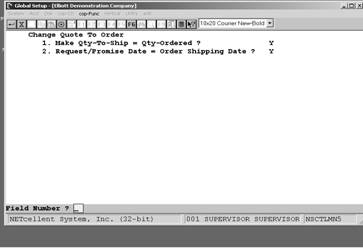

This function will allow you

to change a quote to an order. It will also let you set the Request/Promise

Date to equal the Order Shipping Date? You can only change a quote to a “O”

type order.

Note: If you have an old order that you wish to copy to a

quote, you can use the copy order function under COP Processing.

Run Instructions

Elliott Main Menu à Util

setup à Global setup à cop Func à Change quote to order

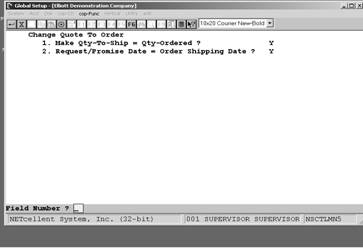

Figure 5A.1 shows the setup

screen for Change Quote To Order.

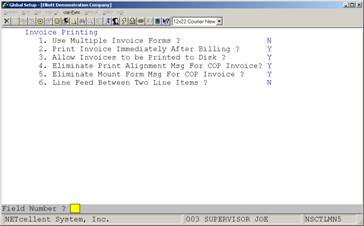

The purpose of this function

is to provide additional invoice printing features.

1.

It allows you set up a default

invoice form for a specific customer in the customer file. When you print

invoice(s) for this specific customer, the system will use the invoice form

defined in the customer file and not COP setup.

2.

It will allow you to print an

invoice immediately after billing an order.

3.

It will allow you to print

invoice(s) to disk.

4.

It will eliminate the print

alignment message before invoice printing.

5.

It will eliminate the mount form

message before invoice printing.

Elliot Main Menu à

Util setup à Global control à cop-Func à

Invoice printing

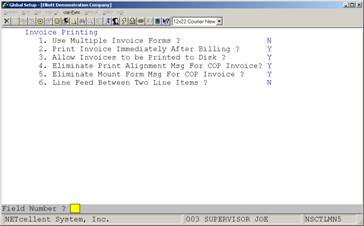

Figure 5B.1 shows the setup screen for Invoice

Printing.

Elliott

COP is a feature rich module with many features and functions that are

controlled in the Order Header, Order Line Item, and Order Billing Screens.

Rather than enabling these features and functions that may not apply to all

users, we give the user the option to select only those that apply to them or

that they can use to better meet their needs and functionality. The COP

managers or owners should review the options available with management and COP

users, and then incorporate the options selected into their Procedures and

Policies Manual.

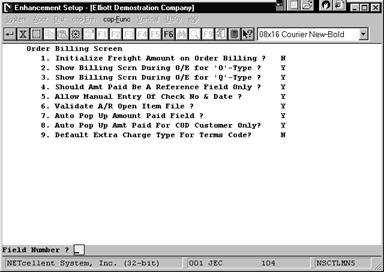

Go to Elliott Main Menu: Util-setup

®

Global Setup ® cop-Func ® order Billing

screen. The following setup screen will appear:

Entry Field Descriptions

|

NAME

|

DESCRIPTION

|

|

1. Initialize

Freight Amount on Order Billing?

|

The purpose

of this function is to pull-in the freight amount from a Manifest System

(Starship).

|

|

2.

3.

4.

5.

6.

7.

8.

|

Flags 2, 2-8

are related to the Deposit Handling Enhancement. Flag these functions as “Y”

and do their set up using the Deposit Handling documentation that follows.

|

|

9. Default

Extra Charges For Terms Code?

|

This is only

a default field. The Terms Code function allows you to add an extra charge

to an order by a set dollar amount or percent. Select “A” for dollar amount,

“P” for Percent, or “N for none.

|

Standard Processing Method

The standard method of

order entry is designed to enter, process, ship and invoice orders. It is not

designed to apply deposits, pre-payments, or credit memos to all type of orders

in COP. To enter a deposit or pre-payment, the user usually receives posts the

deposit in A/R Cash Receipts and applies it as an Open Credit to the customer.

The Standard Processing Method does provide the function to apply an “Amount

Paid” to COP type “I” orders. This works reasonably well if the invoice is

immediate or an over the counter sale.

When a

Standard Method COP type “O” order is selected to bill and the invoice printed,

the printed invoice will show the entire invoice amount as the Balance Due even

though the customer has a deposit, pre-payment, or credit memo against this

invoice. To lessen any misunderstandings with the customer and his invoice,

the deposit could be referenced in the Invoice comments.

