabled, a popup window appears and this is where you define the following

credit checking criteria: 1.

Customer has exceeded his credit limit? Select

“Y” Or “N” 2.

Customers actual aged account balance for

Period 1 is greater than xxx, xxx.xx (user specified amount). 3.

Customers acutal aged account balance for

Period 2 is greater than xxx, xxx.xx (user specified amount). 4.

Customers acutal aged account balance for

Period 3 is greater than xxx, xxx.xx (user specified amount). 5.

Customers acutal aged account balance for

Period 4 is greater than xxx, xxx.xx (user specified amount). If field 1 is “Y”, then any orders matching these

criteria will be put on-hold. If an

order exceeds any of the user-specified amounts in fields 2 – 5, that order

will be put on-hold. |

|

2. Allow

Release On Hold Ord Thru Order Entry |

Select “Y” to allow the user to release this order

during order entry. If “N” is selected,

then orders can only be released using the Release Held Order menu

function. This menu function can be

password protected for a supervisor or Credit manager. |

|

3. Allow Users

To Enter Orders for Customer On Credit

Hold |

“Y” or “N” is dependent on your credit hold policy. |

|

4. Use Cutoff Date To Speed Up Release Ord |

This question applies to the Release Held Order menu

function. When you release held orders, the system will read the entire order

header file and display all held orders.

If you do not wish to display all, select “Y” to specify a cutoff date

option. The cutoff date options to

select from are “S” = System Date or

“E” = Earliest Date “ |

|

5. Any Term Code

Exempt For Credit Checking |

Select “Y” to define up to 5 Terms Codes, (popup

window), that will exempt from Credit Checking. Select “N” for no exceptions. |

|

6. Any Customer

Exempt For Credit Checking |

Select “Y” to define up to 5 Customers, (popup window),

that will exempt from Credit Checking.

Select “N” for no exceptions. |

|

7. Any Cust Type

Exempt For Credit Checking |

Select “Y” to define up to 5 Customer types, (popup

window), that will exempt from Credit Checking. Select “N” for no exceptions. |

|

8. Credit Check

Order If Order Amount Changed |

After an On-Hold order has been approved and released,

the system does not perform additional credit checks when the order is

changed. This is a convenience factor

to reflect changes in terms, shipping instructions, salesmen, etc. However, this presents a potential loophole

where the customer or salesman can substantially increase an approved

credit-risk order and escape a second credit check. Select “Y” to close this loophole by having

the system do credit checking anytime the order dollar amount has been

changed. |

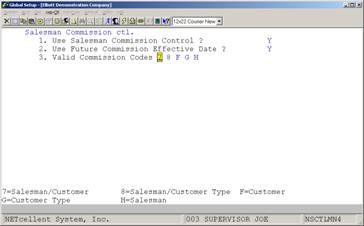

Sales Commission Control

Application Overview

This

function will provide you with a very flexible method of defining sales

commissions. It is similar to the

Elliott Pricing Structure. You can predefine as many commission codes as you need

and specify an effective date for the sales commission. With 17 different commission codes to choose

from and 10 levels for break points, this function will allow you to define

almost any kind of commission.

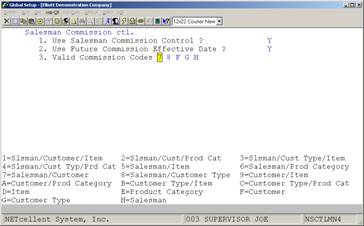

Run Instructions

Elliott

Main Menu à Util-Setup à Global Setup

– cop-Ctl à Sales

commission Ctrl

Commission Codes Available when COP

Setup Calc Commissions = I (Item)

Commission Codes Available when COP

Setup Calc Commissions = S (Sales)

Commission Codes Available when COP

Setup Calc Commissions = M (Margin)

Field Entry Descriptions

- Use Salesman Commission Control?

Select “Y” to enable. If not enabled, “N”, the system will base commissions on the default value in COP Setup.

- Use Future Commission Effective Date”?

If “Y”, allows you to specify a Starting and Ending date, (if applicable), for a commission code.

- Valid Commission Codes

Determines which codes will be available in COP Commission Structure File.

User Defined Code Setup

Application Overview

This

feature gives you the ability to assign a “User-Defined Code” in the COP line

item screen for special tracking purposes.

In the Order Line Item Entry Screen, the system will prompt you to enter

a User-Defined Code. You can either

press enter to skip this field or enter a valid code (F7 search key is

provided). When posting invoices to A/R,

the system will update COP Invoice History, User Defined Code/Year, and

Customer User Defined Code/Year Files.