After the invoice has been

posted, the COP user must go to A/R and Reapply the open credit to the

invoice. If they are not authorized for this A/R process, they must notify the

A/R user and explain the situation. Until the Open credit has been reapplied

to the invoice, the invoice remains open and is reflected as such in the

customer credit history and financial status.

From a centralized cash

receipts process and cash management standpoint, the following are areas of

concern with the Standard Processing Method:

1. Cash receipts and A/R are not updated until the

invoice is posted.

2. If invoice originated as an order, do you withhold

processing any “Amount Paid” until the order is filled, shipped, and ready to

invoice? Or, do you post payment as an open credit and reapply after the order

has been invoiced and posted?

3.

Who handles cash, the A/R

Department or Sales Processing Department?

NOTE: For

terminology purposes, Deposit is synonymous with cash received, cash applied,

partial payment, and pre-payment.

Deposit Handling Method

The

Deposit Handling Method resolves all the Standard Method Process issues by

posting deposits as an open credit in A/R and linking them, automatically or

via a popup window, to the COP Amount Paid field. Additionally, it gives you

the controls to establish a centralized cash receipts process.

Go to Elliott Main Menu: Util-setup

®

Global setup ® cop-Func ® order Billing screen. The following setup screen

will appear:

Entry Field Descriptions

|

NAME

|

DESCRIPTION

|

|

1. Initialize

Freight Amount On Order Billing?

|

Does

not apply to deposit handling.

|

|

2. Show

Billing Scrn During COP For “O” Type Orders?

|

Answer

“Y” if you want Sales Order Entry people to access billing screen to enter

payments, freight, miscellaneous charges or comments at order entry time for

“O” type orders. Answer “N” to use the Standard Processing Method.

|

|

3. Show

Billing Scrn During O/E For “Q” Type Orders?

|

Answer

“Y” if you want Sales Order Entry people to access billing screen to enter

payments, freight, miscellaneous charges or comments at order entry time for

“Q” type orders. Answer “N” if you do not need these features for “Q” type

orders.

|

|

4. Should

Amt Paid Be a Reference Field Only?

|

If

you answer “N”, Deposit Handling will be disabled and the cash receipts

processing will use The Standard Processing Method.

Answer

“Y” to enable Deposit Handling. If flagged “Y”, the Amount Paid on the

Billing Screen for “O” and “I” type orders will not post as a cash receipt.

However, and since the system is using payments/open credits from A/R to

populate this field, the printed invoice will reflect the correct Balance Due

amount. Upon posting the invoice, the system will Re-Apply the payment/open

credit to the posted invoice.

|

|

5. Allow

Manual Entry of Check No. and Date?

|

If

answered “N”, a window will popup allowing you to define up to 5 Supervisors

(users) who can manually enter a Check No. and Date. This is a security

feature to ensure data accuracy and only let the designated supervisors make

adjustments when a situation exists outside normal operating procedures.

However, non-supervisor users can still use the F3 Key to select the Open

Payment amount and automatically populate the Check No. and Date fields with

the values of the Payment/Credit.

Answers

“Y” to let all users manually enter Check No. and Date.

|

|

6. Validate

A/R Open Item File?

|

This

flag defaults to “Y” and cannot be changed if you said “N” to allow Manual

Entry of Check No. and Date, (Field 5, above). If “Y” to allow Manual entry

of Check No. and Date, the Deposit Handling s function gives you three

options:

1.

Y=Yes 2. W=Warning 3. N=No.

If

“Y”, the system will validate the check number and date in the A/R Open Item

file. If it cannot validate the Check No. and Date, it will not

accept the information entered and will prompt you for a valid Check No. and

Date.

If

“W”, the system will issue a Warning Message, but let you proceed with the

Check No. and Date as entered.

If

“N”, the system will not validate and accept the Check No. and Date as

entered.

Note: These

same options and rules apply if you are processing an open credit memo

against an order.

|

|

7. Auto

Pop Up Amt Paid Field?

|

This

function will automatically populate the Amount Paid, Check No., and Date

fields for a Credit Balance Customer with their open payment or credit memo.

Answer “Y” to enable this function. Auto Pop Up will only work for Credit

Balance Customers.

The

system only allows one open payment/credit to apply per invoice and if the

customer has more than 1 Open Payment/Credit the system will display a

message saying “Multiple Unapplied A/R Open Item Records Exist.” However,

you can still apply multiple credits per invoice using the procedures

detailed in the Processing Order Entry section of this manual.

|

|

8. Auto

Pop Up Amt Paid For COD Customer?

|

This

is the same function as flag #7, but for COD Customer only. If you select

“Y” for this function, it overrides and disables flag #7 if it was answered

“Y.” This enhancement only works for customers with COD Terms and credit

balances.

|

|

9. Default

Extra Charge For Terms Code?

|

Does

not apply to deposit handling

|

Set-Up Rules To Remember:

A.

When Reference

Field Flag = N.

- System

follows the Standard Processing Method.

- Data entered in the COP

Billing Screen will not update A/R until the invoice is posted.

- Fields

5 through 8 will be disabled.

- Fields

2 and 3 will be functional if flagged Y. Any information entered into the

Billing Screen will carry over to the invoice when the order is selected

for billing.

- Unless

you want to hold checks until invoicing occurs, you must create open item

cash receipts in A/R and then reapply once the invoices are posted.

B. When

Reference Field Flag = Y

- The

system will not post or create any transactions for the amount entered in

the Amount Paid field.

- When

the invoice is posted, the system will automatically perform a Re-Apply

for the open Payment/Open Credit referenced in the billing screen and

match it to the invoice.

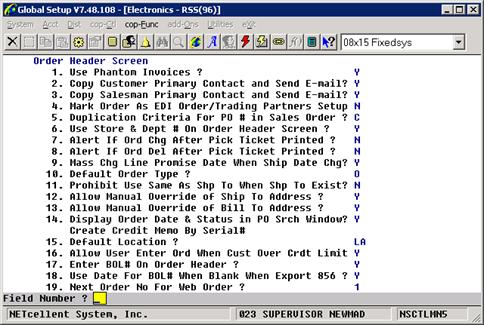

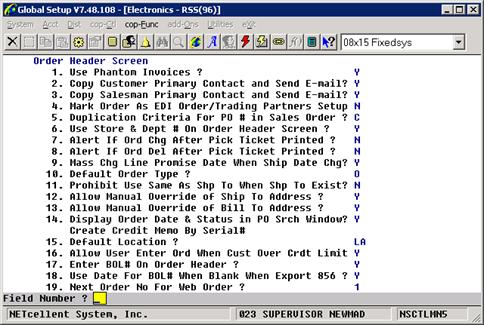

Elliott

COP is a feature rich module with many features and functions that are

controlled in the Order Header, Order Line Item, and Order Billing Screens.

Rather than enabling these features and functions that may not apply to all

users, we give the user the option to select only those that apply to them or

that they can use to better meet their needs and functionality. The COP

managers or owners should review the options available with management and COP

users, and then incorporate the options selected into their Procedures and

Policies Manual.

Setup Instructions

Go to Elliott main Menu: Util-setup

®

Global setup ® cop-Function ® order Header screen. The following setup screen

will appear:

Entry Field Descriptions

|

NAME

|

DESCRIPTION

|

|

1.

Use Phantom Invoices

|

Answer

“Y” to enter a Phantom Order and print a Phantom Invoice(s). The purpose for

Phantom Orders is for Proforma or consignment purposes. You can control the

files that will update after posting. In most cases, when posting Phantom

Invoices, you should not update any existing Elliott data files.

|

|

2. Allow

Users To delete COP Order

|

Select

from the following options:

“L”

= List of Users to Allow. Allows you to define 5 supervisors (users)

authorized to delete COP orders.

“Y”

= Allows users to delete orders.

“N”

= System will not allow deletion of orders.

|

|

3. Allow

Users To enter Ord When Cust Over Crdt Limit

|

Select

“Y” to allow user to enter an order when customer is over their credit limit.

Select “N” to

prevent processing orders when a customer is over their credit limit.

Note:

If there is a credit problem, the Credit Check and Release feature can

automatically put an order on hold after the order has been entered.

|

|

4. Mark

Order As EDI Order/Trading Partners Setup

|

See

explanation at the end of Entry Field Descriptions.

|

|

5. Duplication

Criteria For PO# in Sales Order

|

This feature checks for duplicate purchase orders and gives

you the following duplication checking criteria:

1.

N=None

2.

2.

P=P.O.# Only

3.

C=Customer

4.

S= Per

Ship To.

“P” checks for the P.O. # only, “C” checks if the

P.O. # has already been entered for that customer, and “S” checks against the

P.O.#, Cust#, and Ship-To#.

If you do want to check for duplication PO Number

in COP set this flag to “N”.