This information can be used later for reporting and analysis

purposes. We have also provided an

initialize, export, import, and rebuild function for these three files.

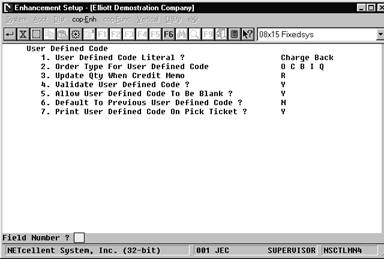

Run Instructions

Before setting up User Defined Codes. You must define what, where, and

how you want to use them. To do this, go

to:

Main Menu ® Util-setup ® Global setup ® cop-Ctl ® User defined code. The

following setup screen will then be displayed:

User Defined Code Setup Screen

Entry Field Descriptions

|

Name |

Type and

Description |

|

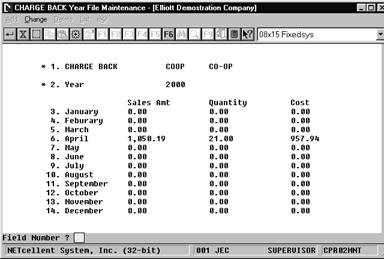

1. User Defined

Code Literal |

This

question prompts you for the field literal that will display in the COP line

item screen. For example purposes, the

literal “CHARGE BACK” is used |

|

2. Order Type

For User Defined Code. |

You

can select the type of orders that will display the line item user defined

code, “CHARGE BACK”. There are five options displayed at the bottom of the

screen. You can press <Enter> to

select ALL. |

|

3. Update

Quantity When Credit Memo |

If

you want to return item qty. back to inventory, enter “R”. If you want to give the customer a qty.

credit, enter “C”. This option only

applies to credit memos. |

|

4. Validate User Defined Code |

Answer

“Y” to validate the User Defined code when entered in COP Line Item screen. |

|

5. Allow User

Defined Code To Be blank |

Answer “Y” to allow users to enter a blank value. |

|

6. Default To

Previous User Defined Code |

If

you answer “Y” to this question, the system will use the code entered in the

last order. |

|

7. Print User

Defined Code On Picking Ticket |

Answer

“Y” to enable this function. |

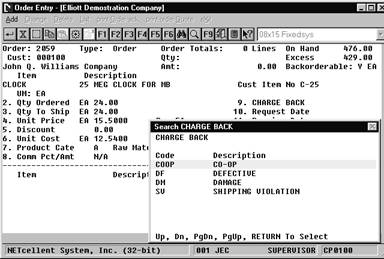

Using

User Defined Code

After

enabling this function, you will need to define the “Charge Back” codes using

the User-Defined Code file maintenance.

To do this, go to:

Customer Order

Processing ® Maintenance ® User defined code file

The

screen that appears is where you define your codes, as well as the change,

delete, and list functions. Some

examples of user defined codes are COOP Advertising, Damaged Goods, Defective

Merchandise, Direct Mail Sales, Telemarketing Sales, etc. With careful planning and forethought to user

defined codes, these codes can be powerful reporting and analytical tools.

After

defining your “Charge Back User Defined Codes” (Charge Back is just a literal

expression) and you enter an order type as defined in the setup, the line item

screen will display a “CHARGE BACK” for your input. At this field, we have provided an F7 key

function to search for your codes. After

posting invoices to A/R, the system will update the User-Defined Code/Year file

and the Customer User Defined Code/Year file.

These are the two files used for reporting and analysis.

Charge

Back field 9 and F7 popup Search window display.

The

User-Defined Code/Year file is

divided into 12-month buckets. It

displays the Sales Amount, Quantity, and Cost.

You can print a listing based on a “CHARGE BACK” (user-defined) range

and year range. This information can be

used as an analysis tool.

To

access this file: Customer Order Processing ® Yearly

user defined file.

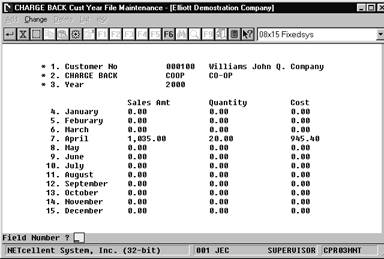

The

Customer User-Defined Code/Year file

is divided into 12- month buckets. This

file is similar to the User-Defined Code/Year file. The only difference is that you can display

information for a specific customer. It

displays the Sales Amount, Quantity, and Cost.