When

you enable the checking of duplicate PO#, you also enable the feature of

searching by PO# and Ship-To# in COP Order Inquiry and Order Entry Change

Mode. If “N” is selected, it will disable both features.

|

|

6. Use

Store & Dept# In Order Header Screen

|

If

you need to identify a Store or Department Number on your order and print

this information on the invoice, set this flag to “Y”.

|

|

7. Alert

If Ord Chg After Pick ticket Printed

|

If

“Y”: When you go to change an order after the picking ticket has been

printed, the system will prompt you with a message that the order has been

picked. If this occurs, the Shipping Department should be made aware of the

changes and that a new Picking Ticket is to be printed. In most situations

when you go change an order, you should be alerted if the order has been

picked. Therefore, we suggest you to enable this feature.

|

|

8. Alert

If Ord Del After Pick Ticket Printed

|

Select

“Y” to have the system notify you that you are deleting an order for which a

Picking Ticket has been printed. If this occurs, you should verify with the

Shipping Department if the order has been picked and/or shipped. We suggest

that you turn on this feature.

|

|

9. Mass

Chg Line Promise Date When Ship Date Chg

|

Elliott controls the ship date at the order line item level

by using the “Promise Date”. This feature allows a mass change of the line

items Promise Date to match a new Ship Date.

If you select “Y”, then during order header change of the

ship date field, a window will popup and ask if you want to do a mass change

to the line items.

You

should enable this feature if most of your orders ship date is identical for

all line items on that order.

Do

not enable this feature if you need to process line items with an individual

“Promise Date”.

|

|

10.

Default Order Type

|

The

Elliott default Order type is “O”. However, there are many companies who

process mostly “I” type orders for immediate invoicing or over the counter

sales, and the default of “O” causes an inconvenience. This feature gives

you the option to set a default for “O” = Order, “I” = Invoice, “Q ”= Quote,

or “C”= Credit Memo.

|

|

11. Prohibit

Use Same As Ship To When Ship To Exist

|

This

is a security feature to prevent shipping an order to an address other than

the address setup for the Ship To Number. Select “N” to disable manual

override, or “Y” to allow manual override. If a company is concerned that an

order may ship to a non-valid Ship to Address, they should set this flag as

“N”.

|

|

12. Allow

Manual Override of Ship To Address

|

There are many companies who want orders shipped only to

their stores or branches, but never to their headquarters. This function will

prevent shipping to the Customer headquarters if a Ship To Number has been

setup.

Select “Y” to enable this function. If the

customer needs an occasional order shipped to their main location, they must

setup a Ship To Number for their main location.

|

|

13. Allow

Manual Override of Bill To Address

|

This

is a security feature to prevent billing an order to an address other than

the default Bill To Address. Select “N” to disable manual override, or “Y”

to allow manual override.

|

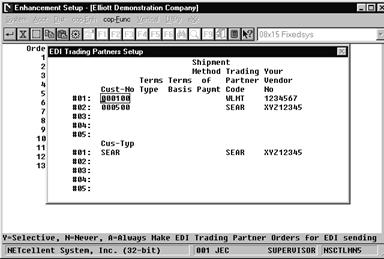

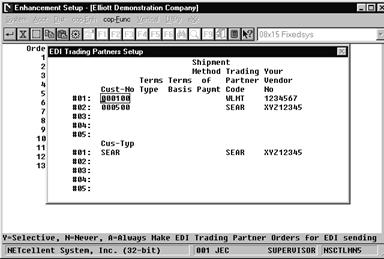

4. Mark an order

as an EDI order/Trading Partners Setup.

This field involves

two settings:

1. Mark an

order as an EDI Order: Value defined in this field

2. Trading

Partner Setup: Defined in a popup window

All orders that come

into Elliott through EDI will be marked as an EDI orders automatically, (a

hidden flag in order header). All orders marked as EDI can be invoiced to

trading partner as an EDI invoice as well. However, if you need to manually

enter orders for your EDI trading partners, the question for you is whether you

need to invoice your EDI trading partners through EDI as well? If your answer

is “Y”, then by default the order you manually enter for your trading partner

will not be marked as EDI. As a result, that order will not be invoiced to

your EDI trading partner.

To solve this

problem, our order entry system needs to know who is your EDI trading partner.

These trading partners can be setup in “Trading Partner Setup Window” which

will popup after you press enter on the “Mark an Order” field.

If you do not use

EDI, or if you do not need to invoice your trading partners through EDI, answer

“N” to this field.

If you are using

EDI, and need to invoice your trading partners through EDI for manually entered

orders, answer “A” (Always) to this field. All orders you manually entered for

your EDI trading partners will be marked as EDI orders automatically.

If you are using

EDI, and have multiple EDI trading partners where some require you to invoice

them through EDI, and some don’t, you might consider using “Y” (Selective) in

this field. Selective allows the system to prompt you during order entry to

determine “If you wish to make this order EDI?”

Once you enter a

value into this field. The Trading Partner Setup Windows will popup.

Cust-No. = This

is your Partners Customer number as defined in A/R.

Terms Type = Leave

Blank

Terms Basis = Leave

Blank

Payment = Leave

Blank

Partner Code = This is your Trading Partners

EDI Customer # as defined by your EDI translator software.