You can print a listing based on a customer range, “CHARGE BACK” (user-defined)

range and year range. This information can be used as an analysis tool.

To

access this file: Customer

Order Processing ® yearly cust user Def code.

User-Defined Code Year/File

Maintenance Screen

Customer User-Defined Code/Year

File Maintenance Screen

Stock Status Inquiry Setup

Application Overview

This function provides you with a wealth of customer service information

available by using Function Keys. For

maximum benefit, the users should thoroughly familiarize themselves with the

many item inquiry options. These

features are also available in our Sales Desk program.

The COP Stock

Status Inquiry provides for a Customer Number so that when you do an item

inquiry for that customer, you have access to pertinent A/R, I/M, and COP

data. Some key features found in this

program are:

1. Item

inquiries listing one or all locations where an item is stocked. Also included in the item inquiry are

stocking totals and Bin numbers. Being

able to view stock status by all locations is extremely useful when you ship from

different locations or have the need to transfer from one location to

another. It is also helpful when you

have multi locations within your warehouse, (refurbished items, returned goods

for resale, factory seconds, inspection, quarantine, etc.), to view stock

status totals for that item.

2. Ability to use wildcards to specify the

locations you wish to see stock statuses for.

3. The option to enter a caller’s name. This helps the user in remembering who they

are talking to, as well as, logging the persons name for future reference.

4. After you have entered the customer’s number

for an inquiry, and if no caller name was entered, then the caller name will be

automatically filled with this customer’s contact name.

5. While you are viewing an item’s stock status,

you have the following added functions:

a.

View customer price breaks for this customer and item.

b.

Create a quote from the customer’s inquiry.

c.

Create a sales order from the quote.

b. View general customer information for the

customer.

c. View credit & YTD information for the

customer.

d.

Perform a Substitute Item Search by location

e.

Perform a Component Available Inquiry to show the stock

statuses of all components for a parent item to determine the quantity of the

parent that can be built.

f. Perform

an Available To Promise Inquiry to

display a listing of future quantity available, (by date), for the

inventory item being viewed.

Run

Instructions

SELECT:

Main Menu ® Util-setup ® Global setup ® cop-Ctl ® Order/invoice inquiry. The following screen will appear:

Stock Status

Setup Screen

Note: The setup default values affect both COP and I/M

Entry

Field Descriptions

|

Name |

Description |

|

Use

Quotation In Stock Status Inquiry |

Select “Y” to create a Quote from an inquiry. When you create the quote, you have the

option to confirm it. If confirmed,

the system will allow you to enter a COP sales order for this quote during

stock status inquiry. If not

confirmed, these quotes are kept in the Quotation History file and can be

called up for review, and/or converted to an “O” or “I” type order. Select “N” if you do not want users

creating sales orders from this inquiry mode. Note: If you find yourself becoming a power user

of quotes using the Stock Status Inquiry screen; we recommend you use our

Sales Desk program for tighter quote management and more flexible features. |

|

Starting

Quotation Number |

Enter Starting Quote Number, this is an

internal number used in Stock Status Inquiry and not related to COP Quote

numbers |

|

Use

Quotation Comment |

Select “Y” if you want

to add comments to your quotes.

Comment codes are maintained in COP maintenance. Quotation comments are mainly for used

historical sales analysis purposes to track the reasons why you don’t get a

sale from a quote. |

|

Default

Quotation Comment Code |

If you the enable the previous field, then

you may specify the default comment code here. Comment codes are maintained in COP

maintenance. |

|

Use

Inquiry Comment |

Select “Y” if you want to add comments to

your inquiry |

|

Default

Inquiry Comment Code |

If you enabled the previous field, then you can specify the default

comment code here. |

|

Update

Quotation History For Inquiry Trx |

Select “Y” to keep a history of caller inquires in the Quotation

History file. The Inquiry Trx’s will then show up when doing a quote

inquiry. |

Sales Desk

Application Overview

Sales Desk is

a powerful program that can greatly improve the speed and efficiency of

processing orders, quotes, capturing new business, and building customer relationships. After setting up Sales Desk, you should set

up a Procedures and Policy guideline for COP sales entry personnel and Sales

Desk users. Many of these procedures and

policies can be defined in Sales Desk setup.

Sales Desk does not currently support the following:

- Vertex Sales Tax Interface

- “I” and “C” type of Orders for Serial/Lot and Multi-Bins

- Feature/Option & Kit items.