Vendor No. = This

is your Vendor number for your trading partner.

Under most situations, you

can leave the Terms Type, Terms Basis and Shipment Method of Payment fields

blank. If your EDI translator software has properly defined the map for your

trading partner, this information can be picked up from your EDI translator

software side.

Partner code is defined by your EDI translator software. Under

most situations, your EDI translator software does not know the internal

customer number you are using for your trading partner. They may use their

Internal code like “WLMT” to stand for Wal-Mart. Therefore, we need a cross

referencing capability between Elliott’s internal customer number and EDI translator

software’s customer number. You need to verify with your EDI software provider

for their internal customer number for your trading partner.

You can

define up to 5 customer numbers as your trading partners. In some situations,

you may have multiple customer accounts corresponding to the same trading

partner. You may use a unique customer type to represent this trading partner

and make sure each customer account for this trading partner is setup correctly

with this customer type. This will work for EDI, if you only need to invoice

EDI and do not need to import EDI orders.

Cust-Type = This

is a unique customer type defined in A/R for those Trading Partners who ship to

multiple branches or other locations.

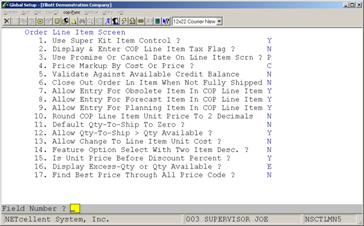

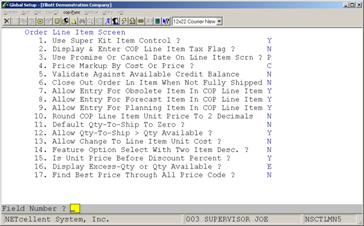

Elliott

COP is a feature rich module with many features and functions that are

controlled in the Order Header, Order Line Item, and Order Billing Screens.

Rather than enabling these features and functions that may not apply to all

users, we give the user the option to select only those that apply to them or

that they can use to better meet their needs and functionality. The COP

managers or owners should review the options available with management and COP

users, and then incorporate the options selected into their Procedures and

Policies Manual.

Set Up Instructions

Go to Elliott Main Menu: Util-setup

®

Global Setup® cop-Func ® order Line

item screen. The following setup screen will appear:

Entry Field Descriptions

|

NAME

|

DESCRIPTION

|

|

1. Use

Super Kits Function

|

Answer

“Y” to enable this function.

This

function will allow you to select the components of a KIT item during order

entry. If you have already defined a KIT file, the system will copy over

this structure with the predefined components, but you have the option to

change, delete, or add component items. If you have defined a KIT parent

item in the item master file, but have not defined a KIT file, the system

will allow you to search that KIT item using the [F7] key. The system will

then display an empty KIT window giving you the option to enter any

components for this KIT item. The Super KIT Item function is a powerful tool

for light assembly/manufacturing companies who often have the need to change

Bill of Material configurations.

|

|

2. Display

& Enter COP Line Item Tax Flag

|

If

you would like to be able to see the line item tax flag and access the field

during order line entry, answer “Y” to this question.

|

|

3. Use

Promise Or Cancel Date On Line Item Screen

|

There

are two date fields in the order line item file: “Request Date” and “Promise

Date”. Request date is the date that customer requests you to ship the

goods. By default, promise date will be equal to request date unless you

change it. You will normally change the promise date when you can’t ship

goods to your customers by their request date. With your customer’s

permission, you change the promise date to a later date when you will be able

to ship. Picking Ticket printing is based on “Promise Date” for selecting

line items to print.

Some

businesses, especially large chain stores, may give you a request date for

shipment and a cancellation date to cancel the order if you do not ship by

that date. If you set this flag to “C”, then system will use “Promise Date”

field as Cancel Date with a literal change to “Cancel Date”. If so, the

picking ticket printing is based on “Request Date” for selecting, not “Cancel

Date”. The default value for this field is “P” for “Promise Date”.

|

|

4. Price

Markup by Cost Or Price (Pricing Codes)

|

C = Cost: Price

Code markup based on a cost markup.

P = Price: Price

Code markup based on a base line item price

in the Inventory Item file.