Run Instructions

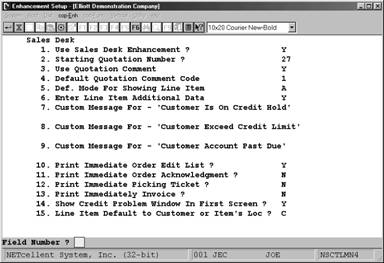

Goto: Elliott Main Menu à Util Setup à Global setup à cop-ctl à sales Desk

Sales Desk Setup Screen

1. Use

Sales Desk Enhancement?

Select “Y” to enable this feature.

2. Starting Quotation Number?

Enter starting quote number. This number is used only in Sales Desk and

does not affect COP orders. The default

value is “1”.

3. Use Quotation Comment?

Default value is “N”. Select “Y” if you want to add comments to your quotes. Comment codes are maintained in COP maintenance. Quotation comments are mostly used for historical and sales analysis purposes to track reasons why you did not get a sale for the quote.

4. Default Quotation Comment Code

The default value is blank. If you enabled the previous field, then you can specify the default comment code here. Comment codes are maintained in COP maintenance.

5. Def. Mode For Showing Line Item

When

entering line items in Sales Desk, you have the choice of confirming the line

tem or leaving it open as a quote. This

flag lets you choose if you want to view all the line items as you are entering the order, or only the confirmed

items. Confirmed items are those that get generated onto the sales order. This is a default mode only and the system

allows changing from mode to mode during data entry.

Select “A” for Show All, or “C” for Show

confirmed items only.

6. Enter Line Item Additional Data

Additional Data Window contains line item discount percent, unit cost,

vendor number, product category, user defined code, and request and promise

dates. These are fields from Elliott

order entry line item screens. Most of

the time, you simply accept the default values for these fields in the order

line item screen. If this is the case,

you should answer “N” and this will speed up your process in Sales Desk. If you need to enter data in any one of those

fields, answer “Y” and during entering of line item in Sales Desk, the

additional data window will popup and prompt for the information.

7. Custom Message For - 'Customer Is On Credit

Hold'

By default “Customer Is On Credit Hold” will be displayed if Sales Desk

detects such a condition. Even though a

customer may be put on credit hold, you may not want the customer to know they

are on credit hold. To prevent your

staffs from telling customers that they are on “Credit Hold”, you can put a

custom message here. If you leave this

field blank, the system will use the default message.

8. Custom Message For - 'Customer Exceed

Credit Limit'

Similar to previous field, to prevent your staff from telling customers

they “exceed credit limit”, you can put a custom message here.

9. Custom Message For - 'Customer Account

Past Due'

Similar to previous field, to prevent your staff from telling customers

that their “account is past due”, you can put a custom message here.

10. Print Immediate

Order Edit List?

Select “Y” if you want to print an immediate order edit list when an

order is entered through Sales Desk.

Select “N” to disable this feature in Sales Desk if you wish to manually

print order edit list in Order Entry.

11. Print Immediate

Order Acknowledgment?

Select “Y” to immediately print an Order Acknowledgement when an order is

entered through Sales Desk. Select “N”

to disable this feature in Sales Desk if you wish to manually print Order

Acknowledgement in Order Entry.

12. Print Immediate Picking Ticket?

Select “Y” to immediately print a Picking Ticket when an order is entered

through Sales Desk. This is helpful if

the order needs to be picked right away and pick tickets are printed on an

individual basis. Select “N” to disable

this feature in Sales Desk if pick ticket is printed on the batch basis.

13. Print Immediately Invoice?

Select “Y” to immediately print an Invoice for an “I” type of order

entered through Sales Desk. This may be

helpful for over the counter sales, or if you use the invoice as a pick

ticket. Select “N” to disable this

feature if invoices are printed on a batch basis.

14. Show Credit Problem Window In First

Screen?

Select “Y” if you want Sales Desk people to be made aware of the customer

credit status before entering an order.

If you select “N”, a credit problem window will still come up when you

confirm the order. If you want to get

order first and worry about the credit problem later, you should answer

“N”. Otherwise, answer “Y”.

15. Line Item

Default to Customer or Item's Loc ?

This flag is only relevant if you use the multiple locations feature in Elliott. By default, system default s a line item’s location to customer’s default location.

If you are a distributor who stocks inventory at all warehouse, then this is the right choice for you.

If you are a manufacturer producing produce and stocking items at different locations, then you should default line item’s location by item’s default location (as setup in the item master record).

Select “C” for customer default location or “I” for item default location. This is a default value and the actual line item location can be changed at line entry time.