Default

value is “C” for cost.

|

|

5. Validation

Against Available Credit Balance

|

If

you maintain tight controls on customers credit limit, you should turn on

this feature and let the system check the credit balance on a line item by

line item basis. As each line item is entered, the system checks if the

credit limit is exceeded with this line. When the credit limit is exceeded

with this line item, the system gives you a warning message, but does not

stop you from additional line item entry. It is helpful for the order entry

person to know that customer’s credit limit has just been exceeded and no

more line items should be placed on this order.

|

|

6. Close

Out Order Line Item When Not Fully Shipped

|

Even

though the customer may allow you to back order, he may request that you to

close out a line item that has been back ordered. By enabling this flag, the

system will give you option to do so in the change mode of order entry

processing.

|

|

7. Allow

entry for Obsolete Item In COP Line Item

|

If you enter

an item that is obsolete the system will give you a warning message, but let

you proceed. By answering “N” to this field, the system will not allow entry

of obsolete items.

Note: Items are marked

Obsolete in the Inventory item master

file.

|

|

8. Allow

Entry For Forecast Item In COP Line Item

|

Similar

to previous question. Answer “N” to this field to prevent order entry for

forecast items.

|

|

9. Allow

entry For Planning Item In COP Line Item

|

Similar

to previous question. Answer “N” to this field to prevent order entry for

planning items.

|

|

10. Round

COP Line Item Unit Price to 2 Decimals

|

The Elliott

unit price allows up to 4 decimal points. When the discount or markup setup

in price codes are by a percentage, the unit price calculated may carry over

to three or four decimal points. If you require or prefer rounding the unit

price to two decimal points, answer “Y” to this question. Default value is

“N”.

|

|

11. Default

Qty-To-Ship To Zero

|

Certain

business always back order items when an order is first entered. Make-to-order

businesses, or manufacturers, who start to produce items as they receive the

order, usually do this. Answer “Y” to make quantity to ship as zero and back

order the line item by default.

|

|

12. Allow

Qty-To-Ship > Qty Available

|

Select “Y” to enable this feature. This feature addresses

the situations when you want to bill an order regardless if you have the

Quantity available, or when you physically have the quantity available on

hand. Qty To Ship > Qty Available occurs from inaccurate inventories or when

quantity has already been allocated, (Qty Available = Qty On Hand – Qty

Allocated).

Select

“N” if you wish to have a tighter control with inventory and force the

inventory to be accurate before shipment can happen. The default is “Y”.

|

|

13. Enter

Line Item Unit Cost Unconditional

|

When

processing a line item, the system by default skips over the Unit Cost

field. However, you can go back after you have completed the screen and

change the unit cost. If you always need to change this field as you are entering

line item data, select “Y” to enable this feature.

|

|

14. Feature

Option Select With Two Line Item Description

|

When

selecting Feature Options, the system by default will only display the first

line of the item description. If you need to display both lines of

description, select “Y” to enable this feature, otherwise select “N”.

|

|

15. Is

Unit Price Before Discount Percent

|

Select

“Y” to use the standard discount logic. When an order is discounted at Order

Entry time, the Unit Price field in the line entry screen will not reflect

the discounted price, instead the line item discount percent will default

to the discount in the Order Header, To know what you are selling the item

for, you must divide the extended price by the quantity ordered.

If

you select “N”, then the Unit Price in the line entry screen will reflect

the discounted price based on order header discount percent and the lien

item discount percent will default to 0. This is a more convenient way of

seeing what you are billing the item for rather than having to figure out the

net unit price that you are billing for. It is also easier to communicate

with customer either verbally or through invoicing for the net unit price

that we are charging the customer.

|

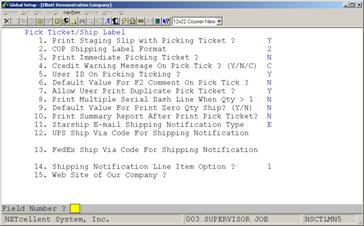

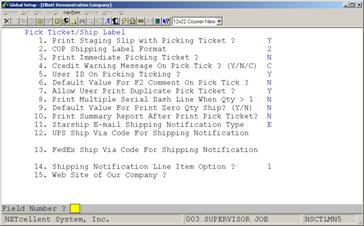

Elliot Main Menu à

Util setup à Global setup à cop-Func à

Pick Ticket/ship label

Entry Field Descriptions

|

Name

|

Description

|

|

1.

Print Staging Slip with Picking Ticket?

|

This

feature is used to print a consolidated pick ticket (staging slip) for

multiple orders. If you have a large warehouse and the number of orders is

huge, the traditional method of using picking ticket to pick order one at a

time is not efficient. A better method is to pick all orders in a batch in

one run and place the goods in a staging area. From staging area, you can

pick your individual order much quicker than go through the entire

warehouse. Thus, we call this feature Staging Slip. Some people may

refer this as “Wave Pick”. This feature is very useful for

distributors with large-sized warehouses.

There

are two different modes for printing a staging slip:

a.

Automatic mode:

the staging slip will be automatically printed right after the picking ticket

is printed.

b.

Manual mode:

orders can be manually entered one by one, and then the staging slip is

printed.

Note: If picking sequence is not used, then line items will

be sorted by item number on staging slip.

1.

Automatic Mode

Automatic

mode occurs in the Print Picking Tickets. In order to use Print

Staging Slip in this mode, this feature must be enabled. After the

picking ticket is printed, if you hit the ESCAPE key or F10, it

will automatically ask you if you wish to print the staging slip.

2.

Manual Mode

This

mode allows you to manually enter one order after another for printing

staging slips.

|

|

2.

COP Shipping Label Format

|

Allows

up to four label sizes

|

|

3.

Print Immediate Picking Ticket?

|

Some

companies may require the shipment take place right after the order is

entered. Answer “Y” to enable printing of picking ticket immediately

where system will ask you “Do you wish to print pick ticket immediately?”

after an order is entered.

|

|

4.

Credit warning message on Picking ticket?

|

“Y’ =

“N” =

“C”

=

|

|

5.

User ID on Picking ticket?

|

Select

“Y” to print the user who entered the order.

Select

“N” to disable/

|

|

6.

Default value for F2 comment on Picking ticket

|

Default

is “N”. To print F2 comment, enter “Y”.

|

|

7.

Allow User to print duplicate Pick ticket?

|

Default

is “N”. Select “Y” to allow printing a duplicate ticket. Caution:

Duplicate tickets could result in double shipments to customers.

|

|

8

Print Multiple Serial Dash Line When Qty. > 1

|

The

default Picking ticket logic only gives you one dash line, (15 characters),

even if you quantity to ship is greater than one. This setup flag prints a

serial number dash line for the total Quantity to ship, i.e., if item has

qty-to-ship of 24, then it will print 24 dash lines to enter all serial

numbers. Additionally, you can print the serial number dash lines in two

columns format to reduce the spacing requirement.

Select

“Y” to print one dash line per serial number, Select “T” to

print the serial number dash lines in two columns format, or select “N”

if you only need one dash line regardless of qty-to-ship.

|

|

9.

Default Value for Print Zero Qty. Shipped Y or N

|

|

|

10.

Print Summary Report after Print Pick Ticket?

|

|

|

11.

Starship E-Mail Shipping Notification Type

|

E

= Manifest Event (User defined e-mail)

H

= Hard coded (Predefined by Elliott w/links to shipper)

|

|

12.

UPS Ship Via code For Shipping Notification

|

Enter

UPS shipping codes for which you want to send e-mail shipping notification

|

|

13.

Fed Ex Ship Via Code For Shipping Notification

|

Enter

Fed EX shipping codes for which you want to send e-mail shipping notification

|

|

14.

Shipping Notification Line Item Option

|

Determines

what orders/items will qualify for shipping notification.

1

= Selected or Invoice Items

2

= From Shipping Verification program

3

= From Picking ticket

4

= All N0n-Backordable Items

5

= Do Not Print

|

|

15.

Web Site Of Our Company

|

|

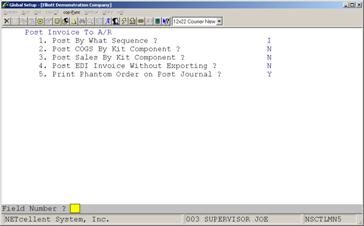

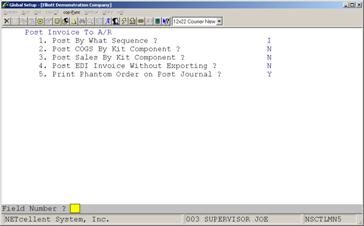

Figure 5H.1

Entry Field Descriptions

1.

Post invoices by invoiced

sequence, or order sequence.

By

default, COP Post Invoice to A/R will be posted by order number sequence. If

you would rather post it by invoice number sequence, you can set this flag to

“I”.

2.

Post COGS by Kit Component.

By

default, COP posting will roll up the component cost for a kit item and post to

the inventory and cost of good sold accounts based on the kit item’s material

cost type and product category. If you would rather post inventory and COGS by

kit components, answer “Y” to this question. The system will distribute to G/L

based on the KIT component’s cost of goods sold accounts defined in the product

category.

3.

Post Sales by Kit Component.

By

default, COP posting will post the sales distribution by kit item’s product

category. If you like to analysis your sales by kit components, you can set

this flag to “Y”, then not only the sales distribution will be posted by kit

components, it will also post the components to the Sales History Trx File, and

update the Items’ Accumulator (ytd, ptd sales cost), except in the Invoice

History file.

4.

Post EDI Invoice Without

Exporting?

For an imported EDI order you have

the option to export it to an EDI 810 Invoice. However, once an invoice has

been posted you will not be able to export to an EDI 810 through the regular

process. Therefore, by setting this flag to “N” will prevent potential error

where the posting is taking place before the exporting of EDI 810 Invoice.

When an EDI order is exported, the order will be marked (a hidden flag), then

the invoice can be posted. However, in some situation you can’t set this flag

to “Y” for it will bring more problems than it try to solve. In those

situations, you have to use procedure control: meaning you have to ensure that

the EDI 810 Export is done before the posting through your internal procedure.

The following table will give you a good guideline for setting this flag:

|

Scenario

|

Procedure Control

|

Flag Control

|

|

You

You are not using EDI

|

Set this flag to “Y”

|

Set this flag to “Y”

|

|

You have one or more EDI trading partners,

hey all require 810 Invoice.

|

Set this flag to either “Y” or “N”.

Preferable to set this flag to “N” to prevent error.

|

Set this flag to “N”.

|

|

You have multiple EDI trading partners.

Some of them require 810, some of them don’t.

|

Set this flag to “Y”. You must use

Procedure control in this case.

|

Set this flag to “Y”. You can’t rely on

flag control to prevent error and must use internal procedure control.

|

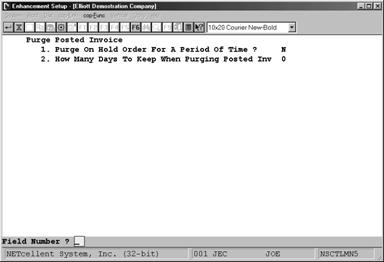

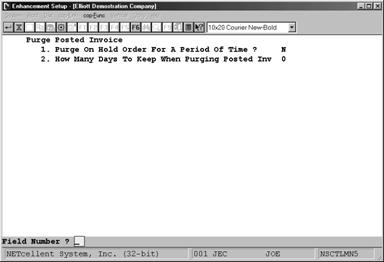

Purge Posted Invoice

The

purpose of this feature is to automate the purge process via Deferred

Processing without losing the time window of history that you wish to keep. To

make this possible, we allow you to define a time window for history to keep.

Purge Posted Invoices

Setup Screen

Field Entry Descriptions

1. Reserved for future

use.

2. How Many Days To

Keep When Purging Posted Invoices?

With

the purpose of this feature being to automate the purge process via Deferred

Processing without losing the time window of history that you wish to keep, we

make it possible by allowing you to define a time window for history to keep.

For Example:

a.

Define the numbers of days to

keep history when you purge, (90 Days).

b.

Purge Process, (recurring daily,

weekly, monthly, or quarterly) is set up for Deferred Processing with a purge

cut-off date well set into the future, 12/31/30.

c.

The process would normally purge

all posted invoices through 12/31/30 but since we made the 90 “Days To Keep” a

condition, it will keep all history for 90 days prior to the system date and

purge everything else.

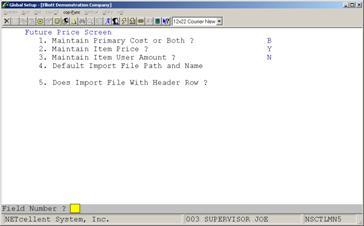

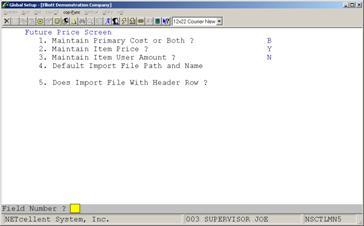

Setup of Future Price

Before using this

function, you must define and enable your default parameters in the setup

process. To do this, go to: Main Menu -> Util Setup -> Global setup à Cop-Func

-> Future Price. The following screen will appear:

Future Price Screen Setup

Entry Field Description

|

NAME

|

DESCRIPTION

|

|

1. Maintain

Primary Cost of Both?

|

Elliott

maintains both FOB and Landed Cost, and these are your Primary and Secondary

Costs. Whichever is the Primary or Secondary cost is dependent upon how you

have setup the Landed Cost function. For these costs you have an Average

Cost, Last Cost, and Standard Cost. This enhancement will only update the

Standard cost.

Select

“P” for Primary, Select “B” for Both, or “N” for None if you do not need to

maintain future standard costs.

|

|

2. Maintain

Item Price?

|

Select “Y” to maintain the future price. On the specified

date, the new price becomes effective after posting.

|

|

3. Maintain

Item User Amount?

|

The Item User

Amount is a user definable field. If you need to update this field on a

future date, select “Y” to include this field for maintenance in the future

price function. Refer to the System Manager Manual on how to use Item User

Amount.

|

|

4.

Default Import File Path/Name

|

|

|

5.

Does Import file With Header row

|

|